12. INTERNAL AND EXTERNAL SENSOR

(MECHANICAL MEASURING SENSOR OR ULTRASONIC SENSOR)

To view the sensor signals access the service environment;

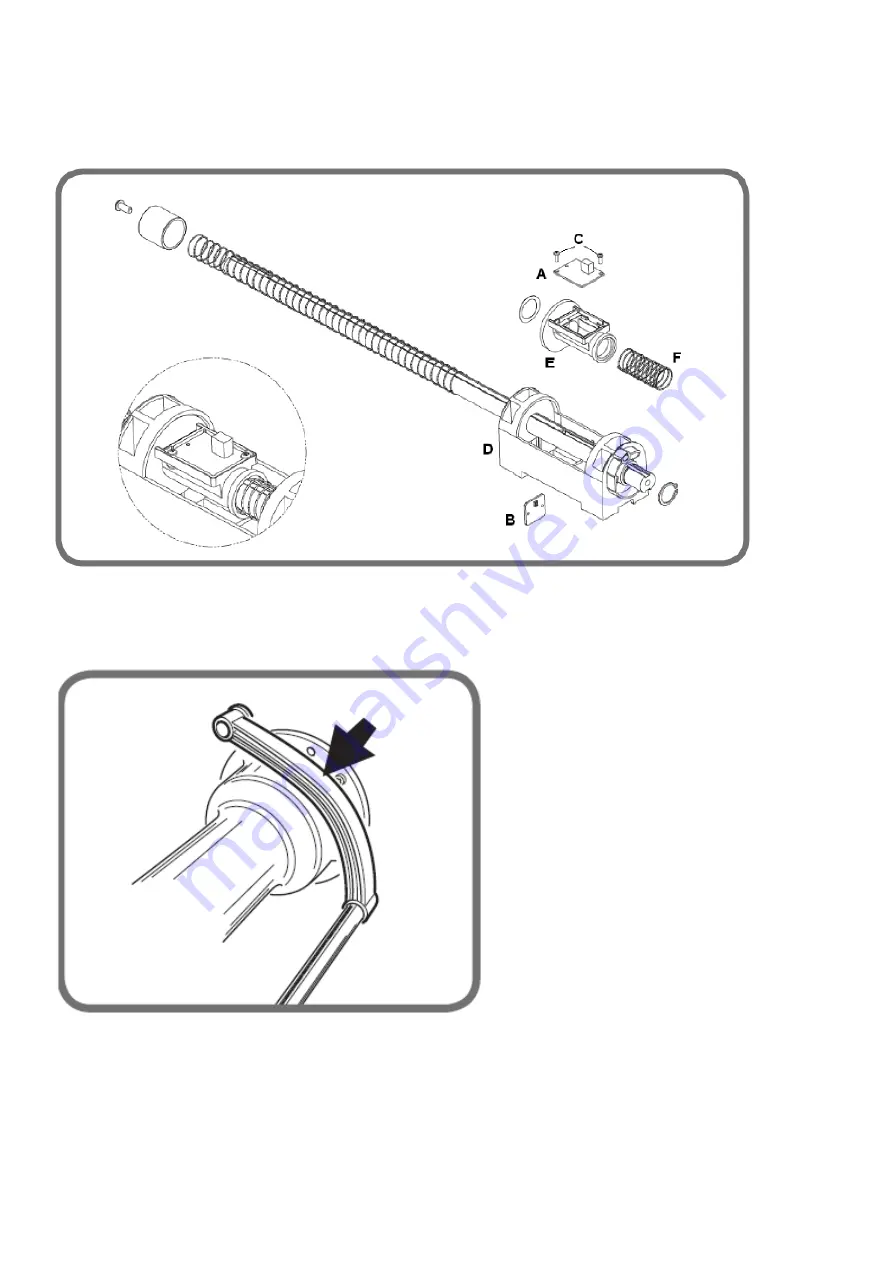

Fig. 6

12.1 Diameter sensor

Check that the stroke is made up of -110 notches with the lever resting on the bell of the swinging unit see Fig. 7 (maximum error a/- 5

notches in the position indicated).

Fig. 7

If the sensor (B, fig.6) does not read, check:

- the connection flat (L, fig 5);

- that the sensor is correctly assembled in its housing.

If these checks do not rectify the problem, replace the sensor

(B, fig.6) as follows:

- remove the weight tray

- remove the sensor lever;

- disassemble the measuring sensor support (D, Fig. 6), using the 4 fixing screws, from the internal plane;

Summary of Contents for S 64E

Page 43: ...Fig 20 fig 21...

Page 45: ......

Page 46: ...SECOND VERSION OF PNEUMATIC SYSTEM from April 2016...

Page 47: ...THIRD VERSION OF PNEUMATIC SYSTEM from March 2017...

Page 48: ...FOURTH VERSION OF PNEUMATIC SYSTEM...

Page 50: ...PEAL 32F...

Page 51: ......

Page 52: ...MBUGRF 2 LIGHT...

Page 53: ......

Page 54: ...COMIM Cod 4 119446B_EN 05 2018...