30

ENGLISH • Instructions manual

M 39 ATV

M 39 ATV

BEAD BREAKING

ATTENTION

During this stage of operation, noise levels may be up to 70 dB(A). We

recommend that operators wear hearing protectors.

Deciding from which side of the wheels the tyre

must be demounted

Clamp the rim on the turntable keeping the side of the rim on which the

brake disk or drum

is fitted facing downward.

Special instructions

Alloy wheels

Some alloy wheels on the market have minimal rim channels or are even

completely without rim channels (these wheels are not DOT approved).

DANGER

When working on these wheels, it is possible to damage the tyre, the

rim or both, with the risk of the tyre exploding under pressure causing

serious injury or death.

When mounting tyres on this type of wheel, use the utmost caution.

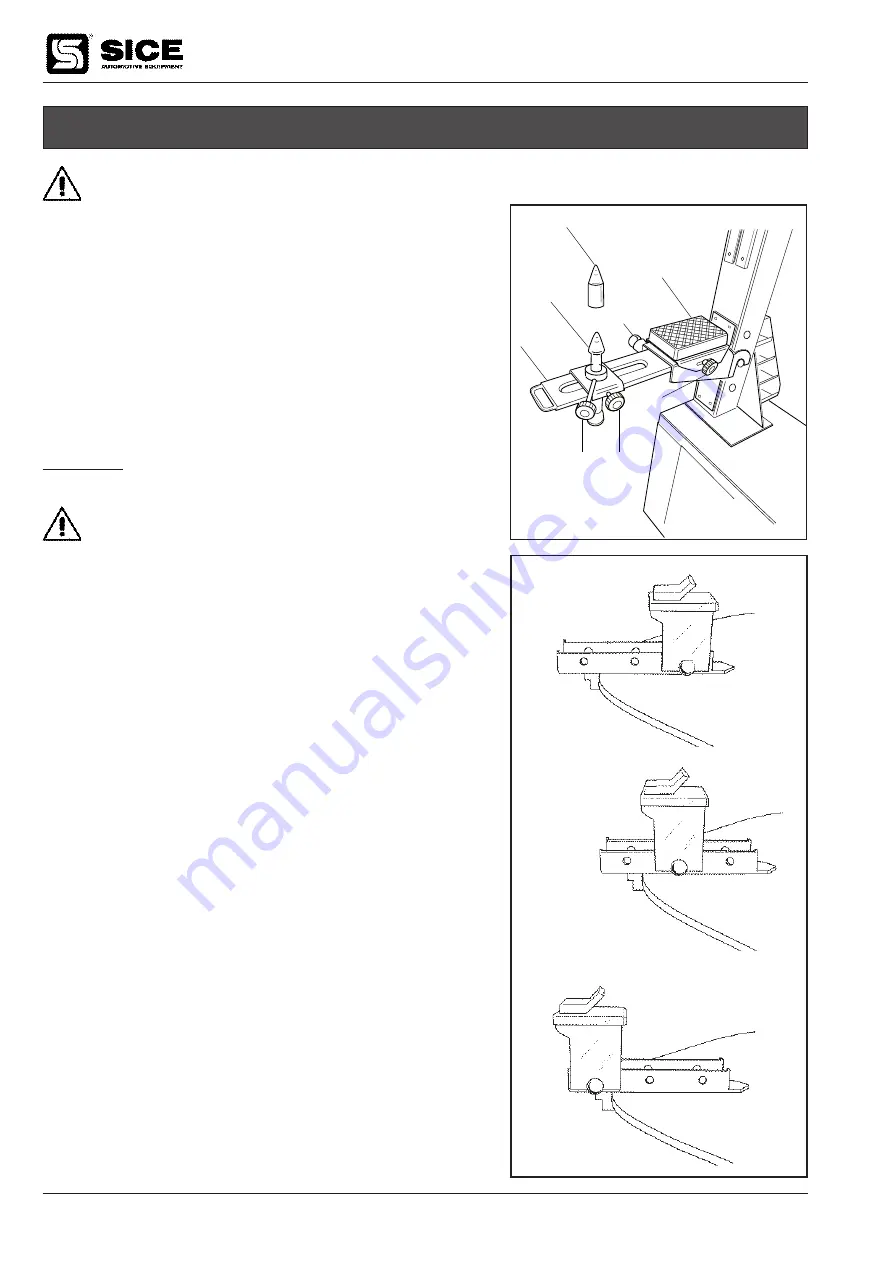

Bead breaking

- Fully deflate the tyre

- Depending on the wheel width to be handled, move the bead breaking support

to increase or decrease the machine bead breaking capacity (see Technical Data

paragraph).

- Place the wheel in the bead breaking position on the wheel support

Q

(Fig

5). With Kit SR line up the vertical slide arm

B

fig 4 with the central hole

of the rim, place the wheel in a perfectly horizontal position and tighten

the knob

F

fig 4.

- Pressing slightly on the bead breaker pedal

K

fig 5, position the bead

breaker on the bead of the tyre (Fig .6) The bead breaker pedal can be

removed to work more easily on larger diameter wheels

- Adjust the wheel position so that the bead breaker is as near as possible

to the edge of the rim and then tighten the knob

F

fig 4 and

D

fig 4.(Kit

SR optional)

- Press down the pedal completely to release the bead from the rim.

- Repeat this operation in various points around the tyre until the bead is

freed from the rim. Repeat the operation on the opposite side of the tyre.

If the wheel only has one kingpin with the hub to one side, use the hori

-

zontal swing arm extension

A

fig.4 so that the wheel is perfectly horizontal.

- Remove counterweights.

- Using pedal

G

, adjust the opening of the four self-centering clamps.

- Adjust the position of the sliding clamps (position 1,2 or 3) according to

the diameter of the wheel.(Fig 7).

- If the wheel that needs to be blocked has a diameter equal to 5’’ (go-kart),

the special plastic adaptors that are supplied with the machine must be

mounted.

- Lubricate the tyre all around the edge of the bottom and top bead to aid

A

B

C

D

E

F

G

H

4

5 - 13”

10 - 18”

15 - 23”

7

Summary of Contents for M 39 ATV

Page 19: ...ITALIANO Manuale d uso 19 M 39 ATV 12 12...

Page 37: ...ENGLISH Instructions manual 37 M 39 ATV 12 12...

Page 55: ...FRAN AIS Manuel d instructions 55 M 39 ATV 12 12...

Page 73: ...DEUTSCH Betriebsanleitung 73 M 39 ATV 12 12...

Page 91: ...ESPANOL Manual de instrucciones 91 M 39 ATV 12 12...