2

SE80/185T & SE100/185T Ignition Protected thruster assembly

1.0 - 2007

Technical specifications

............................................................. 2

Planning & important precautions.............................................. 3

Stern thruster installation considerations................................... 3

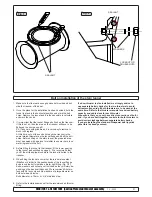

Bolt on installation .................................................................... 4

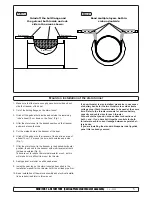

Mould on installation ................................................................. 5

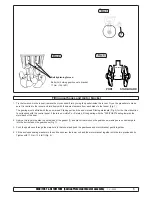

Gearhouse and motorbracket .................................................... 6

Oil tank & propellers ................................................................. 7

Electromotor IP assembly .......................................................... 8

Electrical installation ................................................................. 9

Control panel and control-leads............................................... 10

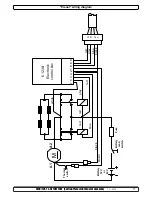

Visual wiring diagram .............................................................. 11

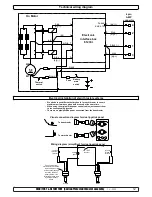

Technical wiring diagram ........................................................ 12

Electrical installation of stern thruster systems ........................12

Checklist .................................................................................. 13

Important user precautions ...................................................... 14

How to use Sidepower thrusters.............................................. 15

Maintenance ............................................................................ 16

Troubleshooting ....................................................................... 17

Warranty statement ................................................................ 18

Parts list ................................................................................... 19

Service centres ....................................................................... 20

Contents

Motor:

Custom made reversible DC-motor.

Gearhouse:

Seawater resistant bronze. Ballbearing at propellershaft; combination of ballbearing and slide bearing at

driveshaft.

Motor bracket:

Seawaterresistant aluminium.

Ignition protection:

Conforms to ISO 8846

Propeller:

5 blade skew "Q"-propeller

, fibreglass reinforced composite.

Batteries:

Minimum recommended battery capacity (cold crank capacity by DIN standard)

SE 80/185T 12V : 550 CCA DIN/1045 CCA SAE

SE 80/185T 24V : 300 CCA DIN/570 CCA SAE

SE 100/185T 12V : 750 CCA DIN/1425 CCA SAE

SE 100/185T 24V : 400 CCA DIN/760 CCA SAE

Max. use:

S2 = 3 min. or appr. 7-10% within a limited time frame. All electromotors are protected against overheating.

Safety:

Electronic time-lapse device protects against sudden change of drive direction. Electric thermal cut-off switch in

electromotor protects against over heating (auto reset when electro motor cools down).

Flexible coupling between electro-motor and driveshaft protects electromotor and gearsystem if propeller gets

jammed.

If original Sidepower panel is used, the panel shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids, reducing wear and risk of solenoid lock-in. Auto-stop of thruster in

case of accidental solenoid lock-in or if run signal is continous for more than 3 minutes.

Technical specifications

DECLARATION OF CONFORMITY

We,

Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad, Norway

declare that this product with accompanying

standard remote control systems complies with the

essential health and safety requirements according

to the Directive 89/336/EEC of 23 May 1989

amended by 92/31/EEC and 93/68/EEC.

2

SP75Ti / SP95Ti ignition protected thruster assembly

1.2.1 - 2007

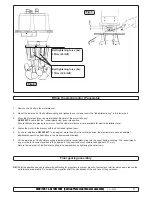

A

B

W.L.

C

Technical specifications ......................................................... 2

Planning & important precautions ......................................... 3

Stern thruster installation considerations ............................. 3

Bolt on installation .................................................................. 4

Mould on installation ............................................................... 5

Gearhouse and motorbracket ................................................ 6

Oil tank & propellers .............................................................. 7

Electromotor IP assembly ...................................................... 8

Electrical installation ............................................................... 9

Control panel and control-leads .......................................... 10

Visual wiring diagram ........................................................... 11

Technical wiring diagram ..................................................... 12

Electrical installation of stern thruster systems ................... 12

Checklist ............................................................................... 13

Important user precautions .................................................. 14

How to use Sidepower thrusters ......................................... 15

Maintenance .......................................................................... 16

Troubleshooting .................................................................... 17

Warranty statement ............................................................... 18

Parts list ................................................................................ 19

Service centres ...................................................................... 20

Contents

Motor:

Custom made reversible DC-motor.

Gearhouse:

Seawater resistant bronze. Ballbearing at propellershaft; combination of ballbearing and slide bearing at

driveshaft.

Motor bracket:

Seawaterresistant aluminium.

Ignition protection:

Conforms to ISO 8846

Propeller:

Symmetrical 4 blade kaplan propeller, fibreglass reinforced composite.

Batteries:

Minimum recommended battery capacity (cold crank capacity by DIN standard)

SP 75 Ti IP 12V : 500 CCA DIN / 24V : 250 CCA DIN

SP 95 Ti IP 12V : 700 CCA DIN / 24V : 350 CCA DIN

Max. use:

S2 = 3 min. or appr. 7-10% within a limited time frame. All electromotors are protected against overheating.

Safety:

Electronic time-lapse device protects against sudden change of drive direction. Electric thermal cut-off

switch in electromotor protects against over heating (auto reset when electro motor cools down).

Flexible coupling between electro-motor and driveshaft protects electromotor and gearsystem if propeller

gets jammed.

