Automatic Tool Changer (ATC) Installation Manual

●

July 23, 2018

© Copyright 2018 ShopBot Tools, Inc.

page 26

Step 7: Get Plate Offset (CN73)

Note:

This file is included with ShopBot Versions 3.8.28 and later. Users of earlier version can add it by

contacting ShopBot technical support.

This routine will establish where the C3 (XYZ zero) routine will set the Z zero level. Normally this is at the

table bed. This routine needs to be run whenever the location of the table bed has changed, such as after

re-surfacing the spoilboard. If a tool is not loaded in the spindle, select one before running this routine. Any

tool can be used as they have all been zeroed to the fixed plate. Type “CN73” (custom number 73) in the

ShopBot control software to run the ATC get plate offset file.

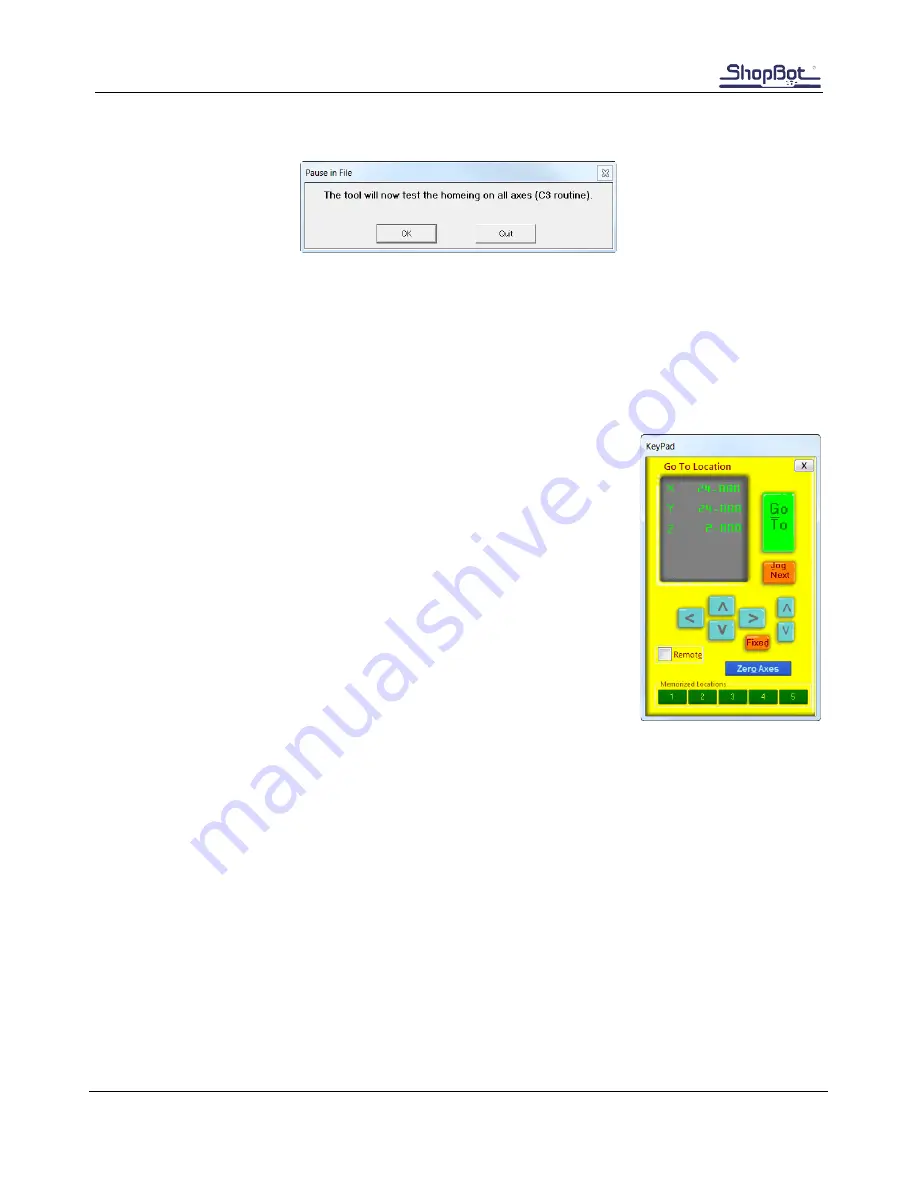

Use the keypad to move to the location where the Z level is located. If zeroing

to a specific fixture, move the tool over it. Close the keypad when the tool is at

the desired position.

Place the grounding clip on the collet or bit and place the regular Z zero plate below the bit (this routine

does not use the fixed Z zero plate). Click “OK”, and the routine will touch off the zero plate and save the

offset from the fixed Z zero plate. When the plate is removed, the tool will confirm the proximity switch

locations and new Z zero level.

Every time the C3 routine is run the tool will be zeroed at this stored level.

NOTE: Pay attention to where Z zero is set in the CAM file to avoid damaging the table surface or

cutting the wrong depth.