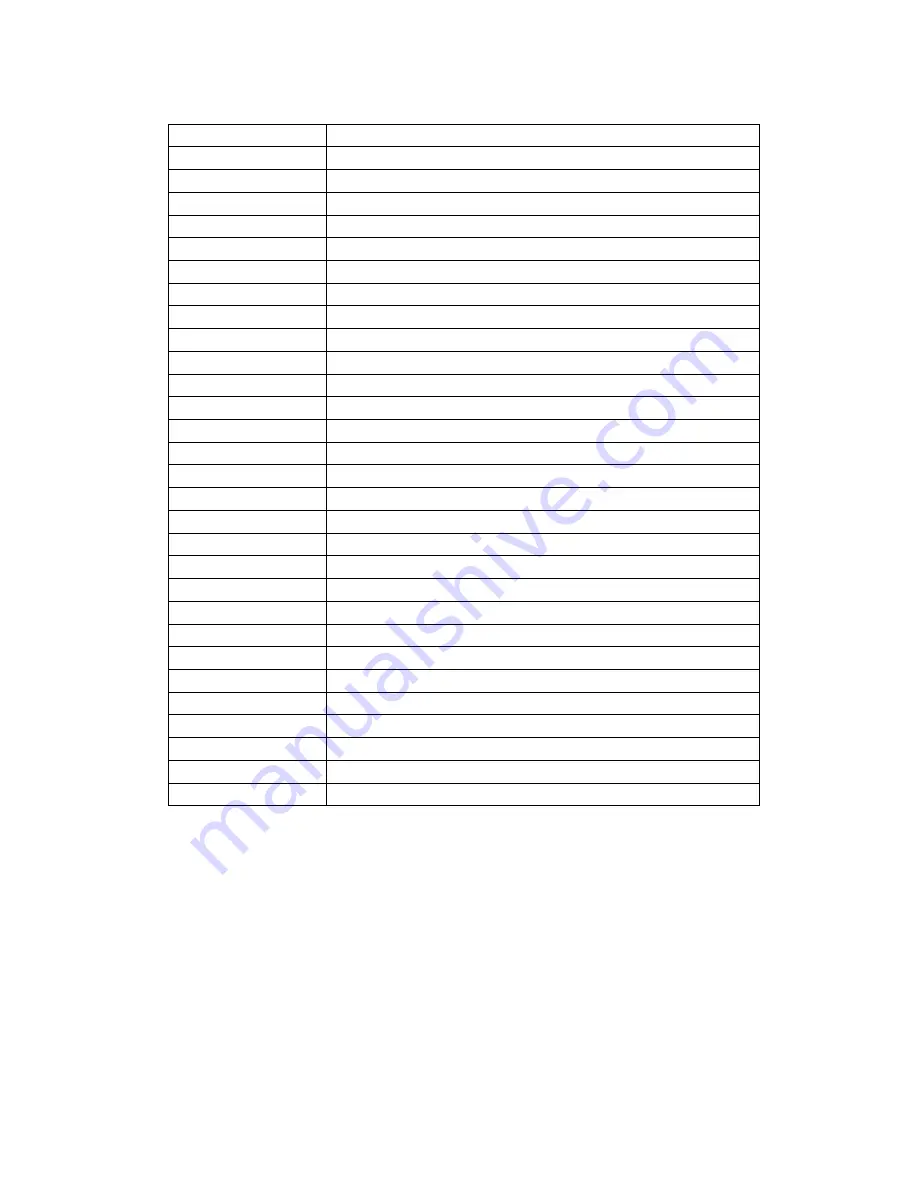

SL-300E Automatic Meat Slicer Parts List

No.

Names of component parts

61

Blade

Φ

300

62

Blade guard ring

63

Square nut of protection plate

64

Pulley axle

65

Belt pulley of the blade

66

Belt TB2-420A

67

Bearing 6204

68

Big retainer ring

69

Small retainer ring

70

Guard ring bolt

71

Guide strip

72

Tension rod of protection plate

73

Adjusting knob

74

Sharpener support

75

Adjusting screw

76

Supporting shoe

77

Support bracket bolt

78

Small grinding wheel

Φ

50

79

Upper button of the sharpener pin

80

Thick

grinding wheel

Φ

47

81

Grinding wheel pin

82

Sharpener cover

83

Sharpener knob

84

Sharpener support pin

85

Sharpener components seat

86

Grinding wheel pin

87

Upper button of the sharpener pin

88

Power cord

89

Worm-wheel shaft

Summary of Contents for SL-300E

Page 1: ... 封面 SL 300E Automatic Meat Slicer Instruction ...

Page 8: ......