-33-

Model W1715 (For Machines Mfd. Since 2/19)

SE

RV

IC

E

Blade.Tension

Proper blade tension is essential to long blade life,

straight cuts, and efficient cutting times.

Two major signs that you do not have the correct blade

tension are: 1) The blade stalls in the cut and is slipping

on the wheels, and 2) the blade frequently breaks from

being too loose.

To.tension.the.blade.on.the.bandsaw,.do.these.steps:

1.

Make sure the blade is tracking properly.

2.

DISCONNECT BANDSAW FROM POWER!

3.

Loosen and slide the blade guides as far apart as

they will go then tighten them down again.

4.

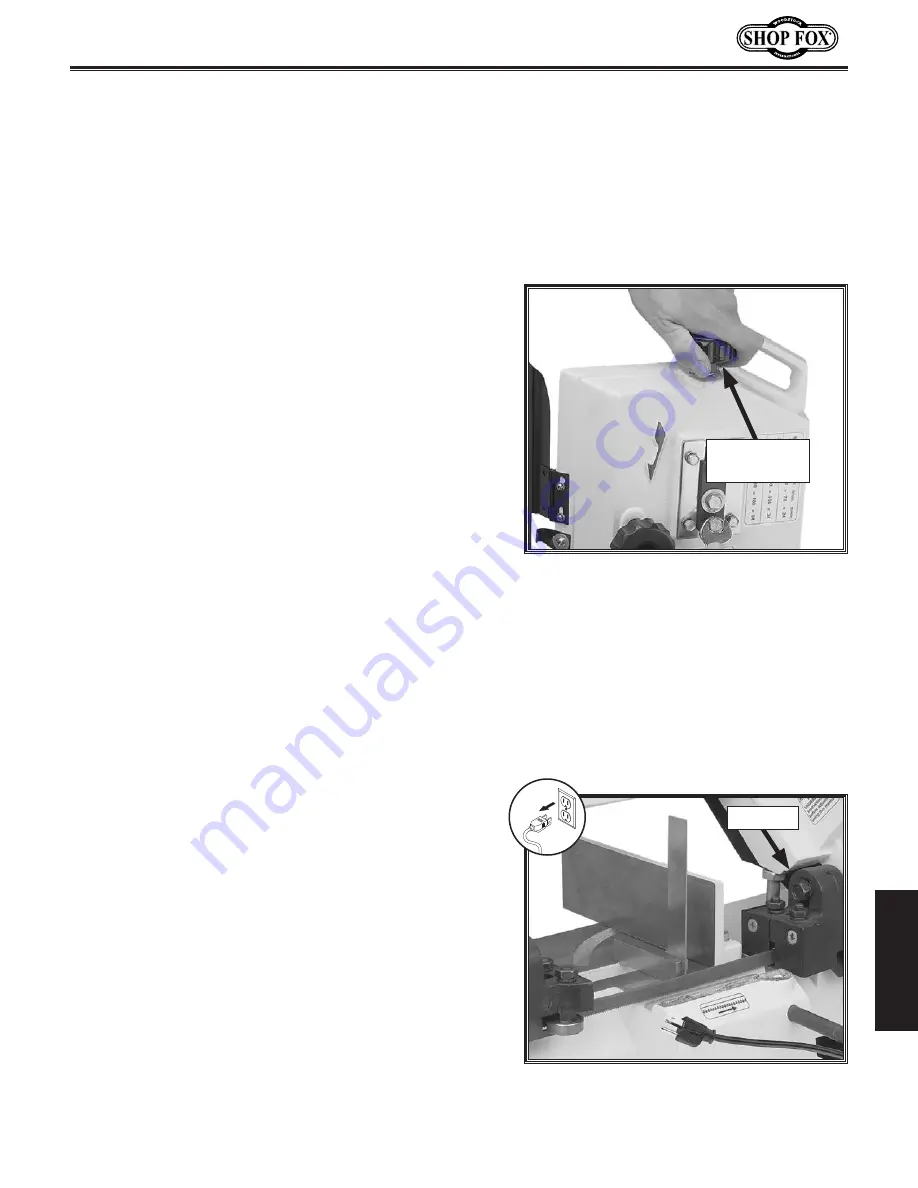

Turn the blade tension knob in

Figure.

46

clockwise

to tighten the blade as tight as you can.

5.

Using moderate finger pressure, push against the

side of the blade. The blade should not move more

than 0.004".

Squaring.Blade

It is always a good idea during the life of your saw

to check and adjust this setting. This adjustment will

improve your cutting results and extend the life of your

blade.

To.square.the.blade.to.the.bed.of.the.table,.do.these.

steps:

1.

DISCONNECT BANDSAW FROM POWER!

2.

Separate the blade guides as far as possible, the

lower the head of the bandsaw all the way until it

contacts the horizontal stop.

3.

Place a square on the table bed and against the edge

of the blade (

Figure.

47

), and check different points

along the length of the table between the blade

guides.

4.

Loosen the hex bolt shown in

Figure.

47

, and rotate

the seat until the blade is vertical to the bed, then

re-tighten the hex bolt.

Figure.

47

.

Squaring the blade.

Hex Bolt

Figure.

46

.

Blade tension knob.

Blade

Tension Knob

Summary of Contents for W1715

Page 45: ...Model W1715 For Machines Mfd Since 9 17 ...

Page 48: ......