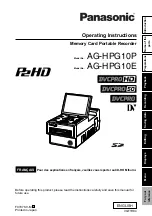

Ready

LED

Device status

Remarks

Green com‐

ponents

Red compo‐

nents

Ö

Ö

The

flashing

function is acti‐

vated via the configuration

software.

The red and green components of

the LED flash alternately.

Prerequisite: PROFINET is activated

in the device.

O

= lights up;

Ö

= flashes;

o

= does not light up

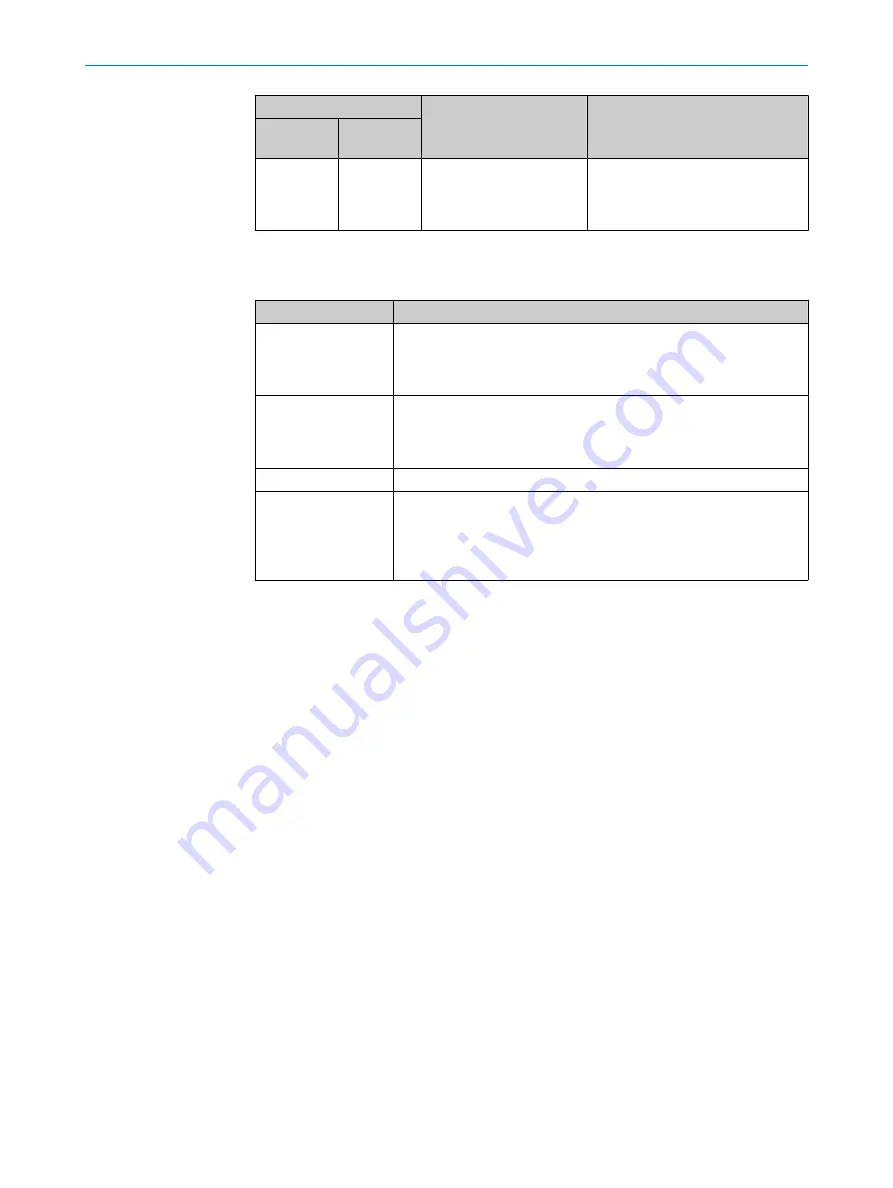

Device functions

Function

Description

Test

Checking stability of code reading:

The device records a series of images and uses the current reading

performance settings to decode them. To assess the code reading

stability, check the feedback LED.

Aiming

Switching LED alignment aid on and off:

The LEDs can be switched off so that the LED alignment aids do not

influence the code reading. To switch the LED alignment aid back on

again, run the

Aiming

function again.

Focus

Adjust focus position with the focus adjustment tool.

Tuning

The device adjusts itself automatically to suit the lighting conditions

and the quality of the code presented. Product type V2D61xx-xLxxxx

also automatically adjusts the focus position. The device permanently

stores the acquired values.

The

Tuning

function is not supported for pharmacodes.

Function button and device functions in configuration mode

The function button is used to call up device functions manually without using a

computer. On the third display level, the LEDs indicate the selectable device functions

and the execution of a device function.

Further topics

•

Adjusting focus with the focus adjustment tool

•

Configuration with operating buttons

3.6

Function and use

Thanks to its compact housing, the product can also be used where space is limited.

The lighting concept allows consistent code identification, regardless of the surface

or code color. The product can read the codes even for small codes, short reading dis‐

tances, weak contrasts, contamination or low code quality. Visible LED alignment aids

simplify the process of aligning the product to the code to be scanned. A time-of-flight

sensor measures the working distance of the product using invisible infrared light.

For product type V2D61xx-xMxxxx, the focus position can be adjusted manually with the

focus adjustment tool.

For product type V2D61xx-xLxxxx, the product can adjust the focus position automati‐

cally. To do so, use the function button to start the

Tuning

device function or the

Auto

Setup

function in SOPAS ET. If necessary, the focus position can be manually adjusted in

SOPAS ET.

The product does not have an AUX serial interface. An application-specific parameter

set created in SOPAS ET can therefore only be manually saved and archived as a

project file on the computer.

PRODUCT DESCRIPTION

3

8024830/1FGB/2022-03-29 | SICK

O P E R A T I N G I N S T R U C T I O N S | Lector61x

17

Subject to change without notice