9

Maintenance

9.1

Maintenance

During operation, the device works maintenance-free.

Depending on the assignment location, the following preventive maintenance tasks

may be required for the device at regular intervals:

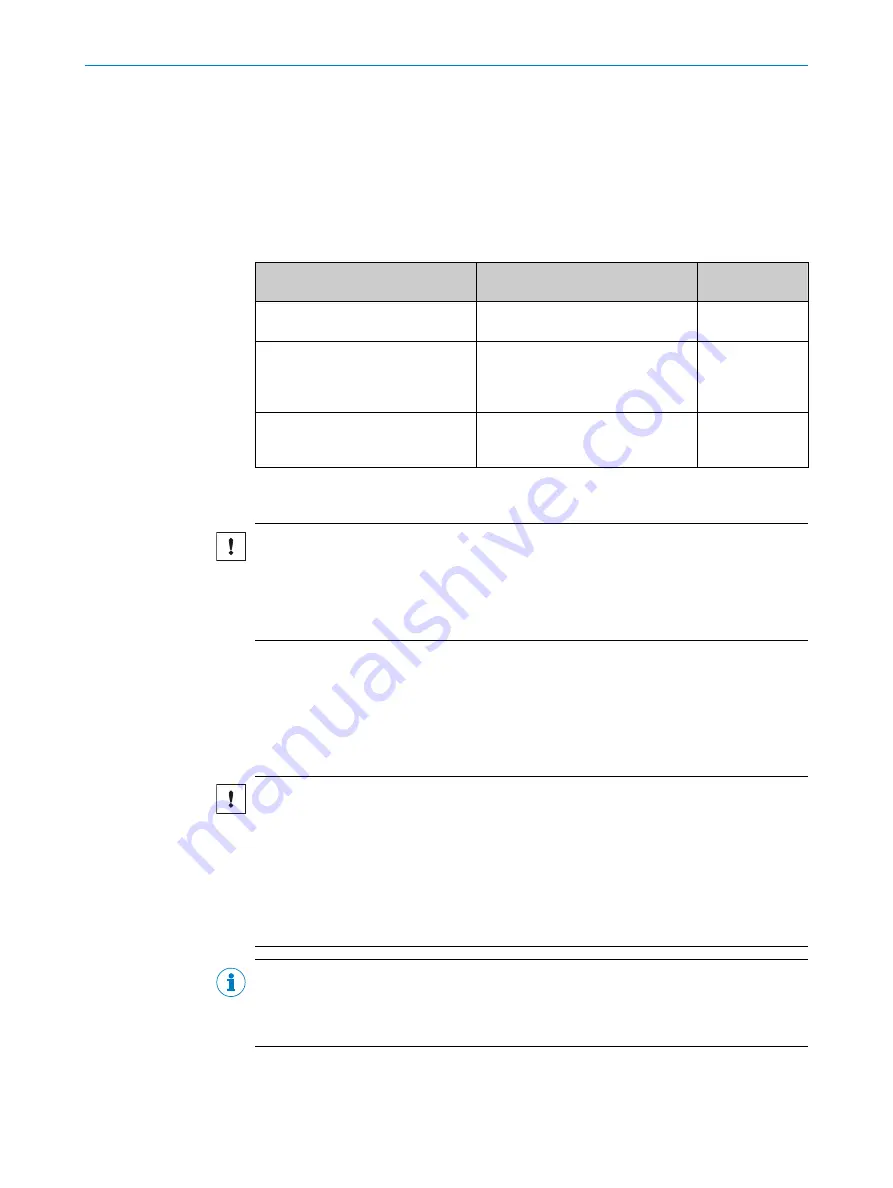

Table 12: Maintenance schedule

Maintenance work

Interval

To be carried out

by

Clean housing and front screen

Cleaning interval depends on ambi‐

ent conditions and climate.

Specialist

Check screw connections and plug

connectors

Interval depends on the place of use,

ambient conditions, or operational

regulations. Recommended: At least

every 6 months.

Specialist

Check that the unused connections

are sealed with protective caps or

plugs

Interval depends on ambient condi‐

tions and climate. Recommended: At

least every 6 months.

Specialist

9.2

Cleaning

NOTICE

Equipment damage due to improper cleaning.

Improper cleaning may result in equipment damage.

■

Only use recommended cleaning agents.

■

Never use sharp objects for cleaning.

Cleaning the reading window

At regular intervals, check the reading window and the housing of the device for accu‐

mulated dirt. This is especially relevant in harsh operating environments (dust, abra‐

sion, damp, fingerprints, etc.).

The reading window lens must be kept clean and dry during operation.

NOTICE

Damage to the reading window.

Reduced analysis performance due to scratches or streaks on the window.

■

Clean the window only when wet.

■

Use a mild cleaning agent that does not contain powder additives. Do not use

aggressive cleaning agents, such as acetone, etc.

■

Avoid any movements that could cause scratches or abrasions on the window.

■

Only use cleaning agents suitable for the screen material.

NOTE

Static charge causes dust particles to adhere to the reading window. This effect can be

avoided by using an anti-static cleaning agent in combination with the SICK lens cloth

(can be obtained from

MAINTENANCE

9

8021817/10Y9/2018-09-14 | SICK

O P E R A T I N G I N S T R U C T I O N S | CLV60x

31

Subject to change without notice