-27-

Model W1715 (For Machines Mfd. Since 2/19)

O

PE

R

ATIO

NS

Blade.Selection

Blade.Size

The Model W1715 accepts only

1

⁄

2

" x 0.025 x 64

1

⁄

2

" blades.

Tooth.Pitch

Usually measured as TPI (Teeth Per Inch), tooth pitch

determines the size/number of the teeth. More teeth

per inch (fine pitch) will cut slower, but smoother; while

fewer teeth per inch (coarse pitch) will cut rougher, but

faster.

As a general rule, choose blades that will have at

least three teeth in the material at all times. Use fine

pitched blades on harder metals and coarse pitched

blades on softer metals. When selecting blades, refer to

Figure.

35

.

for recommended blade tooth (TPI) and speed

(FPM) based on the workpiece material.

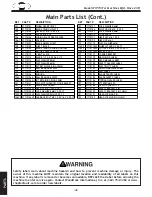

Material

TPI

FPM

Tool Steel

Stainless Steel

Bearing Bronze

24

78

Mild Steel

Hard Brass

Bronze

18

108

Soft Brass

Aluminum

Other Light

Metals

14

180

Figure.

35

.

Blade TPI and FPM chart.

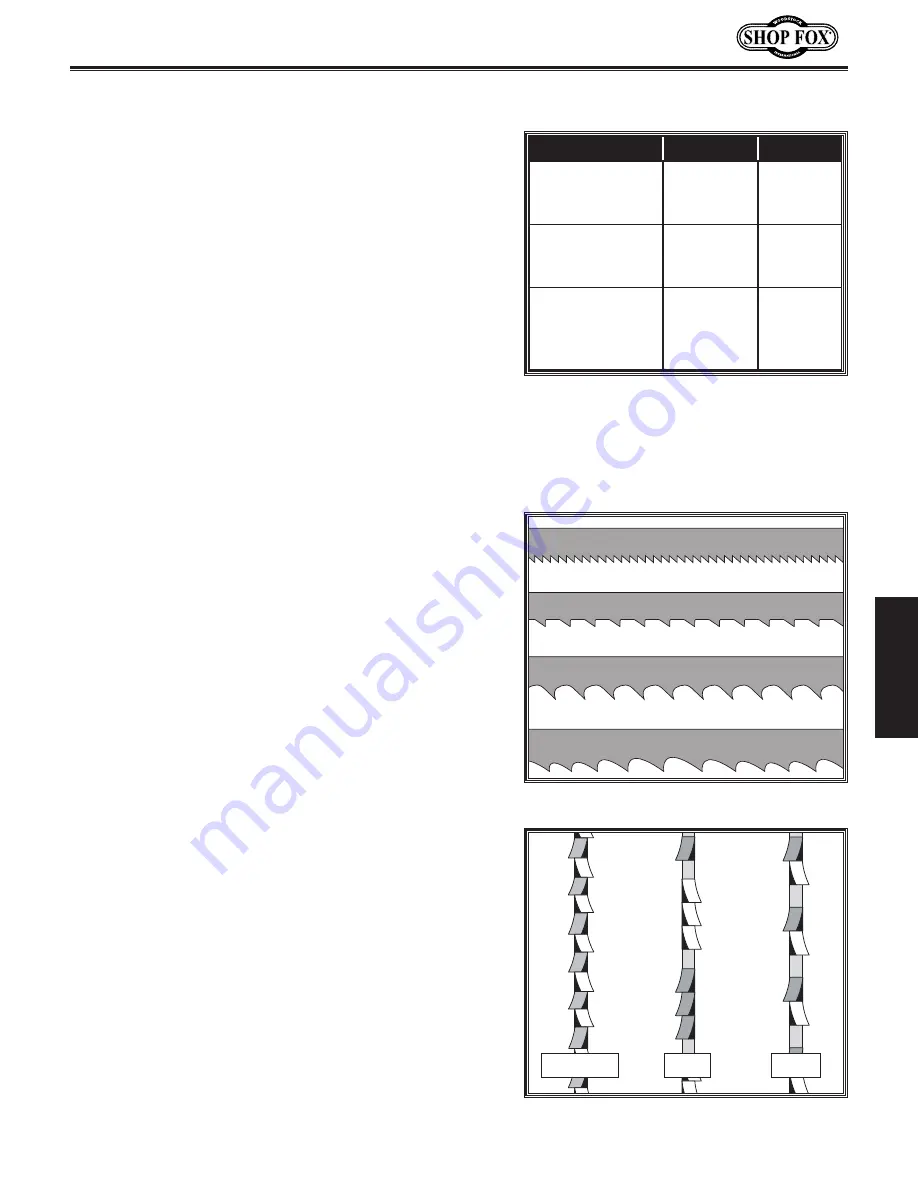

Standard (or Raker)

Skip (or Skip Tooth)

Hook (or Claw)

Variable Pitch (VP)

Figure.

36

.

Bandsaw blade tooth styles.

Figure.

37

.

Bandsaw blade tooth sets.

Alternate

Wavy

Raker

Tooth.Set

Three of the most common tooth sets are alternate, wavy,

and raker (see

Figure.

37

).

Tooth.Style

When selecting blades, another option to consider is the

shape, gullet size, teeth set and teeth angle—otherwise

known as “Tooth Style." Many blade manufacturers offer

variations of the four basic styles shown in

Figure.

36

.

Summary of Contents for W1715

Page 45: ...Model W1715 For Machines Mfd Since 9 17 ...

Page 48: ......