Maintenance

7.3 Corrective Maintenance

A5E00215731A AD

60

Siemens AG Operating Instructions 2.02 1PL618

②

Torque transmission element

③

Speed sensor

④

Sensor cover

NOTICE

Always disassemble the speed sensor before you dismantle the three-phase motor, in

order to prevent it from becoming damaged.

To disassemble the speed sensor, proceed as follows:

1.

Screw off the sensor cover.

2.

Detach the electrical connection.

–

Pull the cable carefully out of its holder.

–

Pull out the connector.

3.

Remove the screw connections holding the sensor on the end shield.

4.

Pull the sensor off the shaft with the aid of a puller. There are two ways of doing this:

0[

0[

0[

ແ

ໂ

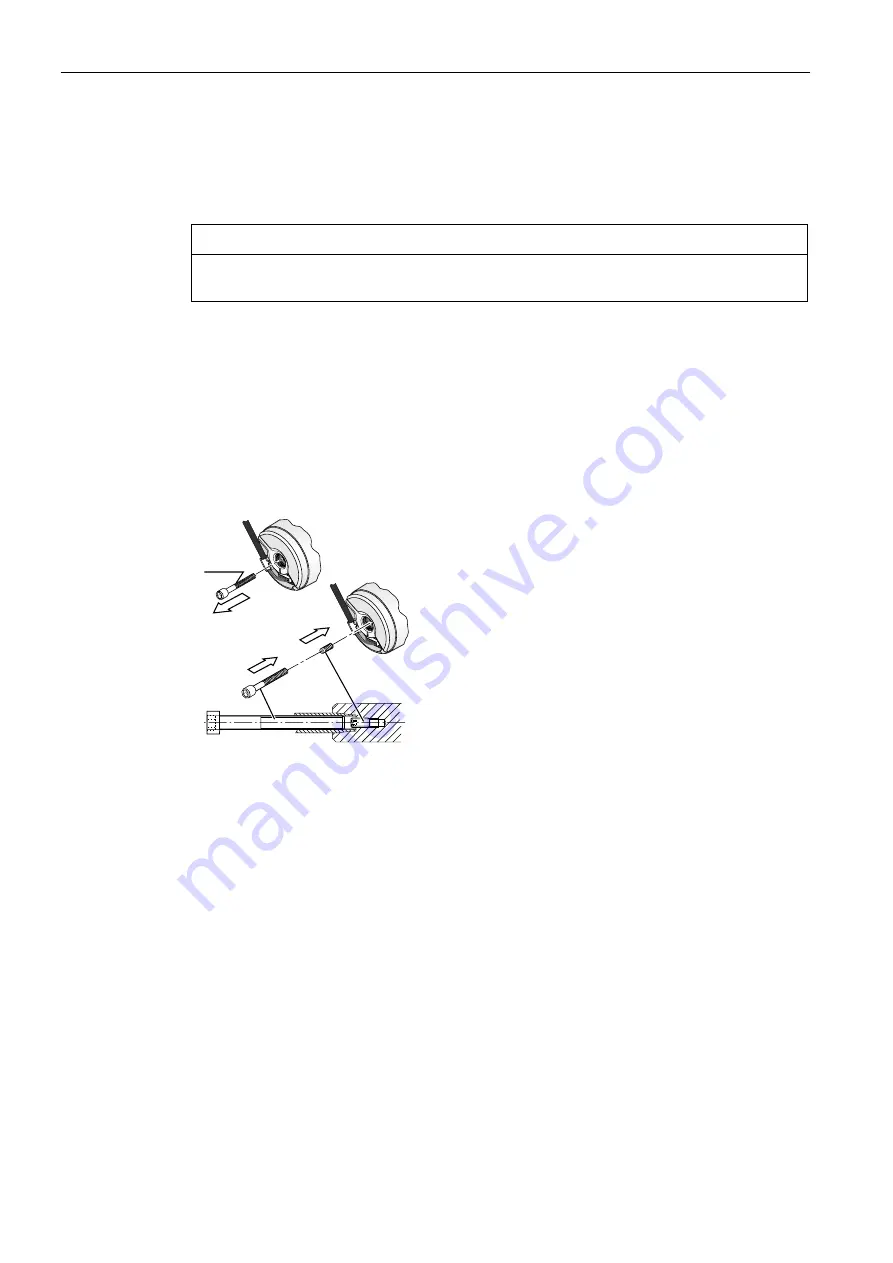

Figure 7-3

Disassembling the speed sensor: forcing off, 1st option

①

Unscrew the screw M5x50.

②

Screw in the screw M5x10 and the screw M6x70 one after the other. This releases

the sensor cone in the motor shaft.

③

Remove the sensor.