3

Product description

3.1

Product ID

3.1.1

Type label

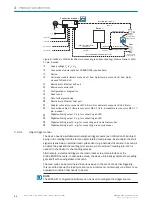

The type label gives information for identification of the device. An existing UL certifica‐

tion can be found on the type label.

1443 0297

S/N:

DC 10...30V 5.0W

1

2

3

4

5

Manufactured:

D-79276 Reute

Made in Germany

λ = 655nm

Pmax=1.5mW

P<1.0mW average

Pulse duration <300µs

Imax=700mA

P/N:

1068608

CLV610-C000

MAC

6

Figure 3: Type label design for the device, illustration may differ from actual type label

1

Type designation

2

Part number

3

Serial number

4

Laser output data

5

MAC address

6

Date of manufacture

25

3.1.2

Type code

The devices of the CLV63x, CLV64x, and CLV65x product families are arranged accord‐

ing to the following type code:

CLVxyz-abcde

CLV

x

y

z

-

a

b

c

d

e

1

2

3

4

5

6

7

8

9

Table 2: Type code

Position

Description

Characteristic

1

Code reader

V-principle

2 - 3

Product family

63: CLV63x

64: CLV64x

65: CLV65x

PRODUCT DESCRIPTION

3

8019588/129Z/2019-02-07 | SICK

O P E R A T I N G I N S T R U C T I O N S | CLV63x, CLV64x, CLV65x

13

Subject to change without notice