11

Order code: 75132

Multigrip Clamp

Maintenance

The operator has to make sure that safety-related and machine-technical installations are to be

inspected by an expert after every year in the course of an acceptance test.

The operator has to make sure that safety-related and machine-technical installations are to be

inspected by a skilled person once a year and more frequently if used intensively.

The following points have to be considered during the inspection:

01)

All screws used for installing the device or parts of the device have to be tightly connected and

must not be corroded.

02)

There may not be any deformations on housings, fixations and installation spots.

03)

Mechanically moving parts like axles, eyes and others may not show any traces of wearing.

The Multigrip Clamp requires almost no maintenance. However, you should keep the clamp clean. Wipe

with a damp cloth. Do not immerse in liquid. Do not use alcohol or solvents.

●

All inspections and any actions taken, must be documented in writing.

●

After using the clamp, any dirt needs to be removed.

●

Always store the clamp in a dry environment, to prevent corrosion.

●

Repairs may only be carried out by experts that are authorized in writing by Highlite International.

●

In case that repairs or modifications are carried out by unauthorized personnel, the warranty and

product liability will become void. Only use original parts for repairs.

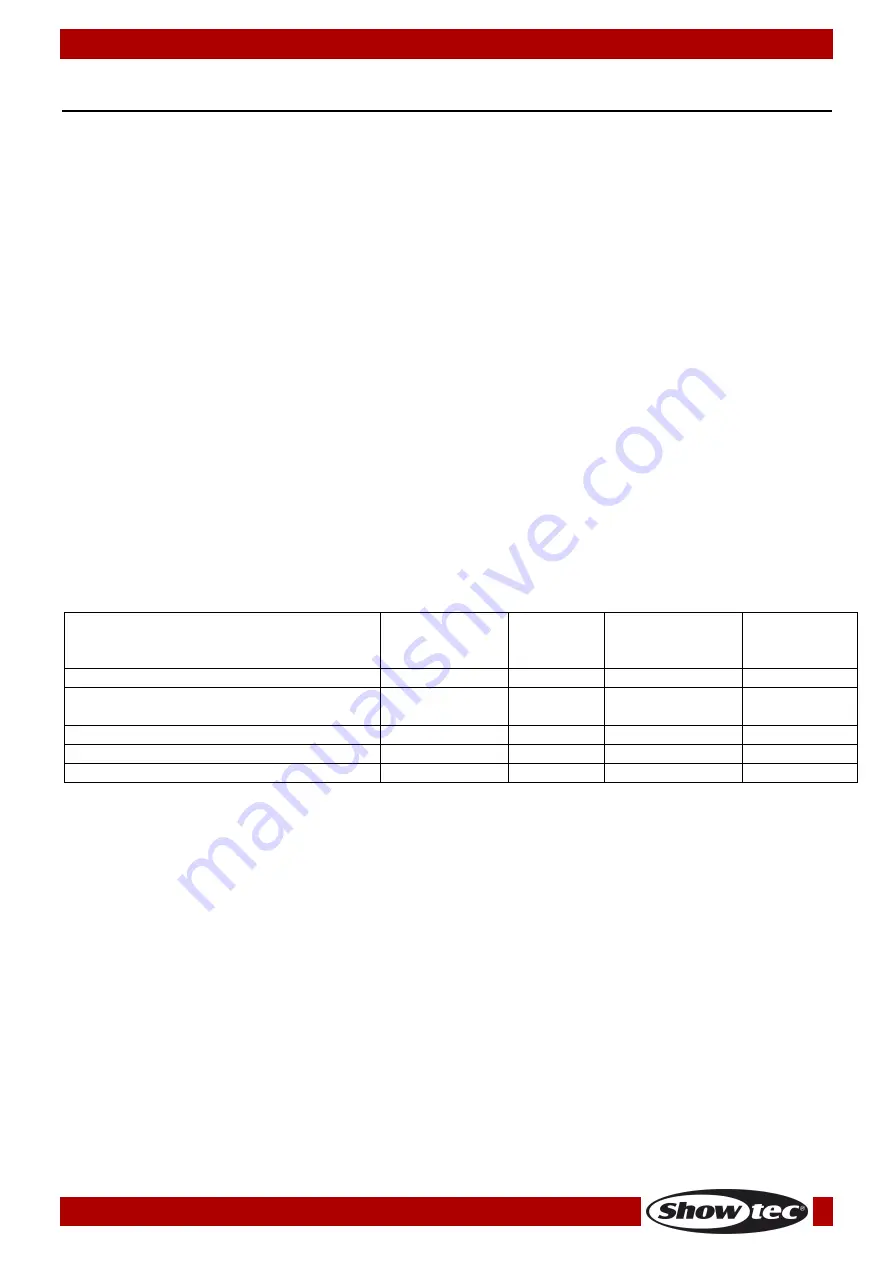

Inspection & Maintenance Intervals

The following inspection and maintenance intervals apply for normal use. In case of use in harsh

environment, such as regular deployment at full load or use in a hot / dusty or otherwise aggressive

environment, the indicated intervals should be shortened.

When

commissioning

Daily

inspection

1

st

maintenance

after 3 months

Inspection /

maintenance

annually

Check screw / bolt connections

X

X

X

X

Check spindle mechanism for proper

functioning

X

X

X

X

Check for any deformations

X

X

X

X

Check and lubricate spindle mechanism

X

Regular inspection by an expert

X

Regular Inspections

Regardless of national rules in the country of use, the Multigrip Clamp has to be inspected by an expert,

at least once a year.

●

In case of heavy/frequent usage, the inspection and maintenance intervals need to be more

regular.

●

Check the Multigrip Clamp carefully, to make sure that there are no unusual noises that could

indicate faults or excessive wear.

●

Make sure all bolts and nuts are tight and check presence and legibility of the type plate.

Summary of Contents for 75132

Page 14: ...13 Order code 75132 Multigrip Clamp Notes ...

Page 15: ...14 Order code 75132 Multigrip Clamp ...

Page 16: ... 2020 Showtec ...