Chapter

3

Operating Instructions

Laser measurement sensor LD-MRS

34

©

SICK AG · Germany · All rights reserved · Subject to change without notice

8012948/ZMQ0/2017-06-09

Product description

3.4.9

Impact of the object surface on the measurement

The signal received from a perfectly diffuse reflecting white surface corresponds to the defi-

nition of a remission of 100 %. As a result of this definition, the remissions for surfaces that

reflect the light bundled (mirrored surfaces, reflectors), are more than 100 %.

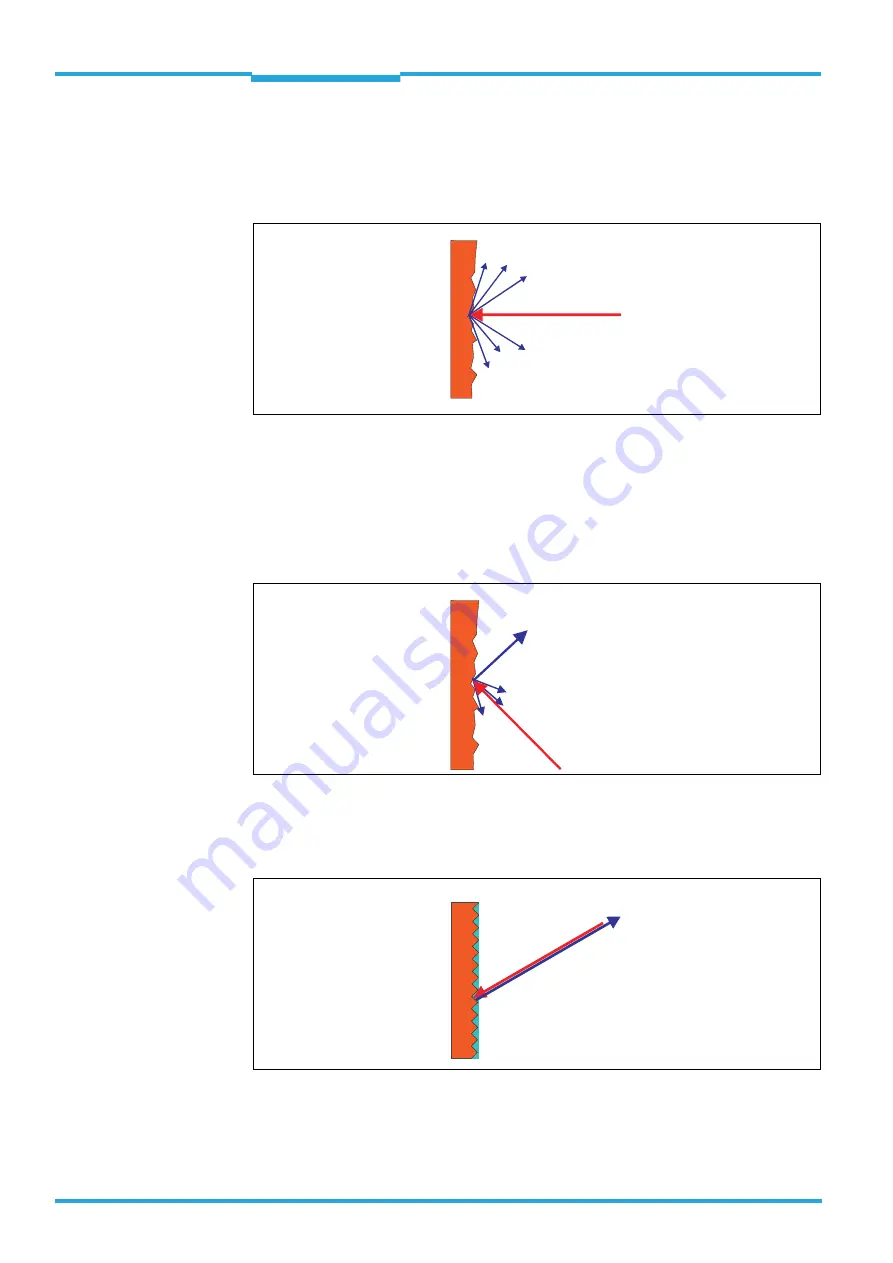

Most surfaces reflect the laser beam diffusely in all directions.

The reflection of the laser beam will vary as a function of the surface structure and colour.

Light surfaces reflect the laser beam better than dark surfaces and can be detected by the

LD-MRS over larger distances. Brilliant white plaster reflects approx. 100% of the incident

light, black foam rubber approx. 2.4 %. On very rough surfaces, part of the energy is lost due

to shading. This reduces the scanning range of the LD-MRS.

The reflection angle is the same as the angle of incidence. If the laser beam is incident per-

pendicularly on a surface, the energy is optimally reflected, see

. If the beam is in-

cident at an angle, a corresponding energy and scanning range loss is incurred.

If the reflected energy returned is over 100% (basis: Kodak standard) the incident beam is

not reflected diffusely in all directions, but is reflected in a specific direction. As a result a

Fig. 3-16:

Reflection of the laser beam at the surface of an object

Fig. 3-17:

Reflection angle

Fig. 3-18:

Degree of reflection