4.4.5

Connection diagrams

deTec4

1

2

4

3

5

2)

3) PELV

r

S

ys

te

m conne

c

ti

on

+24 V DC

OSSD1

OSSD2

0 V

Com1

1

2

4

3

5

s

S

ys

te

m conne

c

ti

on

+24 V DC

In2

In1

0 V

Com1

F2 F1

F3

+24 V DC

0 V DC

K3

K2

K1

E243842/01/2019-10-11

F0

L+

L–

S1

k2

k1

z

k3

z

1)

k1

k2

x1

x2

x1

x2

k3

y1

y1

k3

k1

k2

R1

Y1

Y2

24

34

A2

14

S1

I1

I2

23

33

A1

13

RLY3-OSSD3

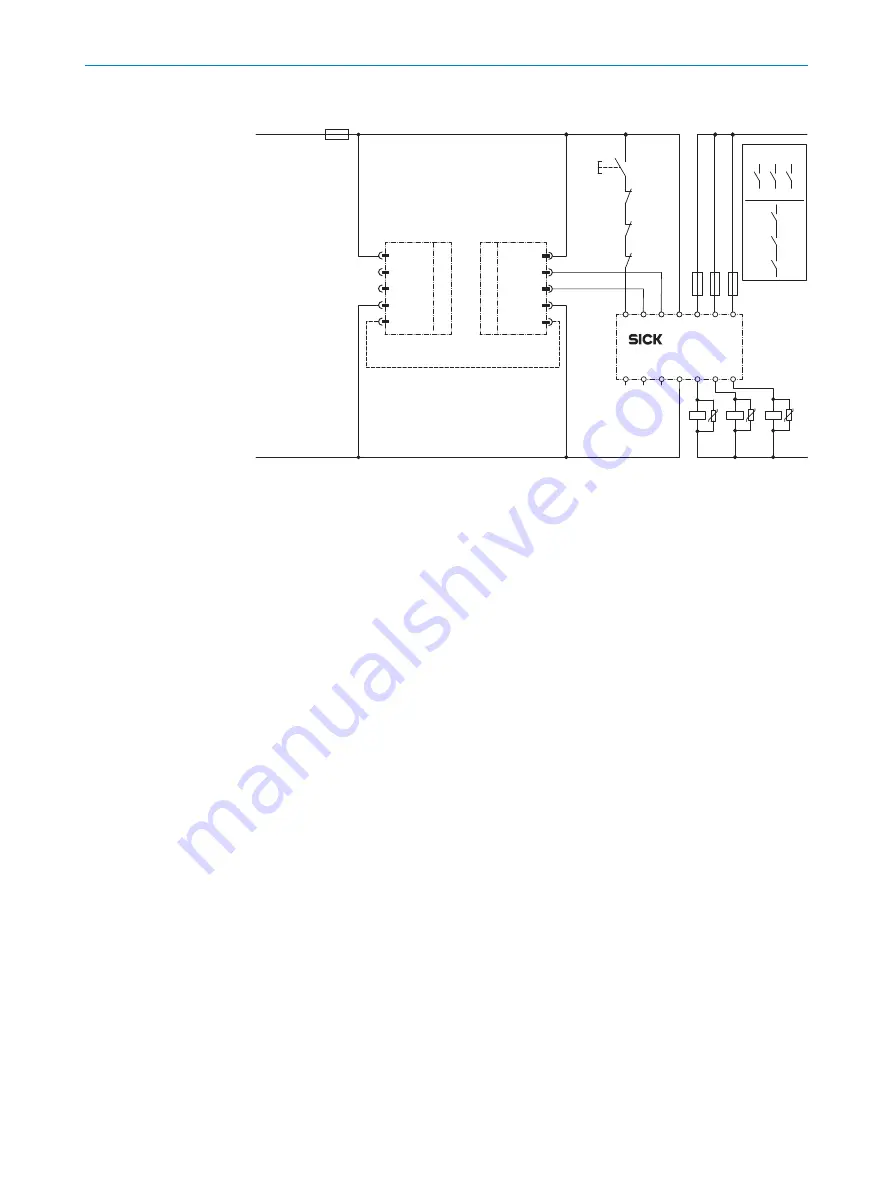

Figure 4: ReLy OSSD3 connection diagram

4.5

Testing plan

The safety relay must be thoroughly checked by appropriately qualified safety personnel

during commissioning, after modifications, and at regular intervals,

The regular thorough checks serve to assess the effectiveness of the safety relay and to

identify defects as a result of modifications or other influences (e.g., damage or manip‐

ulation).

The manufacturer and user must define the type and frequency of the thorough checks

on the machine on the basis of the application conditions and the risk assessment.

Determination of the thorough checks must be documented in a traceable manner.

4.5.1

Minimum requirements for the regular thorough check

The following thorough checks must be carried out at regular intervals:

•

Thorough check of the housing for damage

•

Thorough check of the cables for damage

•

Thorough check of the safety relay for signs of misuse or manipulation

•

Thorough check of the safety function

The minimum test interval depends on the applicable safety capability of the overall

application,

4

PROJECT PLANNING

14

O P E R A T I N G I N S T R U C T I O N S | ReLy OSSD3

8023925/2019-10-11 | SICK

Subject to change without notice