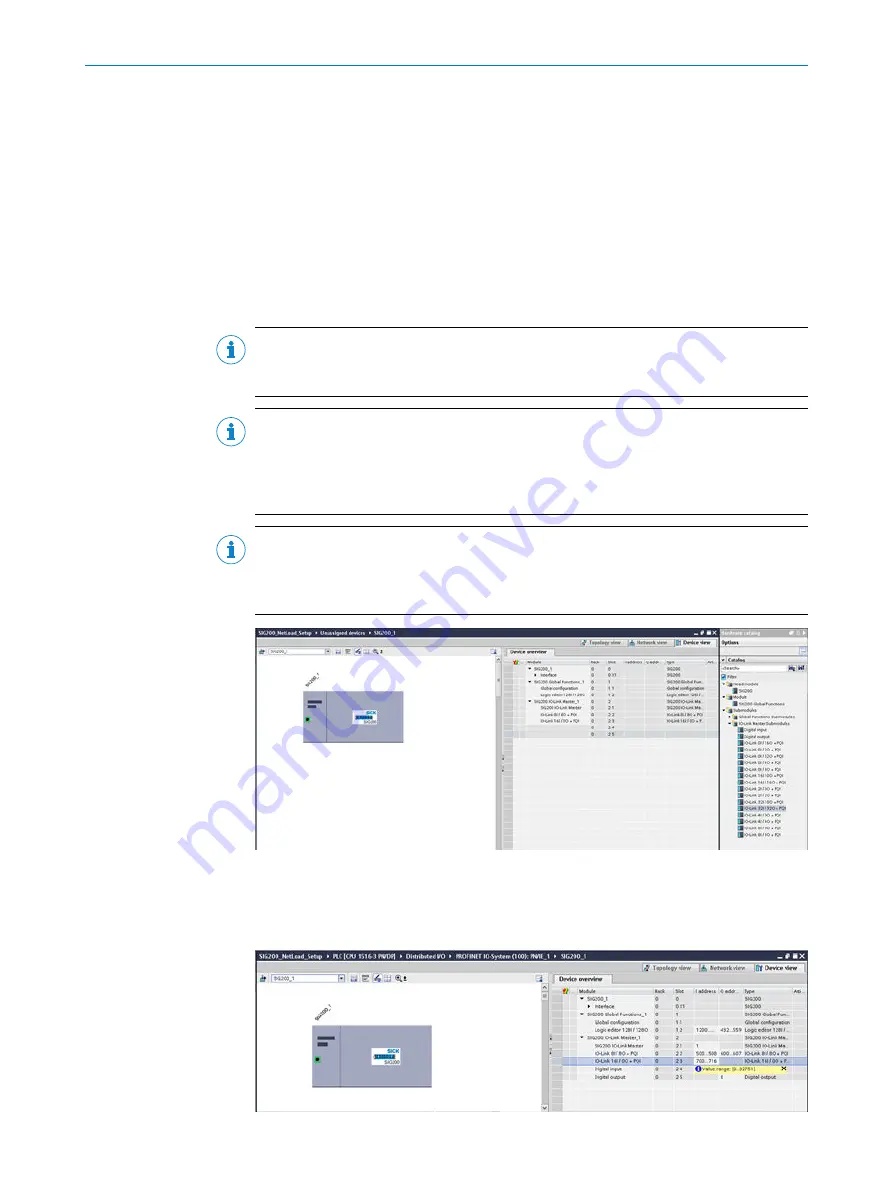

Next, the various subslots (2 to 5, corresponding to IO-Link ports 1 to 4, to which

IO-Link or standard I/O devices are connected) must be configured. In the catalog on

the right, select a suitable IO-Link submodule according to the process data length of

the IO-Link device. Drag and drop to the appropriate subslot (2 to 5).

Subslot 2.2. is linked to SIG200 Port S1.

Subslot 2.3 is linked to SIG200 Port S2.

Subslot 2.4 is linked to SIG200 Port S3.

Subslot 2.5 is linked to SIG200 Port S4.

Refer to the documentation for the IO-Link device for the required process data lengths

of the IO-Link device.

NOTE

When using the IO-Link device in SIO mode, use a digital input or digital output module

at the corresponding subslot.

NOTE

There is no parameterization for pin 2. Pin 2 is always 0 if there is no physical connec‐

tion. If a physical connection exists, the signal is automatically transmitted without

further parameterization and access can be made via SIG200-IO-Link master subslot

2.1.

NOTE

In order to get valid process data for the logic editor submodule 1.1, the Profinet input

and output process data in the logic editor must be connected (

).

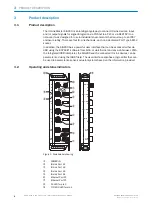

Figure 8: Device overview

7.1.1.5

Addressing modules

The I/O addresses can be selected and changed by selecting the IO-Link modules.

7

SIG200 CONFIGURATION

18

O P E R A T I N G I N S T R U C T I O N | Sensor Integration Gateway - SIG200

8017853.1D0S/2021-11-04 | SICK

Subject to change without notice