Model W1793/W1794 Professional Spray Gun

-12-

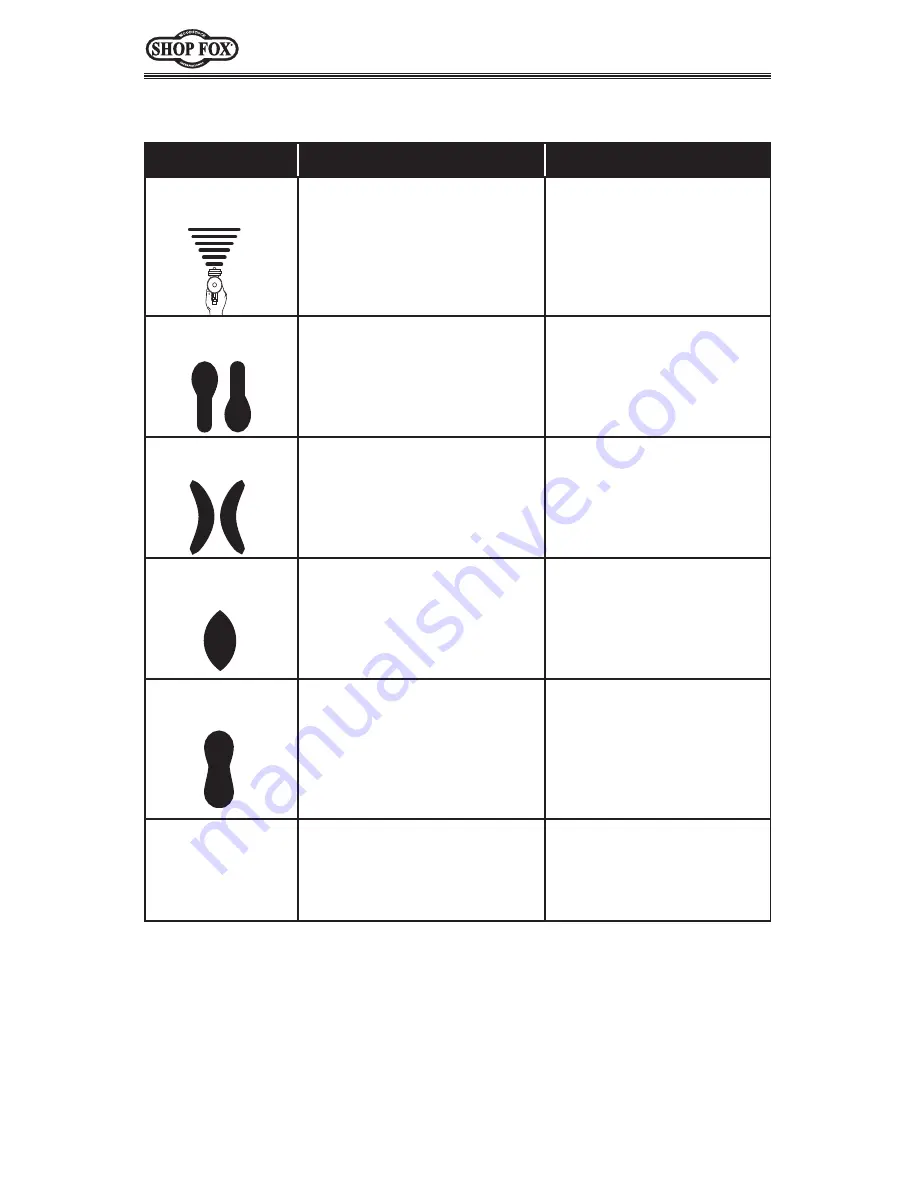

Troubleshooting

Symptom

Possible

Cause

Possible Solution

Fluttering or

Spitting spray.

1. Dry or worn fluid tip seat

permits air to seep into fluid

passage.

2. Material level too low.

3. Fluid tip or strainer obstruct-

ed.

4. Dry needle packing.

1. Tighten fluid tip or replace

seat with new one.

2. Add material.

3. Clean.

4. Lubricate needle.

Uneven top or bot-

tom pattern.

1. Atomizing cap holes are

obstructed.

2. Build-up on top or bottom of

fluid tip.

3. Build-up on atomizing cap is

on needle seat.

1. Clear holes.

2. Clean.

3. Clean.

Right or left arc

pattern.

1. Left or right side horn holes

are plugged.

2. Build-up on left or right side

of fluid tip.

3. Build-up of material inside

atomizing cap.

1. Clear holes.

2. Clean.

3. Clean.

Heavy deposit of

material in center.

1. The material flow exceeds

the atomizing cap capacity.

2. Inlet air pressure is too low.

3. Material is too thick.

1. Lower fluid flow.

2. Increase inlet air pressure.

3. Thin material.

Narrow center pat-

tern.

1. Volume control turned in too

far.

2. Inlet air pressure too high.

3. Fluid pressure is too low.

4. Material is too thin.

1. Increase volume.

2. Reduce inlet air pressure.

3. Increase fluid pressure.

4. Adjust material.

No spray output.

1. No pressure at gun.

2. Fluid passages dirty.

3. Fluid control closed.

4. Out of paint.

1. Check air supply.

2. Clean gun, remove any

obstructions.

3. Open.

4. Refill.

Summary of Contents for SHOP FOX W1793

Page 2: ......