DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

b

Make sure that the following control and electrical requirements are met so the

safety laser scanner can fulfill its protective function.

•

A restart interlock must be implemented depending on applicable national regula‐

tions or required reliability of the safety function. If a restart interlock is required, it

must be implemented in the external controller.

•

When using a safety controller, different signal levels of both OSSDs in an OSSD

pair must be detected depending on applicable national regulations or required

reliability of the safety function. The maximum discrepancy time tolerated by the

control must be selected according to the application.

•

In order to reach higher electromagnetic compatibility under rough electromag‐

netic ambient conditions, we recommend setting the input filter time of the con‐

nected control (on-off filter) to a value ≥ 5 ms. Please note that this increases the

response time of the total system by at least this set filter time.

•

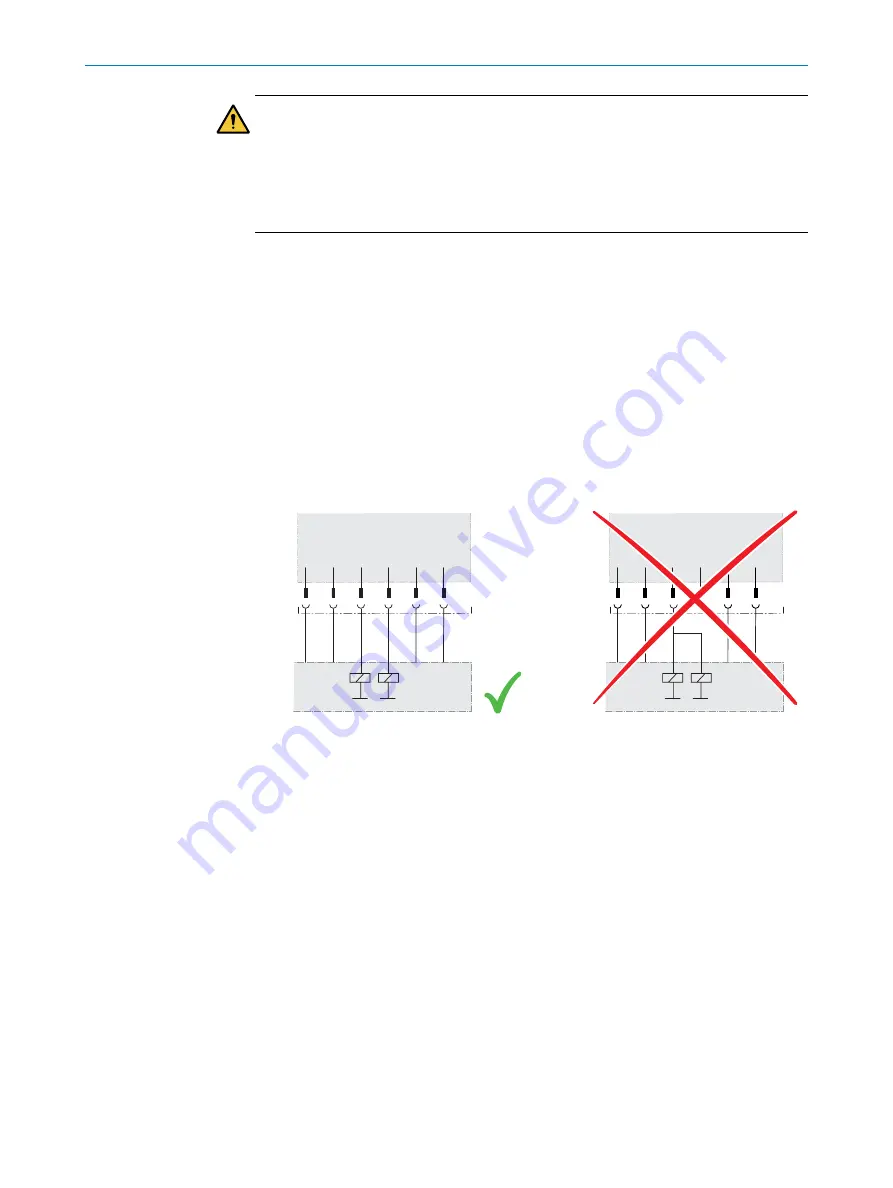

The output signals from an OSSD pair must not be connected to each other.

•

In the machine controller, both signals from an OSSD pair must be processed

separately.

O

S

SD A

O

S

SD B

O

S

SD A

O

S

SD B

Figure 33: Dual-channel and separate connection of the OSSDs of an OSSD pair

•

The machine must switch to the safe state if, at any time, at least one OSSD in an

OSSD pair switches to the OFF state.

PROJECT PLANNING

4

8017784/1ELL/2022-01-21 | SICK

O P E R A T I N G I N S T R U C T I O N S | microScan3 Core I/O AIDA

49

Subject to change without notice