Summary of Contents for SA 400 minifloppy

Page 1: ...SA400 W minifloppyTM Dis ette StorageDrive D 2 I I shUgart Associates ...

Page 2: ...SA400 rt J minifloppyTM Disl etteStorageDrive D 2 2 2 I I Copyright 1977 Shugart Associates ...

Page 4: ...Section 1 ...

Page 28: ......

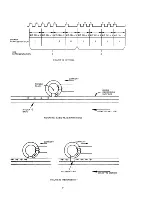

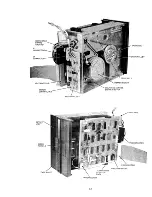

Page 41: ...Physical Locations 11 ...

Page 42: ...P4 HEAD CABLE CONNECTOR CLAMP HUB 12 HEAD CABLE EXTENDER ...

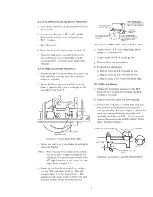

Page 44: ......

Page 45: ...PCB Component locations 15 ...

Page 50: ......

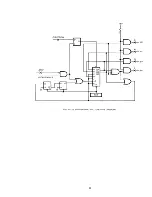

Page 51: ...LogicManual 21 ...

Page 56: ......

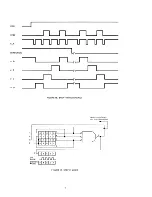

Page 57: ...SCherTlotics 26 ...

Page 58: ......

Page 67: ...Section 3 ...

Page 68: ...Table f Contents Description Drive Assembly Numeric Index 1 3 4 ...

Page 70: ... ...

Page 73: ...22 16 60 ...