Reviews:

No comments

Related manuals for TB-110

PS 16

Brand: Olympia Pages: 74

314-872

Brand: Ativa Pages: 14

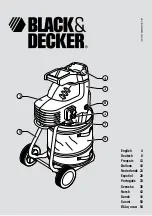

BD-890A

Brand: Black & Decker Pages: 2

SKU #BD-10P

Brand: Black & Decker Pages: 2

SKU #BD-VS600

Brand: Black & Decker Pages: 2

SKU #CC1000

Brand: Black & Decker Pages: 2

SKU #CC2000

Brand: Black & Decker Pages: 2

GA100

Brand: Black & Decker Pages: 52

GS2200

Brand: Black & Decker Pages: 64

GS2400

Brand: Black & Decker Pages: 72

GS1400

Brand: Black & Decker Pages: 92

GS1600

Brand: Black & Decker Pages: 96

SKU #BD-HS600

Brand: Black & Decker Pages: 2

DS-10

Brand: AMS Pages: 21

ECOPAX CP422S2-240V

Brand: optimax Pages: 6

BXMT4224

Brand: Wallenstein Pages: 52

1200X

Brand: Genie Pages: 31

106 S

Brand: Genie Pages: 31