-24-

Model W1843 (For Machines Mfd. Since 3/17)

O

PE

R

ATIO

NS

To correctly tension the sanding belt, do these steps:

1. DISCONNECT MACHINE FROM POWER!

2. Make sure the sanding belt is correctly installed and

centered on the idler and drive wheels.

If sanding belt comes loose from

machine during operation, it could

cause serious personal injury from

entanglement or abrasion. ALWAYS

make sure sanding belt is properly

installed, tensioned, and tracked

before connecting machine to power.

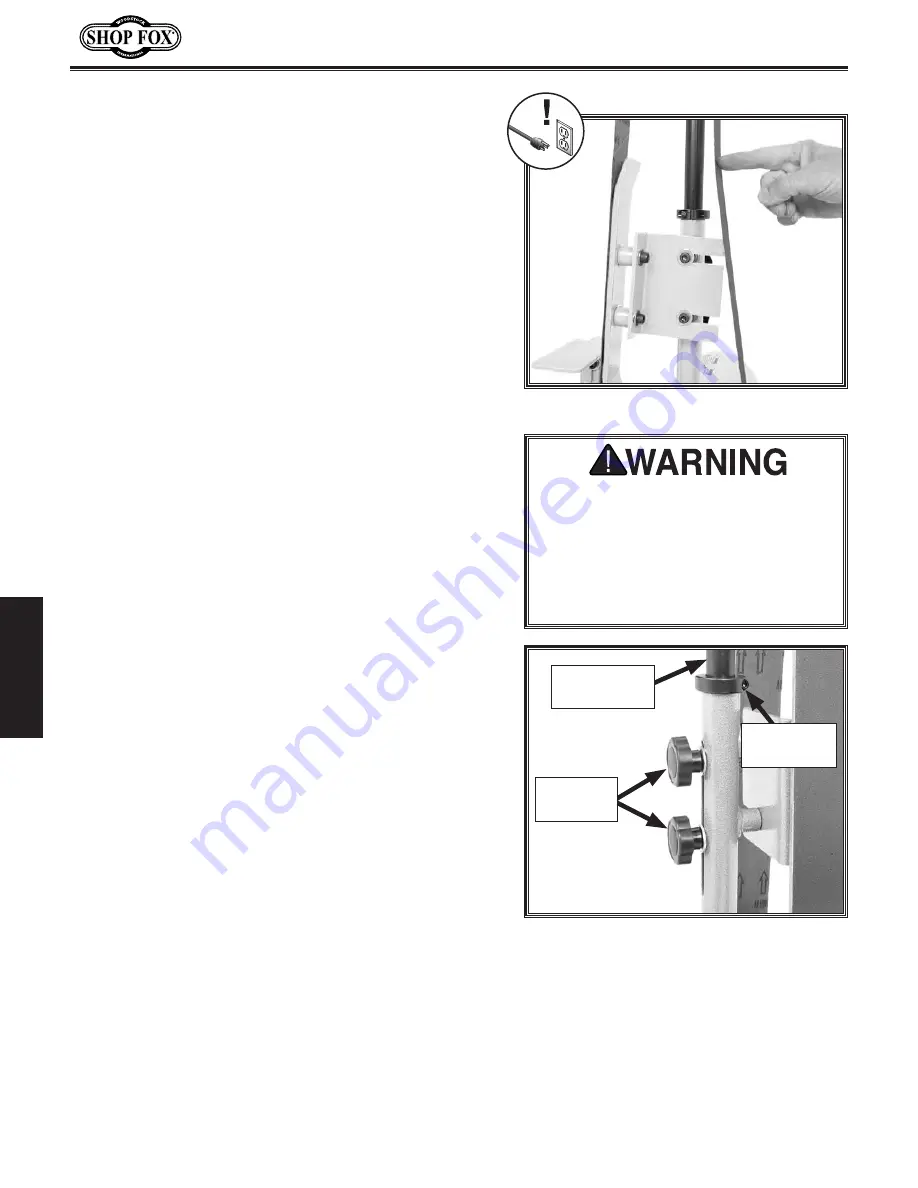

3. Hold onto the sanding arm assembly to keep it from

moving, then loosen the threaded knobs and the lock

collar cap screw shown in

Figure

21

.

4. Adjust the height of the sanding arm assembly

so there is the correct amount of tension on the

sanding belt, then re-tighten the threaded knobs to

hold the assembly in place.

5. Adjust the lock collar so that it is firmly seated on

the pivot arm top, then re-tighten its cap screw.

Note: The lock collar ensures the stability and

position of the sanding arm beyond the holding

power of the threaded knobs.

6. Re-check the sanding belt tension. If necessary,

repeat this procedure until the correct belt tension

is achieved.

Figure

21

. Sanding belt tension controls.

Lock Collar

Cap Screw

Threaded

Knobs

Sanding Arm

Assembly

Figure

20

. Checking sanding belt tension.

The sanding belt is properly tensioned when there is

approximately

1

⁄

2

" deflection with slight pressure applied

to the back loop of the belt, as shown in

Figure

20

.

The sanding belt tension is adjusted by raising or lowering

the sanding arm assembly.

Tool.Needed.

Qty

Hex Wrench

3

⁄

16

" ................................................1

Tensioning.Sanding.Belt