Model W1781 21˚ Framing Nailer

-8-

OPERATIONS

Loading

When replacing nails in your Model

W1781, follow these guidelines:

Type: .............................. Round Head

Angle: ....................................... 21°

Diameter: ............................... 0.113"

Length: ................................. 2"–3

1

⁄

2

"

Capacity: .............................. 75 Nails

To load your nailer, do these steps:

1.

DISCONNECT NAILER FROM THE AIR

SUPPLY!

2.

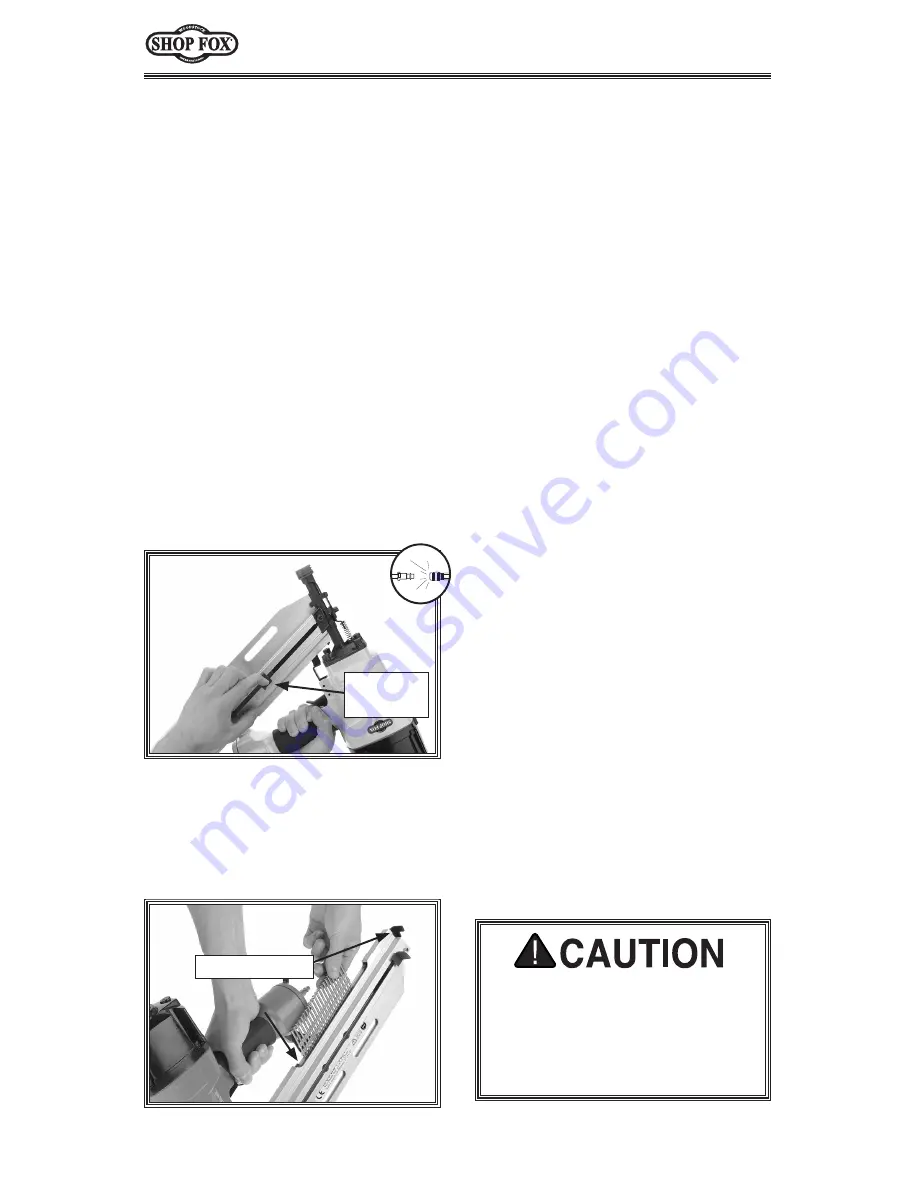

Slide the magazine back, as shown in

Figure 3

, until it locks in place.

If you have not read the safety

instructions in this manual, do not

operate the nailer.

Before you operate your nailer, place five

to six drops of the included oil into the

quick connect fitting where the nailer

connects to the air supply, unless using a

lubricator unit.

To operate your nailer, do these steps:

1.

Connect the air supply to the quick

connect fitting.

2.

To test for proper nail penetration,

hold the nailer perpendicular to the

surface of a piece of clean scrap

wood that is thick enough for the

length of nails you have loaded.

Operating

4.

Slide the nails all the way down to

the nose of the nailer.

5.

With one hand on the magazine

handle for control, release the

magazine catch and slowly allow the

magazine to press against the nails.

Note:

Releasing the magazine catch

and allowing it to "snap" in position

causes undue wear and can lead to

premature failure.

Figure 4.

Loading nails into magazine.

Magazine Catch

3.

Insert a strip of nails, pointed-end

down, into the magazine as shown in

Figure 4

.

Figure 3.

Sliding magazine pusher back

and engaging catch lever.

Magazine

Handle

DO NOT place your hands near the

nail point of entry. A nail can deflect

and tear through the surface of the

workpiece, puncturing your hand or

fingers.