-34-

Model W1715 (For Machines Mfd. Since 2/19)

SE

RV

IC

E

Blade.Guide.Bearings

The blade guide bearings must be properly adjusted to

make square cuts. One bearing on each assembly has an

eccentric bushing that allows it to be adjusted so the

blade is square to the vise. The bearings are secured

in place by a hex nut and lock washer, as shown in

Figure.

48

.

Before adjusting the blade guide bearings, make sure that

you have squared the blade to the table as discussed in

the previous section.

To.adjust.the.blade.guide.bearings,.do.these.steps:

1.

DISCONNECT BANDSAW FROM POWER!

2.

Position the vise to 90°, then lock it in place.

3.

Put a machinist's square against the face of the vise

and move it over to the blade.

— The square should evenly touch both the face of

the vise and the blade. If it does, skip ahead to

Step.6

.

— If the square does not evenly touch the blade, but

it does evenly touch the vise, continue with the

next step.

4.

Loosen the hex nuts that secure the eccentric

bushings attached to the guide bearings.

5.

Adjust the bearings as necessary to force the blade

to be 90° to the vise, then re-tighten the hex nuts.

6.

If any of the bearings are not touching the blade

evenly, loosen the hex nuts and adjust them so the

contact surface of the bearings touch the blade

evenly.

Note:

Since the bearings twist the blade into

position, it is acceptable if there is 0.001"-0.002"

gap between the blade and the front or back of

the bearing. Just make sure not to squeeze the

blade too tightly with the bearings. After the guide

bearings are set, you should be able to rotate the

guide bearings (although they will be stiff) with

your fingers.

7.

Adjust the backing bearing in the same manner, but

leave a gap between 0.002-0.003" from the back of

the blade.

Figure.

48

.

Blade guide adjustment

controls.

Backing Bearing

Hex

Nut

Eccentric Bushing

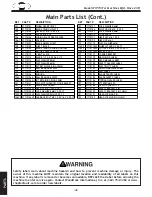

Summary of Contents for W1715

Page 45: ...Model W1715 For Machines Mfd Since 9 17 ...

Page 48: ......