3

Product description

3.1

Product variants

Flex product variant

The Flex product variant is a camera housing with a C-mount thread. The product

can be assembled from individual components to suit the particular application. The

individual components can be ordered separately as accessories. Use only products

from SICK as components.

3.2

Scope of delivery

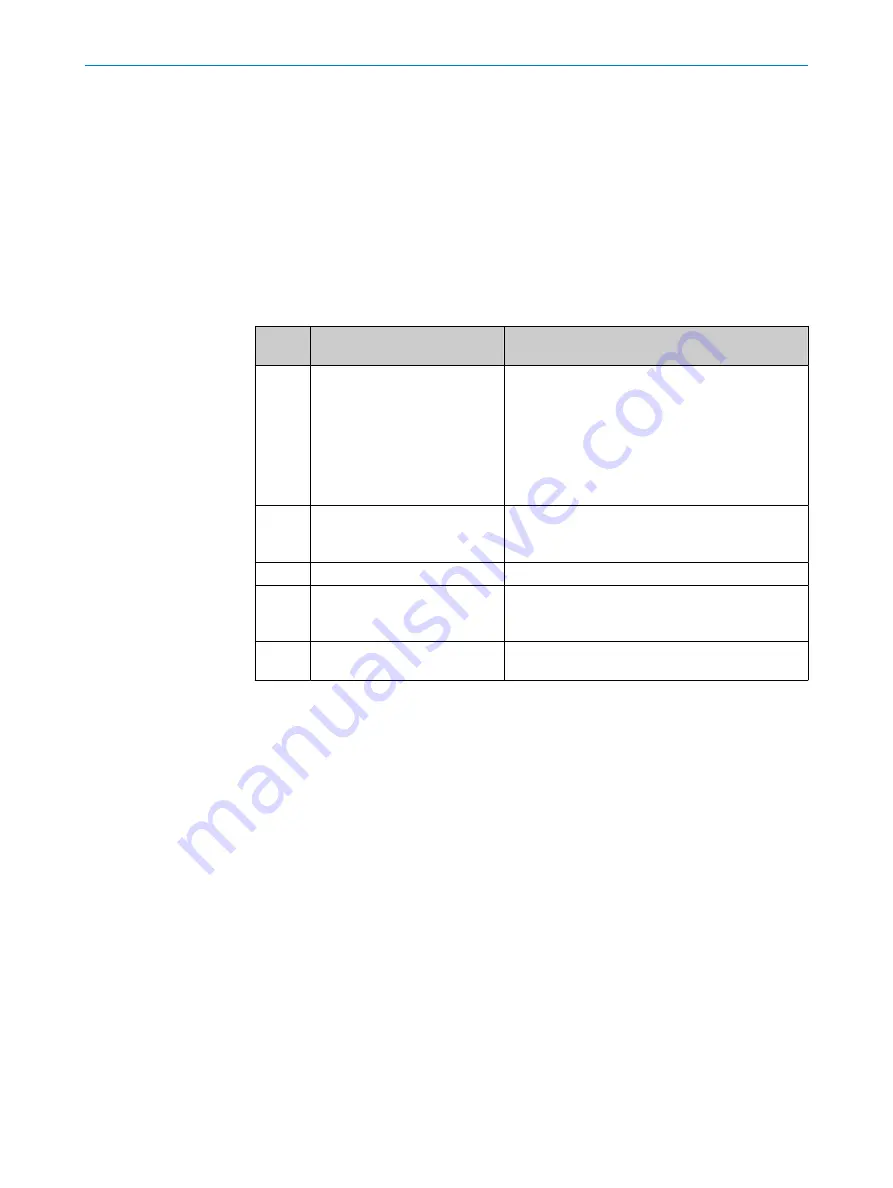

No. of

units

Component

Note

1

Device in the version ordered

•

Camera housing with C-mount threaded connec‐

tion

•

Order individual components separately as

accessories and mount them independently.

•

Light inlet is sealed with a protective cap.

•

Electrical connections are sealed with protective

caps.

•

Without holders and connecting cables

2

Sliding nut, 5.5 mm deep, with

M5 threaded fixing hole

•

Alternative mounting option for the device

instead of the threaded mounting hole

•

Use in pairs.

1

Hexagon key WAF 2

For mounting the integrated VI83I illumination unit

1

LED warning label RG 2 (self-

adhesive)

The LED warning label is included in the scope of

delivery of the separately-ordered RG 2 illumination

unit.

1

Printed safety notes, multilin‐

gual

Brief information and general safety notes

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

3.3

Product ID

3.3.1

Type label

The type label contains information for identifying the product.

3

PRODUCT DESCRIPTION

14

O P E R A T I N G I N S T R U C T I O N S | Lector85x Flex

8027859//2022-06-22 | SICK

Subject to change without notice