Model W1777 2

1

⁄

2

" 16 Gauge Finish Nailer

-14-

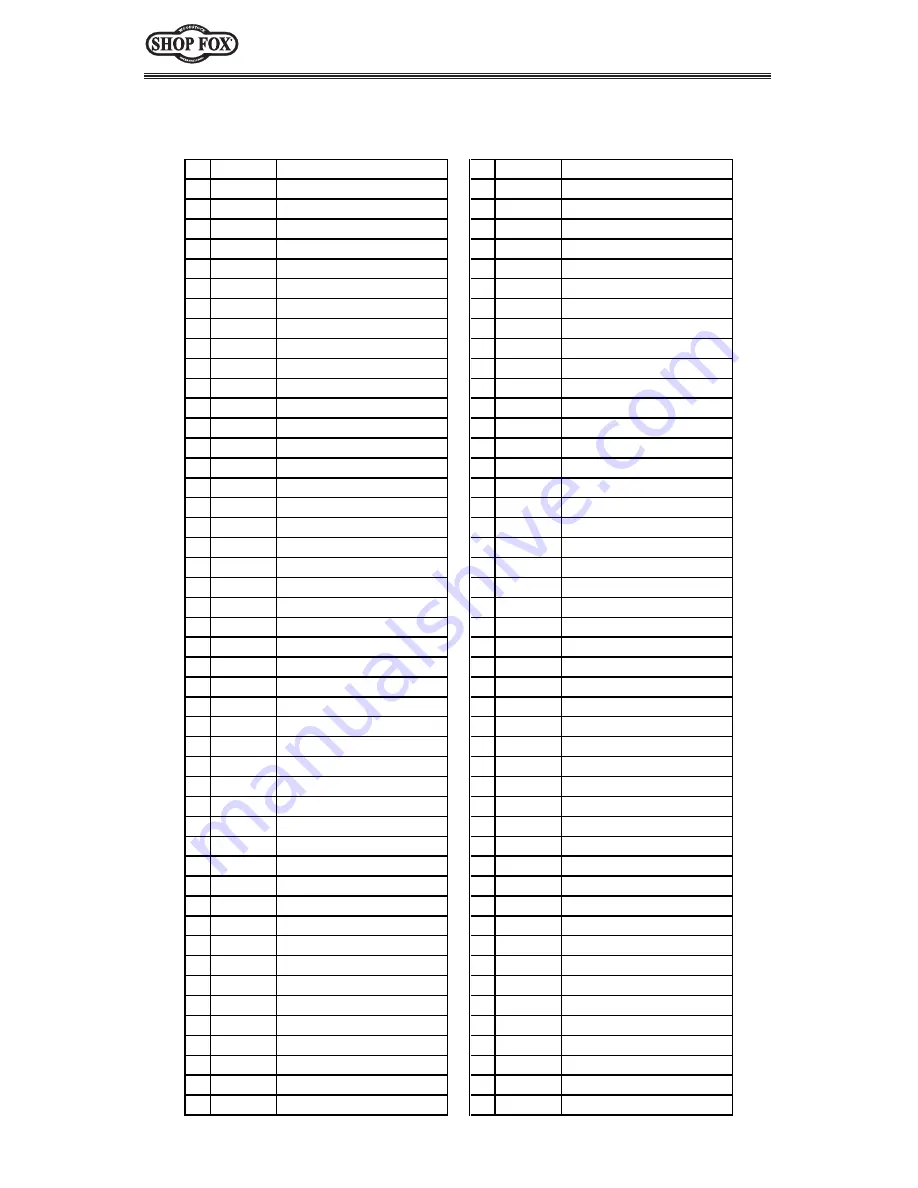

W1777 PARTS LIST

REF PART�#

DESCRIPTION

REF PART�#

DESCRIPTION

1

XPAW05M HEX�WRENCH�5MM

49 X1777049 STEEL�BALL�DW=2

2

XPAW04M HEX�WRENCH�4MM

50 X1777050 SPECIAL�SCREW

3

X1777003 CARRYING�CASE

51 X1777051 SUPPORT�BRACKET

4

X1777004 AIR�PLUG�COVER

52 X1777052 CONNECTING�BRACKET

5

X1777005 AIR�PLUG

53 X1777053 ROLL�PIN�3�X�28

6

X1777006 END�CAP

54 X1777054 O-RING�2�X�2.5

7

X1777007 END�CAP�GASKET

55 X1777055 TRIGGER�PIN

8

X1777008 RUBBER�GRIP

56 X1777056 SAFETY�BRACKET

9

XPLN03M LOCK�NUT�M6-1

57 X1777057 TRIGGER

10 X1777010 SUPPORT�SEAT

58 X1777058 PIN�C3�X�17

11 XPW03M

FLAT�WASHER�6MM

59 X1777059 SWITCH�VALVE�SEAT

12 XPSB02M CAP�SCREW�M6-1�X�20

60 X1777060 O-RING�20.3�X�2.3

13 XPSB17M CAP�SCREW�M4-.7�X�10

61 X1777061 SWITCH�VALVE�STEM

14 X1777014 SUPPORT�BRACKET

62 X1777062 O-RING�2.5�X�1.5

15 X1777015 LATCH�LEVER

63 X1777063 SWITCH�SPRING

16 X1777016 PLATE

64 X1777064 TRIGGER�VALVE�GUIDE

17 X1777017 PUSHER

65 X1777065 O-RING�9�X�1.8

18 X1777018 FLAT�COILED�SPRING

66 X1777066 O-RING�6.4�X�2

19 X1777019 BRACKET

67 X1777067 O-RING�6.2�X�1.8

20 XPRP02M ROLL�PIN�3�X�16

68 X1777068 TRIGGER�VALVE�SEAT

21 XPSB57M CAP�SCREW�M3-.5�X�6

69 X1777069 O-RING�17.4�X�1.5

22 X1777022 LOCK�NUT�M4-.7

70 X1777070 O-RING�15�X�2.65

