22.11.2013

Page 1

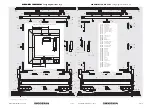

PSK PORTAL 160 PLUS LM

Parallel tilt & slide (PSK) hardware

For light metal profiles a cavity of 21 mm

Assembly instructions

H48.PSKLMS001EN

Tech

nica

l sp

ecificatio

ns a

nd

co

lo

urs are

subjec

t to

ch

an

ge

Table of contents

Size range............................................................. Page 1

Vertical section, top....................................................................Page 11

Layout of fittings.................................................... Page 2

Horizontal section (l)..................................................................Page 12

List of fittings part1 ............................................... Page 3

Horizontal section (II) ................................................................Page 13

List of fittings part2 ............................................... Page 4

Frame: frame part dimensions ...................................................Page 14

Important instructions, abbreviations................... Page 5

Window frame: mounting the running and guiding rail ..........Page 15

Design variations .................................................. Page 6

Vertical section, bottom..............................................................Page 16

Fitting diagram scheme C (I) ............................... Page 7

Preparing the sash frame...........................................................Page 17

Fitting diagram scheme C (II) .............................. Page 8

Sash: ZV assembly .....................................................................Page 18

Scheme C.............................................................. Page 9

Sash frame: mounting the PSK components .............................Page 19

Hinging and unhinging the stay arms ................. Page 10

Inserting the sliding sashes and adjustment possibilities..........Page 20

The size ranges mentioned above apply for the PSK-PORTAL 160 PLUS LM fitting from SIEGENIA.

Also effective are the specifications of the profile manufacturers or system owners,

especially

with regard to

possible restrictions on sash dimensions, sash weight and lock spacing.

Observe any special manufacturing specifications or processing guidelines explicitly.

Size range

Sash width

(mm)

700 to 1,650

1)

Sash height

(mm)

850 to 2,400

Exterior width of frame

(mm)

Depends on the profile system,

determined by the sash width,

for scheme A: max. 3,460

Rebate thickness

(mm)

7 to 12

Sash weight

(kg)

Max. 160

Total frame to sash clearance

(mm)

118

1) For sash widths < 960 mm, the sash height must not be greater than 2.5x the sash width.