Model W1791/W1792 Mini HVLP Spray Gun

-10-

Cleaning

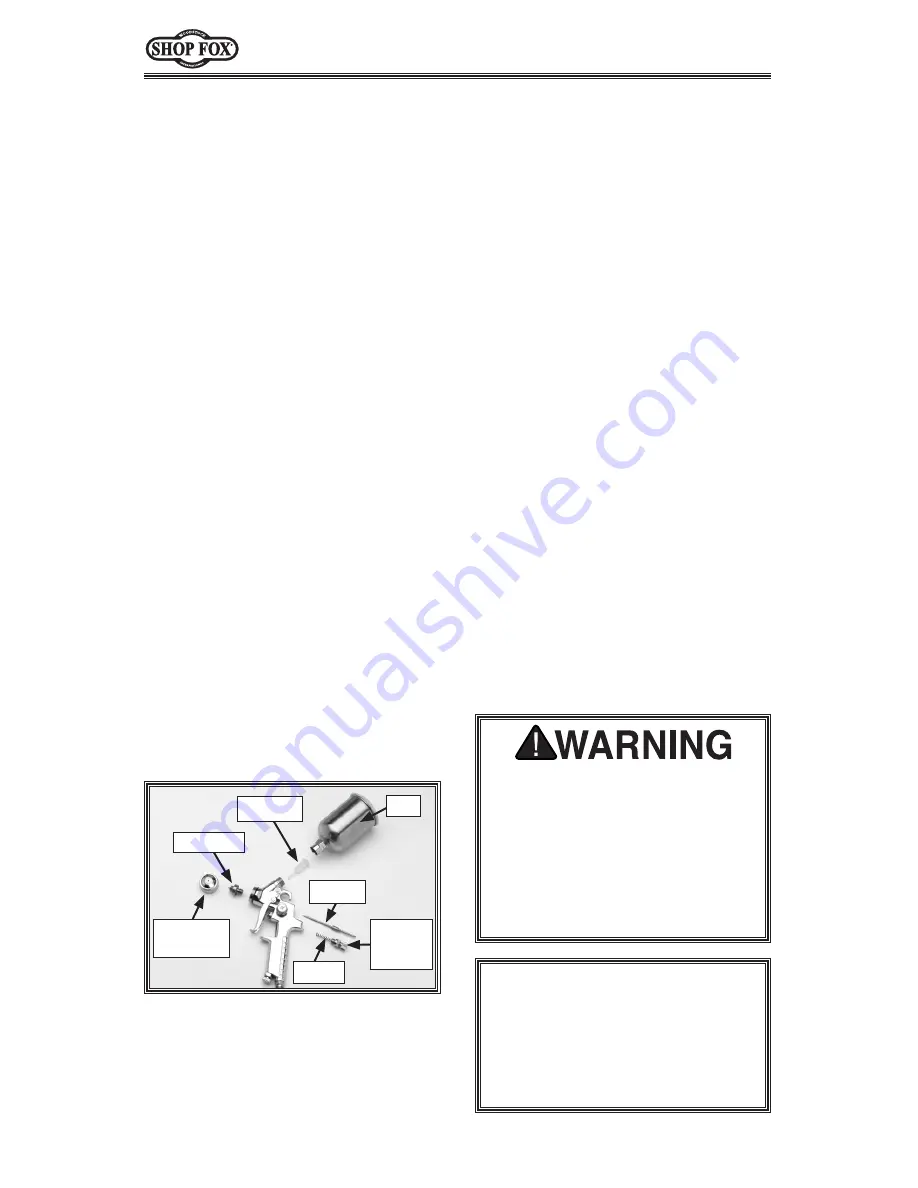

Figure 10.

Disassembly for cleaning.

Atomizing

Cap

Fluid Tip

Strainer

Spring

Cup

Fluid

Control

Knob

Needle

Proper cleaning is the best way to ensure

trouble free performance from your spray

gun. If your gun is not thoroughly cleaned,

damage and poor spraying will result.

Problems caused by improper cleaning will

not be covered by the warranty. Clean the

spray gun immediately after each use.

To clean your spray gun:

1.

Spray a small amount of solvent

through the spray gun.

Note:

Check with local laws

regarding this practice. If you are

spraying on a regular basis, spraying

solvents into the air may be illegal. A

cabinet style spray gun cleaner may

be required.

2.

DISCONNECT SPRAY GUN FROM AIR!

3.

Unscrew the cup.

4.

Disassemble the gun by unscrewing

the fluid control knob, removing the

spring and needle (

Figure 10

).

5.

Unscrew the atomizing cap with

your fingers and the fluid tip with

the service wrench. The fully

disassembled gun should look like

Figure 10

.

6.

Rinse these parts thoroughly in

solvent then dry with compressed air

or let air dry.

Note:

If the small holes in the

atomizing cap become blocked, soak

in clean solvent. If the blockage

still exists, clear the blockage with

a small needle, taking great care

to not enlarge or damage the hole.

Damage to the hole will create a

disrupted spray pattern.

7.

Use the cleaning brush with solvent

to clean the inner orifice and other

hard to reach areas on the outside of

the spray gun body.

8.

Wipe the rest of the gun body with a

shop towel and dry.

EXPLOSION HAZARD! Chlorinated

Solvents like Tricloroethane and

Methylene Chloride (methyl chloride)

can chemically react with aluminum

and may explode. Many parts in spray

guns are made of aluminum. Read

solvent label carefully before using

solvent.

NOTICE

DO NOT soak the spray gun body

in solvent. Prolonged exposure to

solvent will rapidly deteriorate the

spray gun washers and seals. Ignoring

this notice will void your warranty.

CLEANING & LUBRICATION

Summary of Contents for W1791

Page 2: ... ...