General information

All information and instructions contained in

instruction manuals or any other instructions

supplied must be observed.

This is indispensable for the avoidance of risk and damage! An

additional safety information sheet is enclosed (yellow) which provides

supplementary information on the safety of electrical machinery and

equipment. These safety instructions are therefore also intended to

supplement all other instruction manuals or any other instructions

supplied.

Furthermore, the applicable national, local and plant-specific

requirements and regulations must be observed!

The technical specifications of special versions and design

variations may differ from those specified! If you have any doubts

whatsoever, we strongly advise that you consult the manufacturer,

giving details of type designation and serial number, or that you have

the service work carried out by a SIEMENS Service Center.

3

Maintenance

3.1

General information

It is assumed that maintenance work is carried out by qualified personnel

(for definition of qualified personnel, see DIN VDE 0105 or IEC 364).

After carrying out maintenance work, refer to Section 2, Operation in the

Instructions for 1FT5 motors (610.41199.21) again!

Safety precautions

Before carrying out any work on the motor or unit, and

especially before uncovering live parts,

disconnect the motor from the power

supply. Remember to disconnect any

supplementary or auxiliary circuits as well as the main circuits.

The standard "5 safety rules" according to DIN VDE 0105

apply:

-

Disconnect from the power supply

-

Secure against reconnection

-

Check that equipment is dead

-

Earth and short-circuit

-

Cover or screen off all live adjacent parts

The above actions may only be reversed when all repair work

has been completed and the motor has been completely re-

assembled.

The system must be disconnected from the

power supply before any work is carried out!

Due to the fact that the motors contain perma-

nent magnets, a voltage is generated at the motor terminals when

the rotor is turned.

When removing or fitting parts, make sure that connecting leads are not

damaged, are not under tension and can not come into contact with

moving parts.

Encoder systems, e.g. ROD 320, ROD 426, absolute

value encoder, tachogenerator, or parts which bear

the symbol shown on the left are ESD-sensitive

components and assemblies.

These components and assemblies are sensitive to electrostatic discharge.

Disassembly and assembly should only be carried out where there is

suitable earth protection!

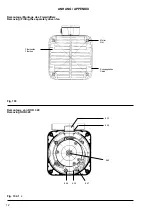

3.1.1 Disassembly

Before disassembly of the motor (e.g. to replace bearings), the original

position of the endshields relative to the motor housing should be marked

(e.g. with coloured marker or marking tool) in order to simplify refitting.

3.1.2

Assembly

Damaged parts must be replaced. Use only spare parts and attachments

approved by the manufacturer.

If seals are fitted to meet the specified degree of protection, they must be

inspected and replaced if necessary.

NOTE: We recommend replacing all seals between parts which are

removed. The seals should be made of FPM (fluor caoutchouc).

Sealing faces without O-rings should be sealed with a sealant (e.g.

Fluid D by Teroson, Heidelberg).

Screws or nuts which are secured with locking, spring-loaded and/

or force-imparting elements (e.g. lock washers, spring washers, etc.)

must be refitted in the same way. Such locking elements must always be

replaced.

All screws without locking elements must be secured with Loctite

243, except for screws for the terminal clamps,

the terminal box cover and the top parts of the

terminal box. These screws perform a

protective earth function and must neither be removed nor coated

with anything which might insulate the screws against the housing

or the terminal box (e.g. Loctite ....).

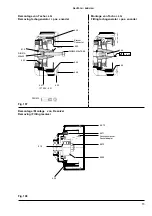

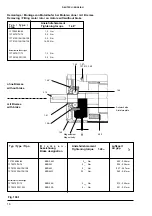

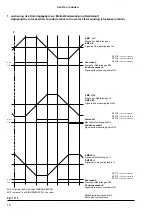

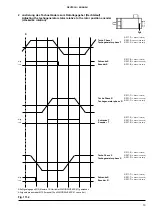

For screw connections, the tightening torques given in Fig. 112 apply

unless otherwise stated in the operating instructions or other instructions

supplied.

3.2

Replacing the bearings, types of grease

We recommend that the bearings be replaced after approx. 20,000 hours

of operation or after 3 years at the latest. The motors have permanently

lubricated bearings with radial clearance C3 and seals or covers at both

ends. The bearings must be suitable for operation at temperatures

between -10°C and +150°C.

Types of grease for standard motors: UNIREX N3 (Esso); replacement

grease must conform to DIN 51825/K3N.

NOTE: When replacing bearings, the new bearings should have

good seals which match the quality of the original bearings. Check

the bearing inscription and orientation of D-end and N-end bearings!

We recommend that replacement bearings be ordered from the

manufacturer so that special requirements such as bearing clearance

and/or seal material can be taken into account.

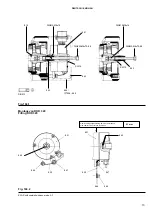

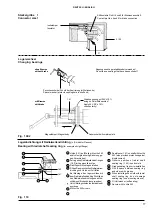

Removing (/Fitting) sequence

See Fig. 102.2

3.3

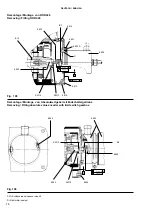

Removing/Fitting the separately driven fan

Removing (see Fig. 103)

- Remove filter box by unhooking the catches

- Unscrew nuts

- Remove fan from motor

Refitting

- Place fan on motor in correct position, if necessary clean filter insert

- Tighten screws

- Observe circuit diagram and arrow showing correct direction of rotation!

ENGLISH

8