Chapter

8

Operating Instructions

Laser measurement sensor LD-MRS

92

©

SICK AG · Germany · All rights reserved · Subject to change without notice

8012948/ZMQ0/2017-06-09

Troubleshooting

8.4

Troubleshooting

The following tools are required for troubleshooting:

•

A digital measurement device (measuring current/voltage)

•

A computer with the SICK LaserView Customer Edition visualization tool and SOPAS-ET

configuration software

•

Tools

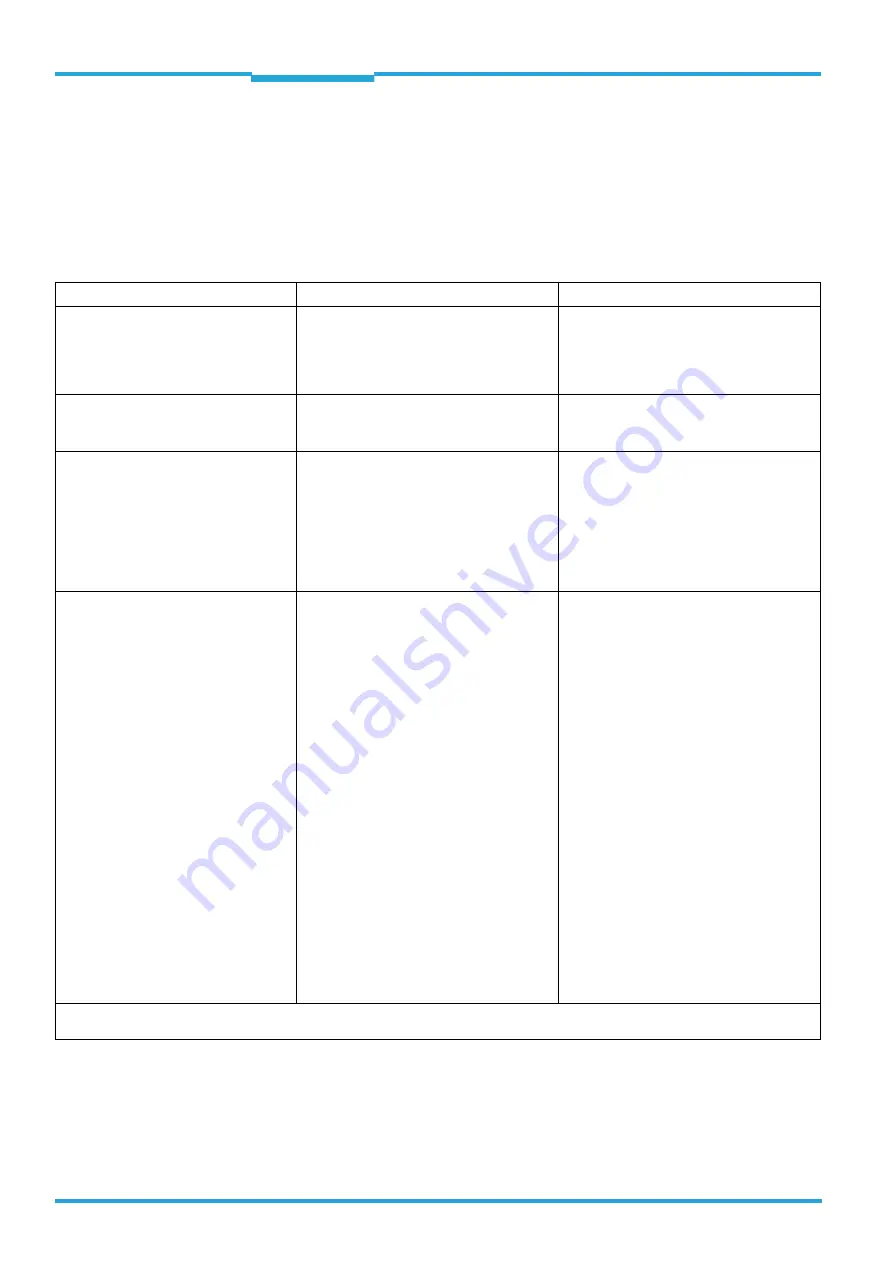

Fault

Possible cause

Rectification

1. SICK LaserView Customer Edition:

Configuration.

PC with SICK LaserView Customer Edi-

tion cannot communicate with the LD-

MRS.

• Supply voltage for LD-MRS not switched

on.

• PC not connected to LD-MRS.

• Check supply voltage, switch on.

• Connect PC via Ethernet interface of the

LD-MRS.

2. Measurement mode: no scan data.

• LD-MRS inconveniently mounted or ad-

justed.

• LD-MRS parametrized incorrectly.

• Mount LD-MRS at more suitable place or

readjust.

• Set correct parameters for the LD-MRS

.

3. Field monitoring:

No signals from the field violations

• Field not assigned to an evaluation in-

stance

• Switching output not activated or incor-

rectly configured

• In SOPAS-ET: check the evaluation in-

stance and provide the correct parame-

ters if necessary.

• In SOPAS-ET: check the CAN parameters.

Check the configuration of the external

outputs.

Check the wiring between the LD-MRS

and the CAN module.

4. Field monitoring:

The CAN modules are not working

(correctly) (optional accessory)

• The supply voltage V+ is not connected to

the CAN electronics, the poles are

switched or it is not turned on

• The supply voltage V

P

for the power driver

(switching outputs) is not connected

• Switch 8 for the CAN address dip switch

was accidentally set to 1

2)

(for program-

ming via an RS-232)

• Incorrect transmission rate

• Wrong termination

• CAN addressed several times

• The logical inputs/outputs in the LD-MRS

incorrectly assigned to the physical I/O

ports in the CAN modules

• The switching logic of the inputs/outputs

is inverted, active high, active low

• Connect the supply voltage (8 to 50 V DC)

to V+ and GND and turn on if necessary

• For example, bridge the supply voltage to

V+ to V

P

• Set switch 8 for the CAN address dip

switch to 0

2)

• In each CAM module, set a transmission

rate of 500 kBit/s (set the dip switch

transmission rate from left to right:

1110)

2)

• Activate the termination in both modules

with the Termination switch.

If there is only one CAN module, terminate

the open bus end with a 120 Ohm resis-

tance.

• Configure a unique CAN address for each

bus user

• Check the assignment of the logical in-

puts/outputs in SOPAS-ET

• Check the assignment of the switching

logic in SOPAS-ET

1) For additional assistance, see the chapter "Diagnosis" in the manual for the CAN module on the CD, "Manuals & Software LD-MRS“ (Part No. 2050246)

2) 1 = ON, 0 = OFF

Tab. 8-1: Troubleshooting the LD-MRS