This function allows you:

to check with the maximum precision (a tenth of an inch) the match between the values obtained with the sensor and the nominal values of the

wheels.

- The current value of the angular position transducer of the wheel (encoder), its variation interval, and two numerical values corresponding to

the number of impulses counted by the encoder during a spin and the expected value for this count (XXX).

These data allow to:

to easily check the efficiency of the encoder. In particular, that the value of the encoder is continuously updated within the interval 0 - 511

when turning the shaft manually in the two directions, and that the two numerical values visualised on the right of the line are the same at the

end of a spin made in the service environment.

If the two numerical values displayed on the right side of the row are NOT equal, the encoder card must be replaced:

- switch off the machine;

- remove the weight tray;

- remove the card by unscrewing the two fixing screws, then fasten the new encoder card as follows:

a.

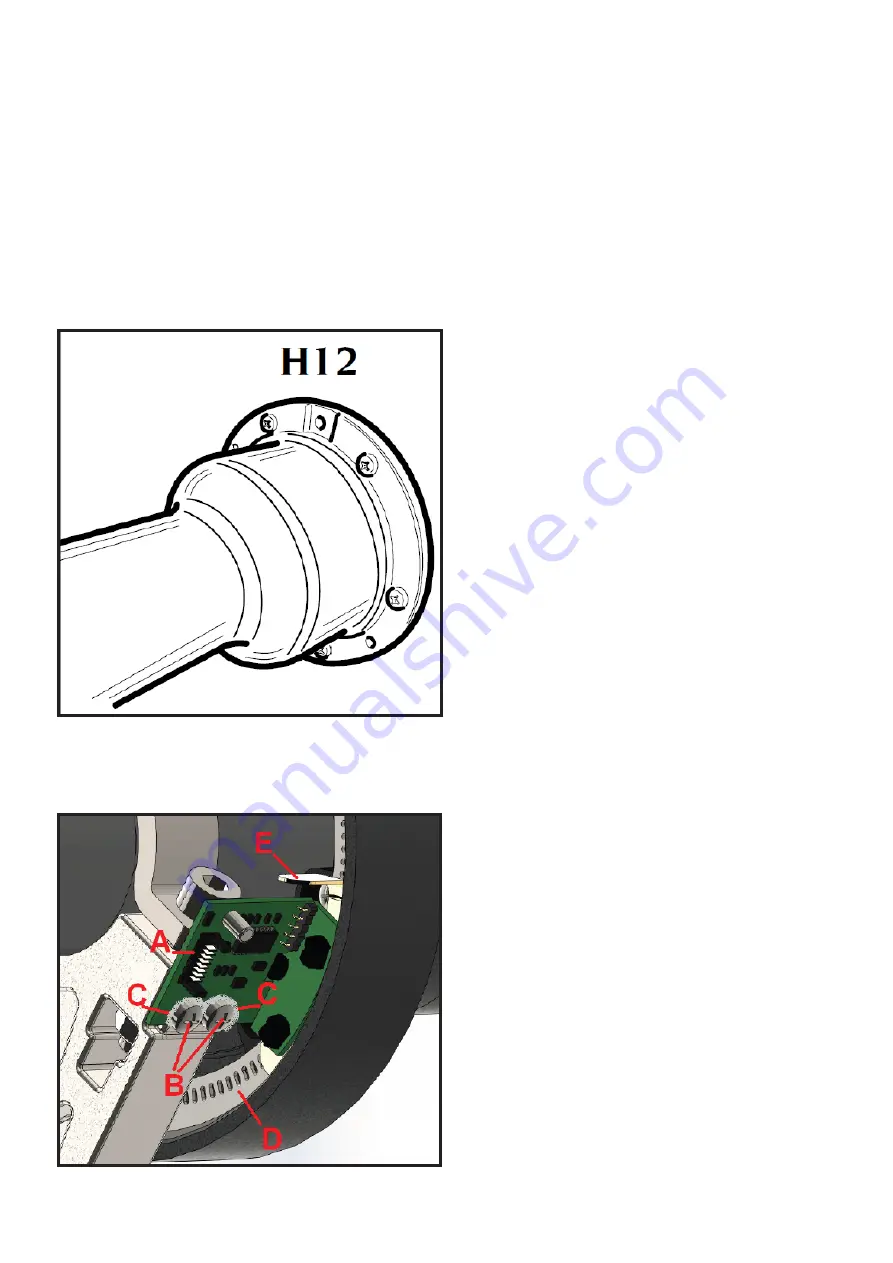

turn the shaft assembly until the threaded hole in the bell (used for fastening the calibration weight for sensitivity calibration), is positioned at H12 (see

Fig.2).

Fig. 2

b. fasten the search card (A, Fig.2a), so that its base rests on the step on the motor support, using the two screws (B, Fig.2a) and the fastening plate (C, Fig.2a)

provided (tighten the screws in a way that the card can be adjusted), then place the calibration template code 4-130557 (E, Fig.2a) between the card and the

metal disc (D, Fig.2a);

Fig.2a

Summary of Contents for S 64E

Page 43: ...Fig 20 fig 21...

Page 45: ......

Page 46: ...SECOND VERSION OF PNEUMATIC SYSTEM from April 2016...

Page 47: ...THIRD VERSION OF PNEUMATIC SYSTEM from March 2017...

Page 48: ...FOURTH VERSION OF PNEUMATIC SYSTEM...

Page 50: ...PEAL 32F...

Page 51: ......

Page 52: ...MBUGRF 2 LIGHT...

Page 53: ......

Page 54: ...COMIM Cod 4 119446B_EN 05 2018...