Data

output

Trigger 2:

Stop

Trigger 1:

Start

R

e

a

d

ing

f

ie

ld

Start/stop operation

Figure 9: Start/stop operating mode of the device in stand-alone operation

NOTE

The SOPAS ET configuration software can be used to configure the reading operation

mode.

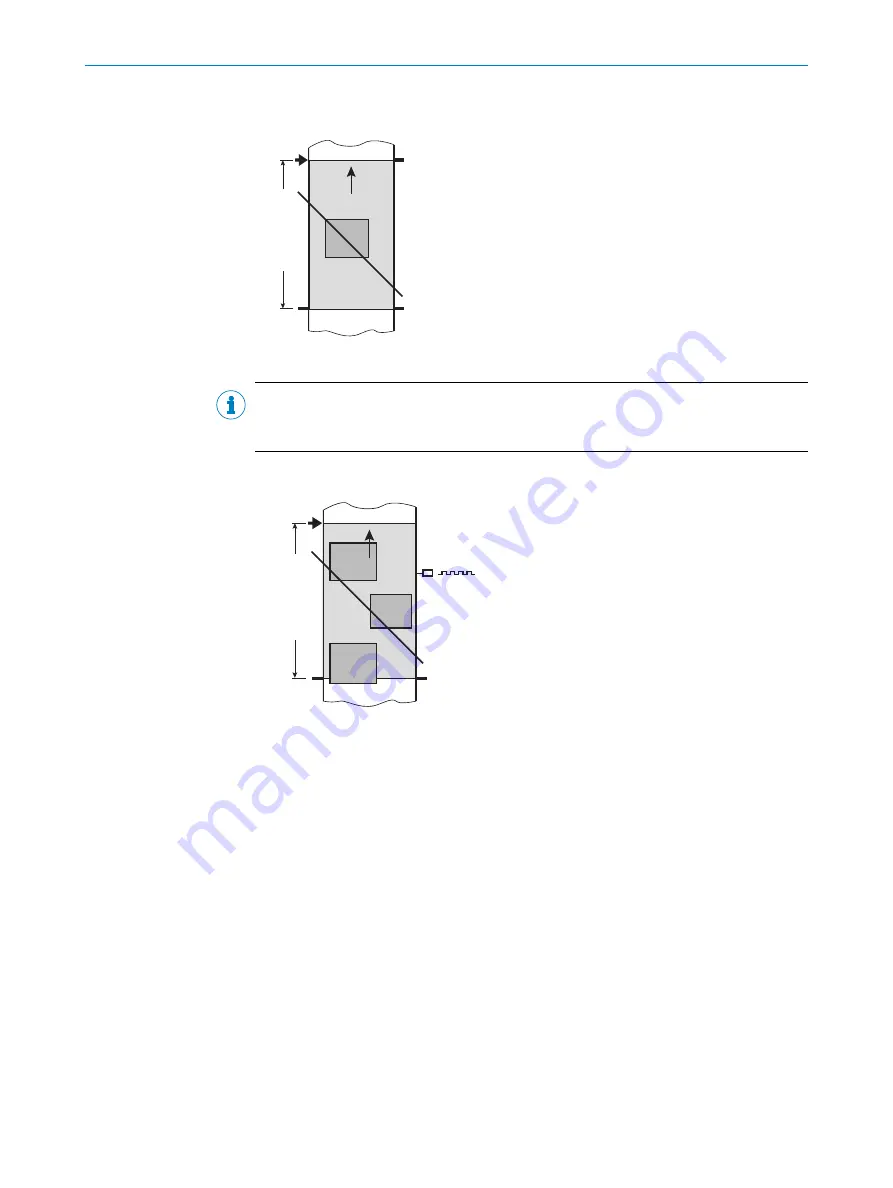

Tracking operation

Trigger 1:

Start

R

e

a

d

ing

f

ie

ld

Data

output

Figure 10: Tracking operating mode of the device in stand-alone operation

In the internal tracking operation, there are a maximum of 10 objects behind each

other in the reading field at the same time during the reading process.

As standard, the start of the reading process is controlled by a read cycle sensor at the

start of the reading field. The specification of the object release point defines the end.

This also defines the size of the resulting reading field.

In order to be able to track the transport of the objects in the reading field, a regular

cycle is required. This is generated by an external incremental encoder, which con‐

stantly provides at least one pulse per 1 mm movement in the conveyor direction. This

provides a clear temporal representation in the device of the route between the read

cycle sensor and object release point.

Jittering when the conveyor technology is starting up or in the event of slowing down

when there is a high load with lots of objects to convey is therefore also recorded. An

internal pulse generator in the device alternatively allows for operation at a conveyor

speed that is always constant.

A gap of at least 50 mm is necessary for clear separation of successive objects.

The issuing of the read result for an object is carried out after the rear edge of the

object passes the object release point. The reading process can alternatively be started

with a command string via the data interface.

PRODUCT DESCRIPTION

3

8014396/ZMG8/2017-07-04 | SICK

O P E R A T I N G I N S T R U C T I O N S | CLV69x

19

Subject to change without notice