If original Sidepower panel is used, the panel shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids, reducing wear and risk of solenoid lock-in. Auto-stop of thruster in

case of accidental solenoid lock-in or if run signal is continous for more than 3 minutes.

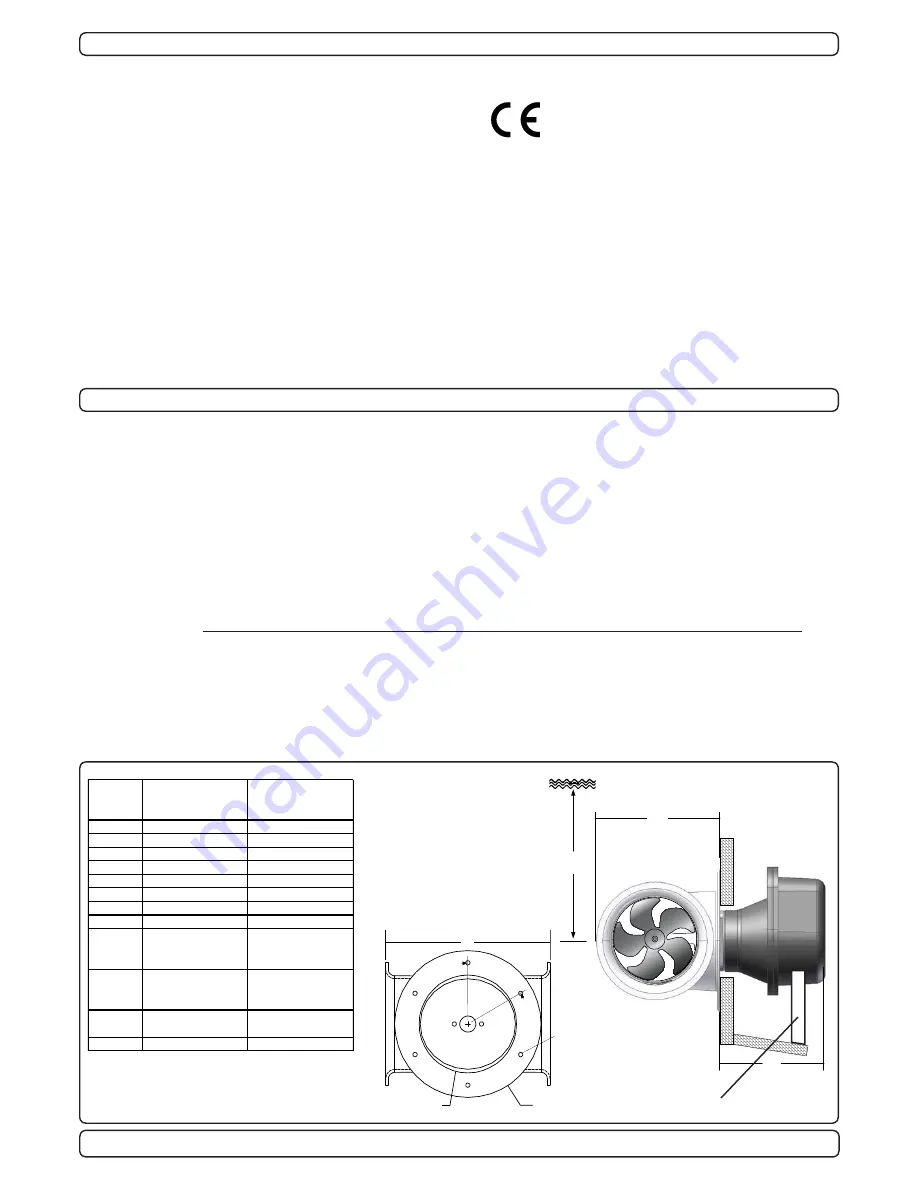

Technical specifications

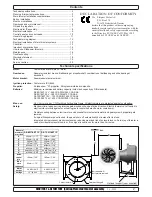

Outside of flange: E

Cut out in stern: F

Bolt holes dia: G

Bolt position radius: H

60°

D

DECLARATION OF CONFORMITY

We, Sleipner Motor AS

P.O. Box 519

N-1612 Fredrikstad, Norway

declare that this product with accompanying

standard remote control systems complies with the

essential health and safety requirements according

to the Directive 89/336/EEC of 23 May 1989

amended by 92/31/EEC and 93/68/EEC.

Measure

ments ref.

mm / inch

SP75 Ti IP

A

299mm / 11,77"

B

256mm / 10,08"

C

200mm / 7,87"

D

337mm / 13,3"

E

ø300mm / 11,8"

F

ø200mm / 7,84"

G

6x ø10,5mm / 0,41"

H

ø129mm / 5,08"

Inside

tunnel

dia.

185mm / 7,28"

Max.

stern

thickness

4

5

mm /

1

,

75

"

Motor

output

4,4 KW / 6 HP

Voltage

12 / 24 Volt

SP95 Ti IP

407mm / 16,02"

256mm / 10,08"

200mm / 7,87"

337mm / 13,3"

ø300mm / 11,8"

ø200mm / 7,84"

6x ø10,5mm / 0,41"

ø129mm / 5,08"

185mm / 7,28"

4

5

mm /

1

,

75

"

4,4 KW / 6 HP

12 / 24 Volt

SE 80/185T IP SE 100/185T IP

Optional support (user supplied)