Maintenance

6.3 Corrective Maintenance

A5E01083943A AB

84

Siemens AG Operating Instructions 2.02 1FW4

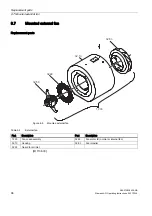

Screwed hub

Two screws should be removed from opposite sides of the connection between the impeller

and the hub in order to attach the pulling device. Do not completely undo the connection

between the impeller and the hub. After separating the impeller and the hub it will be

necessary to rebalance the complete impeller.

Installing

Before mounting the impeller, clean the shaft, feather key and hub and lightly grease them.

The best way to mount the impeller is to use a threaded rod. After fitting the impeller, it is

screwed as far as possible into the motor shaft stub and then mounted with the aid of a nut

and the thrust washer belonging to the impeller. Then secure it with the impeller mounting

screw, thrust washer and a new retaining element.

During installation, always make sure that there is an even gap all around between impeller

and inlet nozzle. [ID 637.01]

6.3.5

Tightening torques for screw and bolt connections

Bolt locking devices

Nuts or bolts that are mounted together with locking, resilient and/or force-distributing

elements must be refitted together with identical, fully functional elements. Always renew

positive-action locking elements.

Threads secured with liquid plastic must be treated accordingly when they are tightened (e.g.

using Loctite 243). Fixing bolts with a clamping length of less than 25 mm must be reinstalled

using suitable retaining elements or soluble locking compound (e.g. Loctite). The clamping

length is taken as the distance between the head of the bolt and the point at which the bolt is

screwed in.

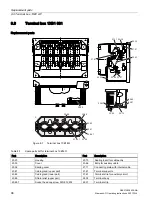

Tightening torques

The bolted connections with metal contact surfaces (end shields, bearing cartridge parts,

terminal box parts bolted onto the stator frame) should be tightened to the following torques,

depending on the thread size.

Table 6-2

Tightening torques (tolerance ± 10%)

M4

M5

M6

M8

M10

M12

M16

M20

M24

A

1.2

2.5

4

8

13

20

40

-

-

Nm

B

1.3

2.6

4.5

10

20

34

83

160

280

Nm

C

3

5

8

20

40

70

170

340

600

Nm

The tightening torques in the different rows apply to the following cases:

Summary of Contents for 1FW4

Page 1: ...Three phase synchronous motor HT direct Type 1FW4 Operating Instructions 01 2009 ht direct ...

Page 2: ...14 01 2009 16 26 ...

Page 24: ......

Page 40: ......

Page 60: ......

Page 88: ......

Page 92: ......

Page 102: ......

Page 108: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......