Installation, Use and Maintenance Manual - CFR micro / CFR micro E Series

page 23

INTRODUCTION

The CFR micro E heat recovery units feature compact dimensions and easy assembly.

The CFR micro E heat recovery units combine maximum room comfort with certain energy savings.

Current air-conditioning and air handling systems require forced ventilation, which consequently involves the discharge of the conditioned air and as

a result means significant energy consumption and an increase in running costs.

The CFR micro E series has been designed to resolve these probles by the use of static exchangers.

The CFR micro E series adopts an heat recovery made of plane sheets of special paper. These exchangers are also called tatal heat recoveries: infact,

they can recover both sensible and latent heat (humidity), with temperature efficiency between 60-80% and enthalpy efficiency tbetween 50-70%.

Thanks to this high efficiency, the fresh air in winter conditions can be directly introduced in air-conditioned rooms, without installing post-heating sec-

tions.

The drain pan collector is not present because the humidity contained in one of air flows is partially absorbed by the porous surface but then

completely transferred to the opposite flow: therefore the humidity condensation is avoided.

The high static pressure values available allow the use of ducting for the extraction or distribution of air in a series of rooms.

SECTION 1 - GENERAL CHARACTERISTICS

1.1 Presentation of the manual

This manual describes the rules for the transportation, the installation, the use and the maintenance of the heat recovery. The user will find every-

thing that is normally useful to know for a correct and safe installation of the CFR micro E unit.

The non-observance of what is described in this handbook and an inadequate installation of the CFR micro E unit may cause the cancellation of

the guarantee that the SIC srl Company grants on the same one. The SIC srl Company, moreover, does not answer to possible direct and/or

indirect damages due to wrong installation carried out by inexpert and/or non-authorised staff. At the moment of the purchase, check that the

machine is integral and complete. Claims will have to be produced within 8 days from the reception of the goods.

1.2 General characteristics

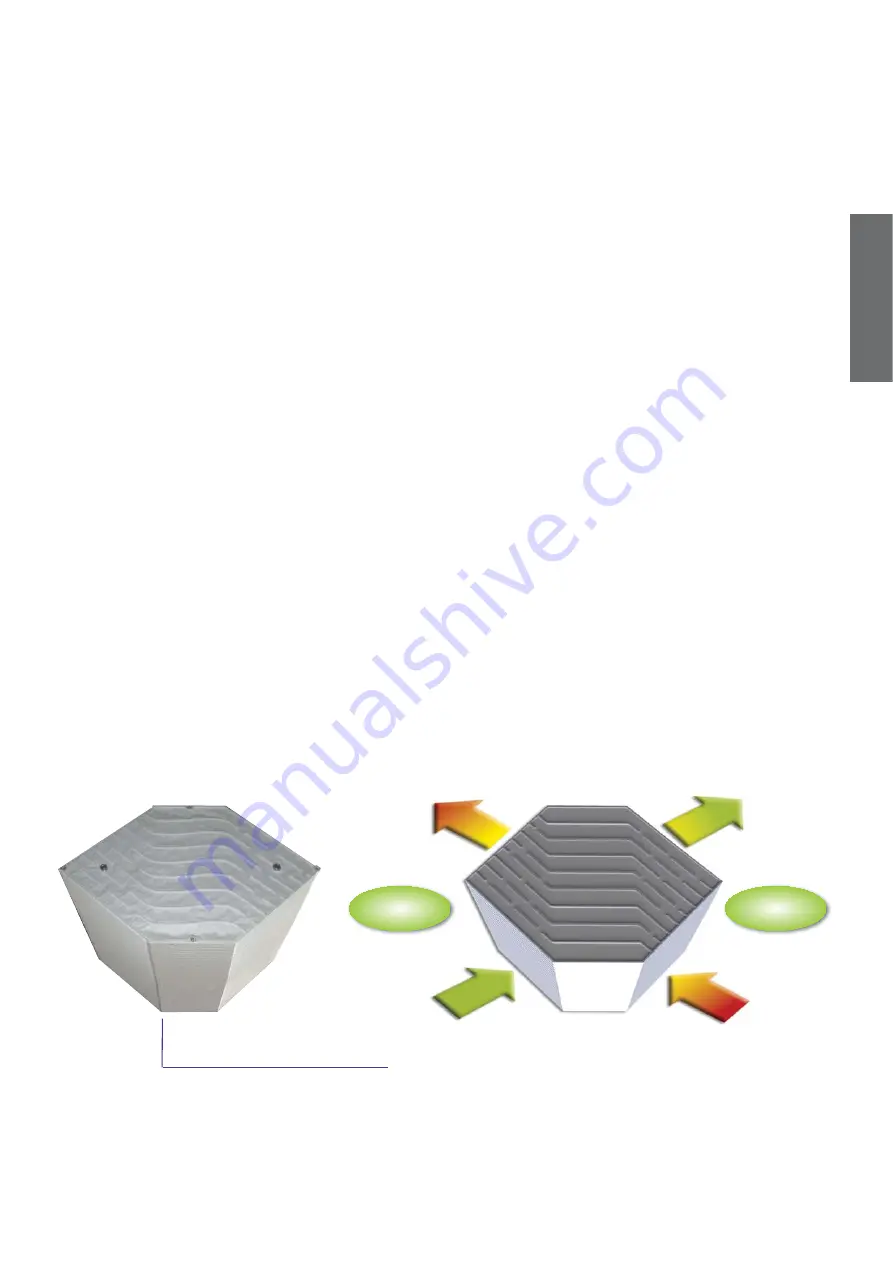

• Static, counterflow heat exchanger, made of plane sheets of special paper. These exchangers are also called “total heat exchangers”:

infact, they can recover both sensible and latent heat, with temperature efficiency up to 77% and enthalpy efficiency up to 63% and the-

refore they are particularly suitable for summer recuperation.

The air flows are separated by proper seal.

• Thanks to the accuracy of engineering, the units are very compact, and the periodical maintenance is very easy for the heat exchanger and

the filters, both removable from the side.

• Very noiseless running, thanks to high quality of materials and components.

• It is possible to by-pass the heat exchanger: so we can realize a “free-cooling” condition, useful during the between season.

• High efficient air filtration

• The fans feature

“brushless DC”

motors which allow to obtain higher efficiency than the standard motors

• Automatic free-cooling function

• LCD unit control panel (available as optional) featuring the on/off function, speed switching. It is suitable for wall mounting, in electric boxes

type “502” (2 modules).

The LCD control panel is suitable for infrared remote control (optional).

Counterflow enthalpic heat exchanger

Exhaust air

Fresh air

Fresh air

Exhaust air

OUTDOORS

INDOORS

page 23

Installation, Use and Maintenance Manual - CFR micro E Series

English