10

Troubleshooting

10.1

Overview of possible errors and faults

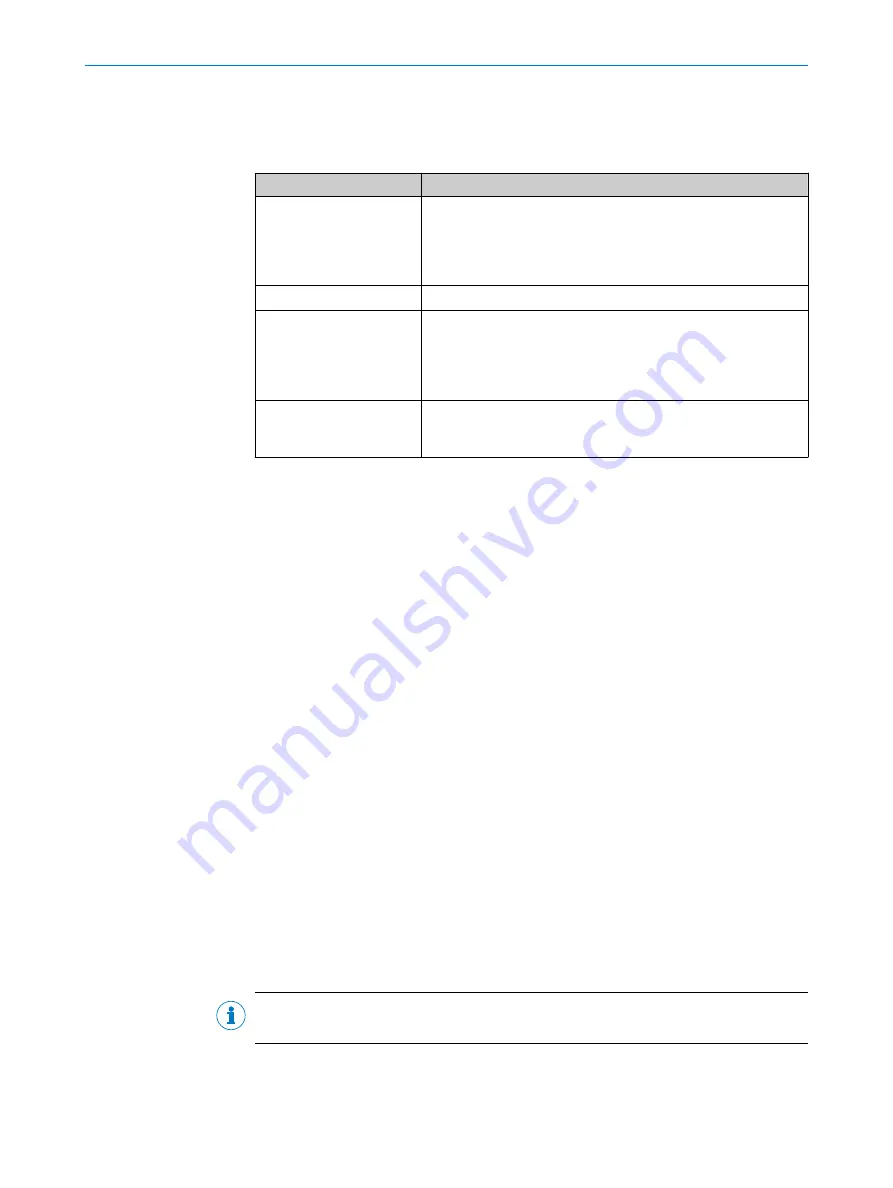

Situation

Error/fault

Mounting

■

Device poorly aligned to the object with the bar code (e.g.

dazzle).

■

Read cycle sensor incorrectly positioned (e.g., internal read‐

ing interval is opened too early or closed too late).

■

Incremental encoder incorrectly positioned.

Electrical installation

■

Data interfaces of the device incorrectly wired.

Configuration

■

Functions not adapted to local conditions, e.g. parameters

for the data interface not set correctly.

■

Device limits not observed, e.g. reading distance, aperture

angle.

■

Read cycle trigger source not selected correctly.

Operation

■

Read cycle control incorrect and/or not suitable for the

object.

■

Device faults (hardware/software).

Table 13: Errors and faults

10.2

Detailed fault analysis

10.2.1

LEDs on the device

The statuses that can be read from the device LEDs on the device housing (

ating and status indicators", page 52

) include:

■

Operational readiness (Ready)

■

Reading result status (Good Read or No Read)

■

Hardware fault

■

Firmware download status

■

Connection status of the device

The LED display can indicate any errors or faults with this. Further information for this

can be found in the system information.

10.2.2

System information

The device outputs faults in different ways. Fault output is staggered and thus allows

for an increasingly detailed level of analysis.

•

Communication errors can occur when transmitting data to the device. The device

then returns a fault code.

•

For faults that occur during reading, the device writes fault codes in the status log

(

.

10.3

Status log

NOTE

The status log is retained even after switching the device off and on again.

The device distinguishes between four types of fault:

■

Information

■

Warning

10

TROUBLESHOOTING

58

O P E R A T I N G I N S T R U C T I O N S | CLV63x, CLV64x, CLV65x

8019588/2017-01-20 | SICK

Subject to change without notice