H48.HSKFS0023EN

12.2019

9/66

PremiDoor 88

Processing speci

fi

ca ons

PORTAL

HS

4 Processing

speci

fi

ca ons

To comply with the requirements of EN13126-16, a

handle length of 225 mm must be used.

The components of the li and slide element must be

stored at room temperature (20°C) for 24 hours before

processing.

For adhesion and sealing work, we recommend

– OTTO Chemie-OTTOSEAL® S 72

– Collano Adhesives AG-Collano® A 1970

– or a similar product.

The PORTAL HS hardware in this

documenta on is designed for the pro

fi

le

systemsPremiDoor 88. Subsequent adjustments

can be made due to the system dimensions

in

fl

uenced by the hardware. If a devia on

from the system dimensions is only detected

a er the installa on in the window, the

hardware manufacture will not be liable for any

addi onal expenditure incurred.

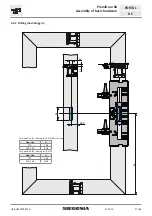

4.1 SI

construc on drawings

The dimensions of the SI construc on drawings must

be observed for the correct posi oning of the holes

and the components on the pro

fi

le.

You can obtain SL construc on drawings from the

fi

eld

sales contact person on request.

4.2 Applica on diagram

It is essen al to observe the applica on diagram for PORTAL HS

H58.AWD_P_S004EN.

You can obtain applica on diagrams from the sales

contact person on request.

4.3 Test

reports

Produc on of the li and slide elements according to

the PORTAL HS system drawings is essen al for the use

of the SIEGENIA test reports for PORTAL HS. You will

obtain these from the sales

fi

eld service.

Moreover, a wide range of individual systems can be

con

fi

gured with the completely preassembled li -

slide package COMFORT UNIT. The test reports for this

purpose must be provided by the window producer.

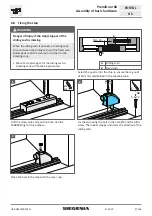

4.4 Threshold

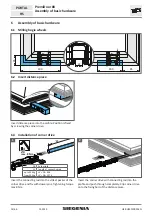

Seal the threshold components and seal between

the threshold and masonry or facade observing the

applicable rules in the trade.

The threshold must be lined at intervals of 300 mm to

be pressure- ght and sound-absorbing.

We recommend the use of stainless steel screws for the

assembly of components on the ECO PASS threshold.

You will

fi

nd informa on about sill installa on here:

h p://www.bauanschluss.ch

Sill installa on manual

The sill installa on manual from SIEGENIA contains

comprehensive informa on about sill installa on.

You can obtain the relevant informa on on request

from your sales contact person.