-22-

Model W1836 (For Machines Mfd. Since 04/15)

O

PE

R

ATIO

NS

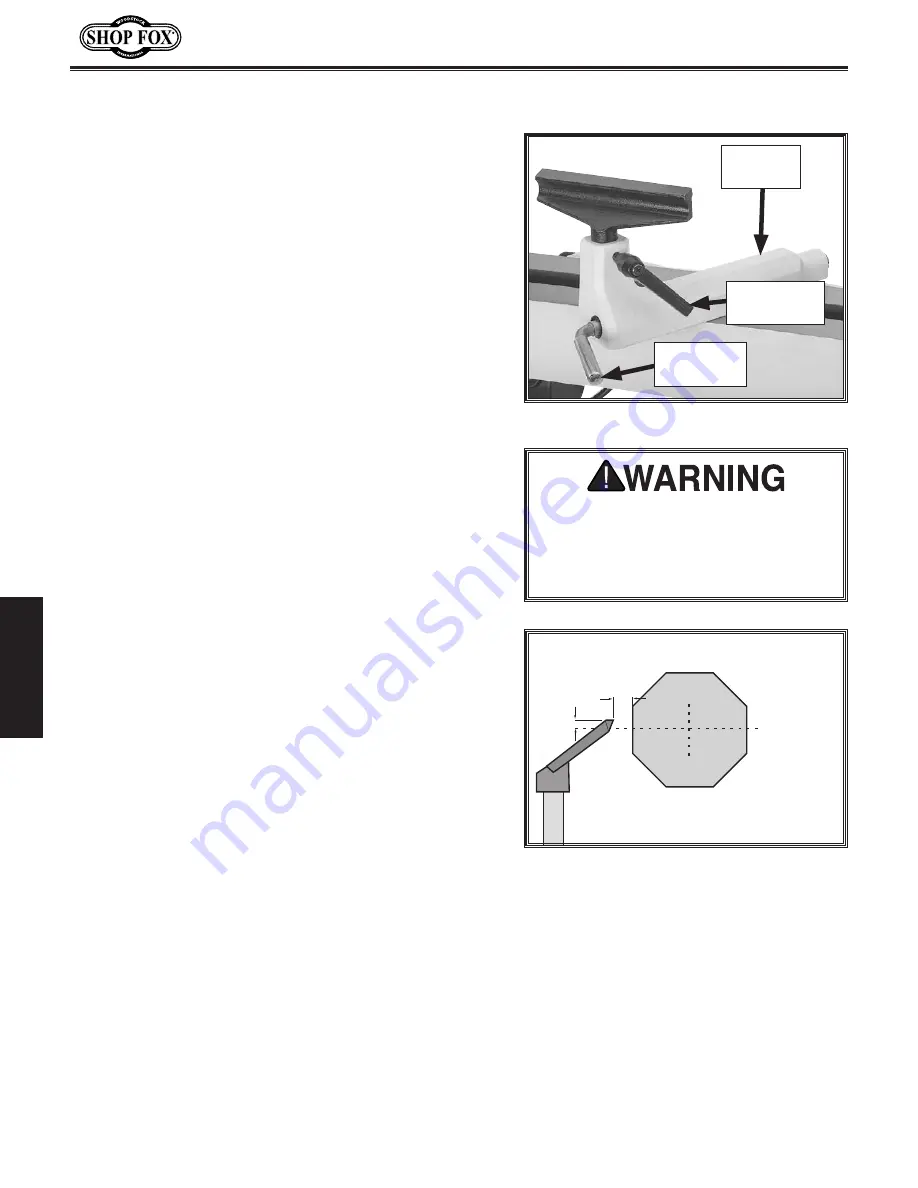

Adjusting.Tool.Rest

The tool rest is equipped with a cam-action clamping

system to secure it to the lathe bed. When the tool rest

lock lever is engaged, a locking plate lifts up and secures

the tool rest base to the bed.

Figure 19. Tool rest controls.

Workpiece

Center Line

Distances

Tool Rest

1

/

8

"

1

/

4

"

Figure

20

. Tool rest position relative to

workpiece.

Tool Rest

Lock Lever

Tool Rest

Lock Handle

Tool Rest

Base

1. Loosen tool rest lock lever and slide tool rest base

along bed (see

Figure 19).

2. Tighten tool rest lock lever to lock tool rest base in

place.

— If release lever will not lock tool rest base onto

bed (either too loose or too tight), then loosen or

tighten lock nut (located on underside of tool rest

base) in small increments as needed to achieve

proper clamping pressure.

Positioning.Along.Bed

1. Loosen tool rest base lock lever and tool rest lock

handle to adjust position of tool rest.

2. Position tool rest approximately

1

⁄

4

" away from

workpiece and approximately

1

⁄

8

" above workpiece

center line, as shown in

Figure 20.

3. Re-tighten tool rest lock handle and tool rest lock

lever to secure tool rest in position.

Adjusting.Angle.or.Height

Always operate lathe with tool rest

assembly firmly locked in position.

Otherwise, serious personal injury

may occur by tool being pulled from

operator's hands.