ENGLISH

Siemens AG

610.40068.01

11

-

Ensure the waste heat is adequately dissipated.

-

It is recommended to maintain a clearance of 100 mm from adjacent parts on the least

three sides.

-

Tighten the flange equally, avoid distortions when tightening fixing screws. Use hexagon

socket head cap screws, strength class at least 8.8.

-

In the case of a vertical installation with the shaft end at the top, ensure that no fluid

penetrates into the upper bearing.

-

Turn the output elements by hand. If grinding noises occur, eliminate the cause or

contact the manufacturer.

Precheck for explosion proof

After checking all datas in the technical standard manuals it is recommended to check all

datas according to regulation of explosion proof e.g.

a) gas group

b) temperatur class

Please note that the motors are classified and certificated according to their group. The

respective group result from the environment gas and the temperature class and is

calculated as a function of the environment temperature of 40°C (104°F).

Vibrations, balancing

Motors with a keyway are balanced by the manufacturer with a half feather key. The site

vibrations response of the system is determined by the output elements, the mounting

conditions, the alignment, the installation and the effects of external vibrations.

This may cause a modification of the motor vibration values.

The vibrations immited in the fitted state must not exceed acceleration of 5 g.

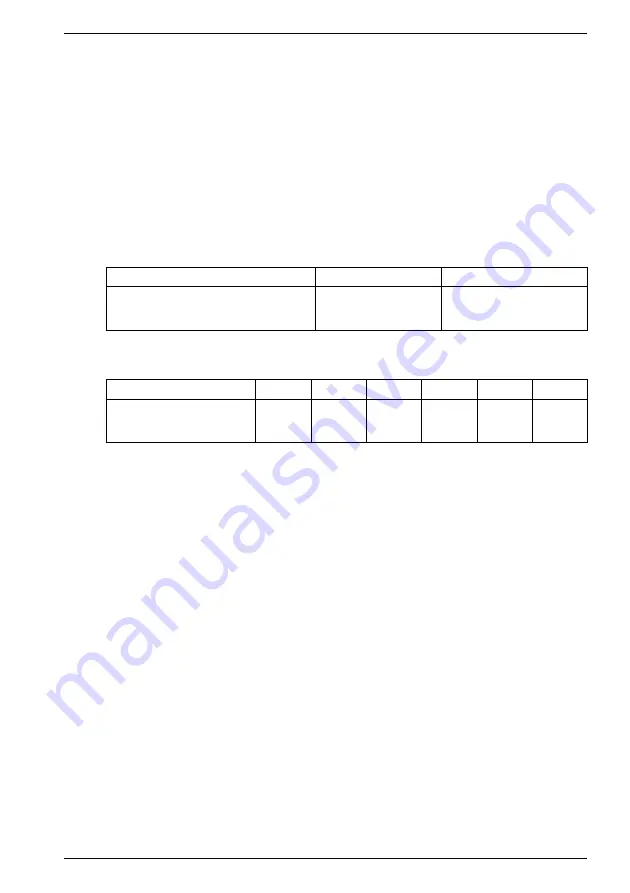

Industry

GasGroup

Gas type (example)

hazardous locations,

excluded use in mines

IIA

IIB

IIC

Propangas

Ethylengas

hydrogenous / acetylen

Temperatur class

T1

T2

T3

T4

T5

T6

Maximaltemperatur °C

Max. Temperaturanstieg

Oberfläche K

450

155

300

155

200

155

135

90

100

55

85

40