H39.MFVRS004EN-00

02.2019

13/64

Assembly instructions

Multi-point locks, key operated

BS 230X, BS 250X, BS 260X

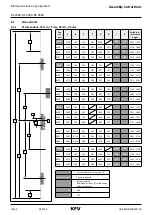

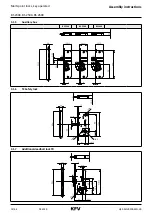

3.1.4

Main lock types, key-operated

Variable dimensions in mm

Main lock type

Cylinder lock

PZ/RZ

PZ dimen-

sion

[E]

Backset

[D]

Rear backset

[L]

Deadbolt pro-

jection

[R]

[M]

[N]

[O]

[P]

[Q]

[S]

V

PZ

72

55, 65, 70, 80

17.5

20

29

57.5

12.5

51.5

47

12

V

RZ

74

55, 65, 70, 80

17.5

20

29

57.5

12.5

49.5

47

12

H

PZ

85

25

17.5

Without dead-

bolt

36

50.5

19.5

31.5

52

8

H

PZ

85

30

17.5

10

36

50.5

19.5

31.5

52

8

H

PZ

85

35

17.5

16

36

50.5

19.5

31.5

54

12

H

PZ

85

40 - 80

17.5

20

36

50.5

19.5

31.5

54

12

H

PZ

88

35

17.5

16

33

53.5

16.5

31.5

51

12

H

PZ

88

40 -80

17.5

20

33

53.5

16.5

31.5

51

12

H

PZ

92

25

17.5

Without dead-

bolt

29

57.5

12.5

31.5

45

8

H

PZ

92

30

17.5

10

29

57.5

12.5

31.5

45

8

H

PZ

92

35

17.5

16

29

57.5

12.5

31.5

47

12

H

PZ

92

40 -80

17.5

20

29

57.5

12.5

31.5

47

12

H

RZ

94

35

20.3

16

29

57.5

12.5

29.5

47

12

H

RZ

94

40 -80

20.3

20

29

57.5

12.5

29.5

47

12

Figure: PZ

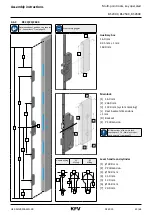

Figure: RZ

D

L

R

S

M

E

O

N

Q

P

6,5

53,5

3*

milling dimensions

system

marker

D

L

E

P

* This dimension refers to a flat face plate 3 mm, galvanized steel.

This dimension and other dependent dimensions could change if other faceplates are used.