Operating Instructions:

Following is a brief description of the various switches and dials:

1.

POWER:

Flip POWER switch ON to energize control box.

Red POWER light will illuminate. The unit requires 5 seconds to

initialize. Avoid pressing any control buttons while unit initializes.

2.

MANUAL:

Operate control box left, right, and change speeds.

3.

LOGIC:

Switch reverses the direction that the cow or flag

travels.

Example:

After the Pro Cutter is installed, attach remote control to

your wrist (wrist watch position) and button assembly on index

finger. Press left switch with your thumb. If cow or flag travels to

left, you’re ready to go. However, if cow or flag travels right

toggle LOGIC switch. This will cause the cow or flag to travel left

as you press left switch – and right as you press right switch.

4.

FUSE:

Power surges, faulty cord, or defective component may

cause a fuse to blow. When this happens, remove fuse and replace

using only 4 amp/250v AGC fuse, or permanent damage may

result.

NOTE: power indicator light will not illuminate when fuse is bad.

5.

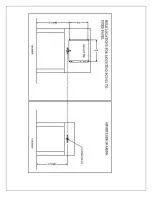

SPEED DIALS: Front face of control box

SPEED 1:

The left speed dial is the starting speed. When the

control box is asked to run using either remote or manual

control switches, the cow or flag will begin moving at Speed 1

regardless of direction. To stop, simply release button or

switch.

SPEED 2:

The right speed dial is second speed. To access

Speed 2, begin by pressing a run button on remote or manual

control. The cow or flag will begin moving at Speed 1. When

traveling at Speed 1, release button and re-press immediately.

Control box will shift to Speed 2.

EXAMPLE:

Set Speed 1 (left dial) to "15", and Speed 2 to

"45". When a run button is pressed, the cow or flag will move

at SPEED 1. To shift to SPEED 2, start the cow moving at