-10-

Model W1754H (For Machines Mfd. Since 9/19)

O

PE

R

ATIO

NS

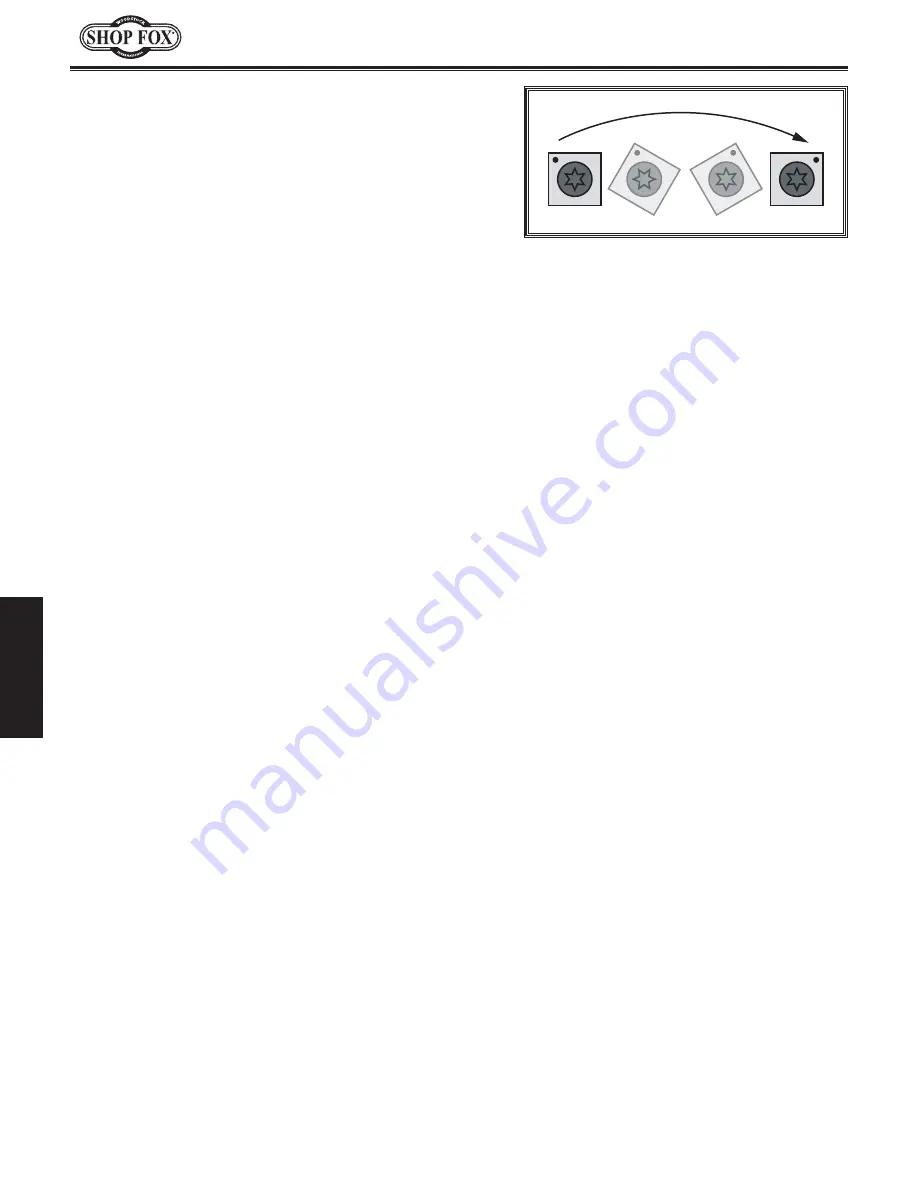

Figure 4.

Insert rotating sequence.

6.

Rotate insert 90° and install so that a fresh cutting

edge faces outward (see

Figure 4

).

— When all four insert cutting edges have been used,

replace insert with a new one. Always position

new insert reference dot in same position to aid in

rotational sequencing.

7.

Lubricate Torx screw threads with a very small

amount of light machine oil, wipe excess off, and

torque screw to 50–55 inch/pounds.

Note:

If too much oil is applied to the threads,

excess oil will attempt to squeeze out of the

threaded hole and raise insert during installation,

bringing it out of height alignment.

Summary of Contents for W1754H

Page 20: ......

Page 31: ... ...

Page 34: ... 3 W1754 20 Planer With Mobile Base INTRODUCTION ...

Page 70: ... 39 W1754 20 Planer With Mobile Base SERVICE W1754 Wiring Diagram ...

Page 73: ... 42 W1754 20 Planer With Mobile Base PARTS Headstock Assembly Parts Breakdown ...

Page 78: ... 47 W1754 20 Planer With Mobile Base PARTS Base Breakdown ...

Page 81: ... 50 W1754 20 Planer With Mobile Base PARTS Columns Breakdown ...

Page 85: ......

Page 88: ......

Page 89: ......