02.2019

4/44

H39.MFVRS006EN-00

Multi-point locks, key operated

Assembly instructions

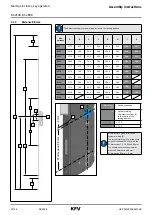

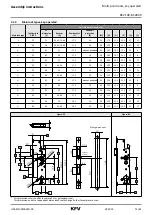

BS 2100, BS 2800

1

Introduction

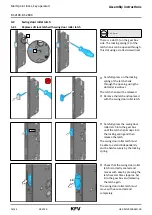

Please read these instructions carefully before you

begin the assembly work. Follow the instructions in

Chapter 2 “Safety”, in order to prevent personal injury

or functional disorders.

These instructions are an integral part of the multi-

point lock and must be accessible to the specialist

personnel at all times.

1.1

Manufacturer and Service

KFV Karl Fliether GmbH & Co. KG

A company of the SIEGENIA GROUP

Siemensstraße 10

42551 Velbert

Tel.: +49 2051 278-0

Fax: +49 2051 278-167

E-Mail: info@kfv.de

Please contact your retail partner in case of complaints

or service requirement.

1.2

Target group of this documentation

This documentation is intended for use by specialists

only. All work described in this document is to be

performed only by experienced professionals with

training and practice in the assembly, as well as the

commissioning and maintenance of multi-point locks.

1.3

Intended use

1.3.1

Installation location

•

The multi-point lock is suitable for installation in

single-sash and double-sash doors in permanent

buildings.

•

The multi-point lock may only be installed in doors

that have been fitted in a technically sound manner.

•

The door design must permit use of the multi-point

lock.

1.3.2

Locking part and hardware

•

Use only KFV frame parts.

1.4

Improper use

•

The multi-point lock must not be used for escape

doors.

•

The multi-point lock is not designed to

accommodate changes to its shape or sealing which

arise as a result of differences in temperature or

changes to the building beyond the adjustment path

of the Q adjustment.

•

The multi-point lock must not be used in doors

for wet rooms or rooms in which the air contains

aggressive or corrosive components.

•

Foreign objects and/or materials which impede or

prevent proper use must not be placed within the

opening range, the locking system or the frame

parts.

•

Do not interfere with and/or make any

modifications to the multi-point lock.

•

Locking elements must not be misused to hold the

door open.

•

Movable or adjustable locking elements

(e.g. deadbolt, latch) must not be painted over.

1.5

Installation conditions and requirements

Local building laws and regulations must be observed

before and during door installation in addition to the

following requirements and conditions:

•

Before installing the multi-point lock, check the

dimensional accuracy of the door and the door

frame. The multi-point lock must not be installed

if the door and/or the frame is warped and/or

damaged.

•

Surface treatment of the door and door frame must

take place before the multi-point lock is installed.

Subsequent surface treatment can reduce the

functional capacity of the multi-point lock.

•

Observe the specified positions and sizes for all

milling and drilling dimensions within the defined

tolerances. Observe the horizontal and vertical

adjustment accurately.

•

Remove any splinters from routed pockets after

milling.

•

Do not overtighten the screws or insert them at an

angle.

•

Once the multi-point lock is installed, do not

perform mechanical work on the door (such as

drilling or milling).

•

Do not drill into or through the main lock under any

circumstances.

•

Install hardware components and cylinder flush.

•

Adhere to airgap (interval between faceplate and

frame parts): The multi-point lock functions safely

with an airgap between 3.5 mm +/- 1.5 mm. Beyond

this, the fabricator must ensure that the airgap

is large enough to guarantee the freedom from

constraint of the door.

•

Use only acid-free neutral-cure sealants to prevent

corrosion of components and/or the door.