01.2022

32/108

H48.HSKFS0031EN

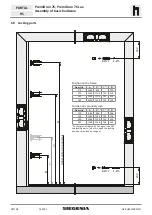

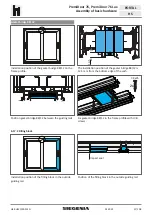

PORTAL

PremiDoor 76,

PremiDoor 76 Lux

Assembly of basic hardware

HS

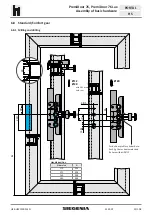

6.14

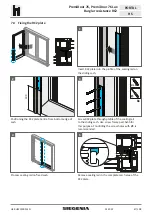

Stop buffer

6.14.1

Stop buffer rod

15

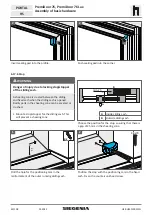

Assembly.

without

spacers

Assembly.

with

spacers

Reinforcement

V372

Reinforcement

V371

1

When reinforcement V192 is installed in the

sliding.sash,.two.spacers.D20.must.be.mounted

2

2x

4.8x38

Fix.stop.buffer.rod.to.the.profile.with.drill.screws.

Fixing.position.for.stop.buffer.rod.on.the.sliding.sash.

3

4

Dimension.with.lifted.sash