Table 6: Bore hole depth of piston rode and installation cavity for electrical connection

Null zone

MAX48: 30.0 mm

MAX30: 21.5 mm

Measuring range

As per the applicable data sheet and selected

device variant

Damping

NOTE

The total bore hole depth comprises the measuring range

1

, the

damping

2

, and

an

addition distance of 3 mm to the pressure pipe. Bore hole diameter (d) in the piston

(depending on type).

4.4

Encoder installation

1

2

1

Support ring

2

O-ring

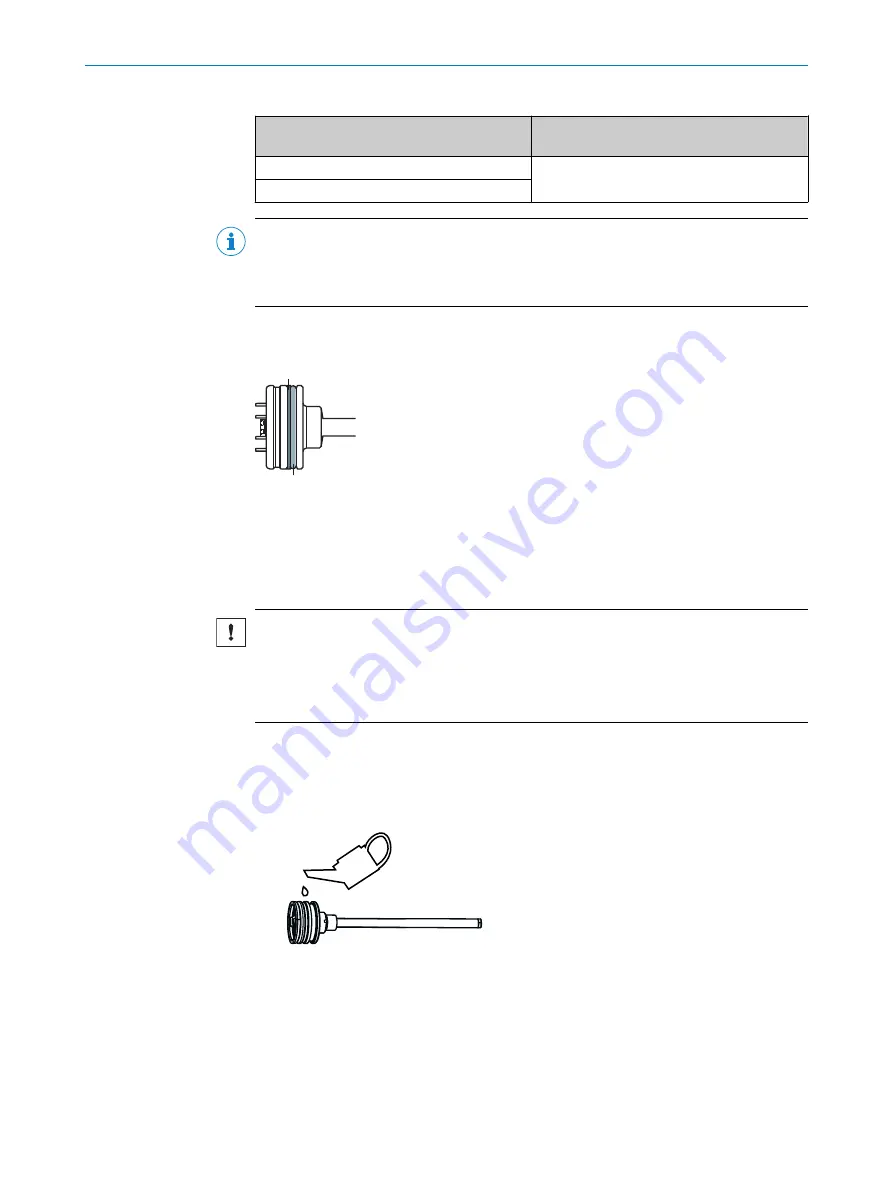

The O-ring and support ring are pre-installed as shown in the figure and prevent oil from

penetrating into the connector area.

NOTICE

Risk of damage to the connecting cables during mounting.

Tensile loads and sharp edges can damage the strands and connecting cables of the

male connector system.

Avoid tensile loads and look out for sharp edges when mounting the connector system.

4.4.1

Mounting in the cylinder

4.4.1.1

Insertion in the cylinder

1.

Lubricate the O-ring, support ring and pressure pipe.

2.

Carefully insert the encoder into the cylinder.

3.

Guide the connecting cable carefully through the cylinder wall (bore hole).

4

MOUNTING

24

O P E R A T I N G I N S T R U C T I O N S | MAX

®

8022793/1EFT/2021-12-15

| SICK

Subject to change without notice