23 X1777023 MAGAZINE

71 X1777071 GUN�BODY

24 X1777024 NAIL�PLATE

72 X1777072 CYLINDER�COVER�GASKET

25 X1777025 COMPRESSION�SPRING

73 X1777073 SPECIAL�WASHER

26 XPSB17M CAP�SCREW�M4-.7�X�10

74 X1777074 BUMPER

27 X1777027 PIN

75 X1777075 MAIN�PISTON

28 XPEC01M E-CLIP�3MM

76 X1777076 O-RING�31�X�3.55

29 XPSB50M CAP�SCREW�M5-.8�X�10

77 X1777077 CYLINDER�COVER

30 X1777030 RELEASE�LATCH

78 X1777078 O-RING�42�X�3.55

31 XPSB18M CAP�SCREW�M4-.7�X�8

79 X1777079 O-RING�42�X�2.5

32 X1777032 NOSE�COVER

80 X1777080 COLLAR

33 X1777033 SPACER�PIN

81 X1777081 O-RING�60�X�2.5

34 X1777034 E-CLIP�2.5MM

82 X1777082 SWITCH�VALVE

35 X1777035 SPACER

83 X1777083 O-RING�48.7�X�2.65

36 X1777036 DRIVER�GUIDE

84 X1777084 O-RING�38�X�3.5

37 X1777037 BLOCK

85 X1777085 O-RING�25�X�3.5

38 X1777038 COMPRESSION�SPRING

86 X1777086 COMPRESSION�SPRING

39 X1777039 PLATE

87 X1777087 O-RING�18�X�2.65

40 XPSB41M CAP�SCREW�M4-.7�X�14

88 X1777088 CYLINDER�COVER

41 X1777041 SAFETY�STAND

89 XPLW01M LOCK�WASHER�5MM

42 X1777042 ADJUSTING�NUT

90 XPSB38M CAP�SCREW�M5-.8�X�25

43 X1777043 DIRECTION�STAND

91 X1777091 BUMPER�WASHER

44 X1777044 DIRECTION�PIN

92 X1777092 EXHAUST�PORT

45 XPEC09M E-CLIP�6MM

93 X1777093 SPECIAL�CAP�SCREW

46 X1777046 PIN

94 X1777094 SAFETY�GLASSES

47 X1777047 SAFETY�SEAT

95 X1777095 PISTON�REPAIR�KIT

48 X1777048 COMPRESSION�SPRING

96 X1777096 O-RING�REPAIR�KIT