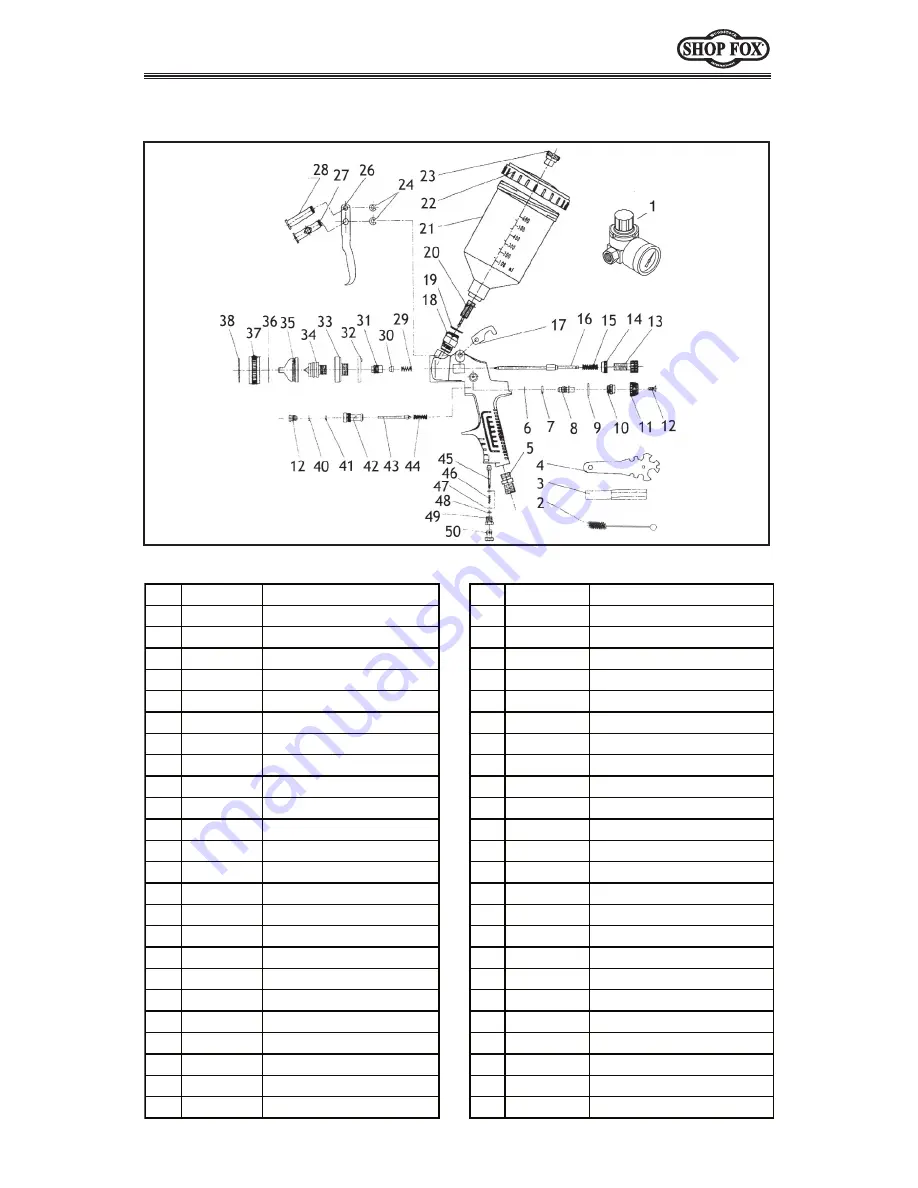

Model W1793/W1794 Professional Spray Gun

-15-

W1794 PARTS LIST

REF PART

�

#

DESCRIPTION

REF PART

�

#

DESCRIPTION

1

X1794001

AIR

�

REGULATOR

27

X1794027

TRIGGER

�

LEVER

�

2

2

X1794002

BORE

�

BRUSH

28

X1794028

TRIGGER

�

LEVER

�

1

3

X1794003

BAFFLE

��

WRENCH

29

X1794029

LOCKING

�

SPRING

4

X1794004

TOOL

�

WRENCH

30

X1794030

PAINT

�

NEEDLE

�

WASHER

5

X1794005

AIR

�

INLET

�

JOINT

31

X1794031

DIRECTION

�

SCREW

6

X1794006

RETAINER

32

X1794032

BAFFLE

�

WASHER

7

X1794007

O-RING

�

6

�

X

�

2

33

X1794033

BAFFLE

8

X1794008

PATTERN

�

ADJ

�

SCREW

34

X1794034

FLUID

�

NOZZLE

�

1.4MM

9

X1794009

SPECIAL

�

WASHER

35

X1794035

ATOMIZATION

�

CAP

10

X1794010

PATTERN

�

ADJ

�

KNOB

36

X1794036

FLUID

�

CAP

�

WASHER

11

X1794011

PATTERN

�

ADJ

37

X1794037

CAP

�

NUT

12

X1794012

FLAT

�

HEAD

�

SCREW

38

X1794038

PIN

�

SPRING

��

13

X1794013

FLUID

�

ADJ

�

KNOB

39

X1794039

DIRECTION

�

SCREW

14

X1794014

SEALING

�

CUP

40

X1794040

SPECIAL

�

WASHER

15

X1794015

FLUID

�

NEEDLE

�

SPRING

41

X1794041

O-RING

�

8.5

�

X

�

1.2

16

X1794016

FLUID

�

ADJ

�

NEEDLE

42

X1794042

SWITCH

�

KNOB

17

X1794017

HOOK

43

X1794043

AIR

�

VALVE

�

BODY

18

X1794018

FLUID

�

INLET

�

JOINT

44

X1794044

SWITCH

�

SPRING

19

X1794019

INLET

�

WASHER

45

X1794045

AIR

�

INLET

�

VALVE

20

X1794020

FILTER

46

X1794046

AIR

�

VALVE

�

SPRING

21

X1794021

CUP

�

600ML

47

X1794047

SPECIAL

�

WASHER

22

X1794022

CUP

�

COVER

48

X1794048

O-RING

�

2.5

�

X

�

2.1

23

X1794023

VENTILATOR

�

HEAD

49

X1794049

AIR

�

ADJUSTMENT

�

KNOB

24

X1794024

RETAINER

�

4MM

50

X1794050

AIR

�

ADJUSTMENT

�

SCREW

26

X1794026

TRIGGER

51

X1794051

O-RING

�

KIT

Summary of Contents for SHOP FOX W1793

Page 2: ......