Transport, assembly, and connection

3.3 Electrical connection

A5E00264365A

Siemens AG Operating Instructions 2.02 1PL622

33

Final checks

Before closing the terminal box, please check that:

●

the electrical connections in the terminal box are tight and are in full compliance with the

specifications above.

●

the required clearances in air of 10 mm are maintained.

●

no wire ends are standing proud.

●

The inside of the terminal box must be clean and free of any pieces of cable.

●

all seals and sealing surfaces are not damaged.

●

the connecting cables are laid in an open arrangement and the cable insulation cannot be

damaged.

●

cable entries which are not used are sealed and the plugs are tightly screwed in (i.e. so

that they can only be removed using the suitable tools).

●

the right cable glands are fitted with respect to the correct degree of protection, method of

laying, permissible cable diameter etc., as stated in the specifications.

Then close the terminal box.

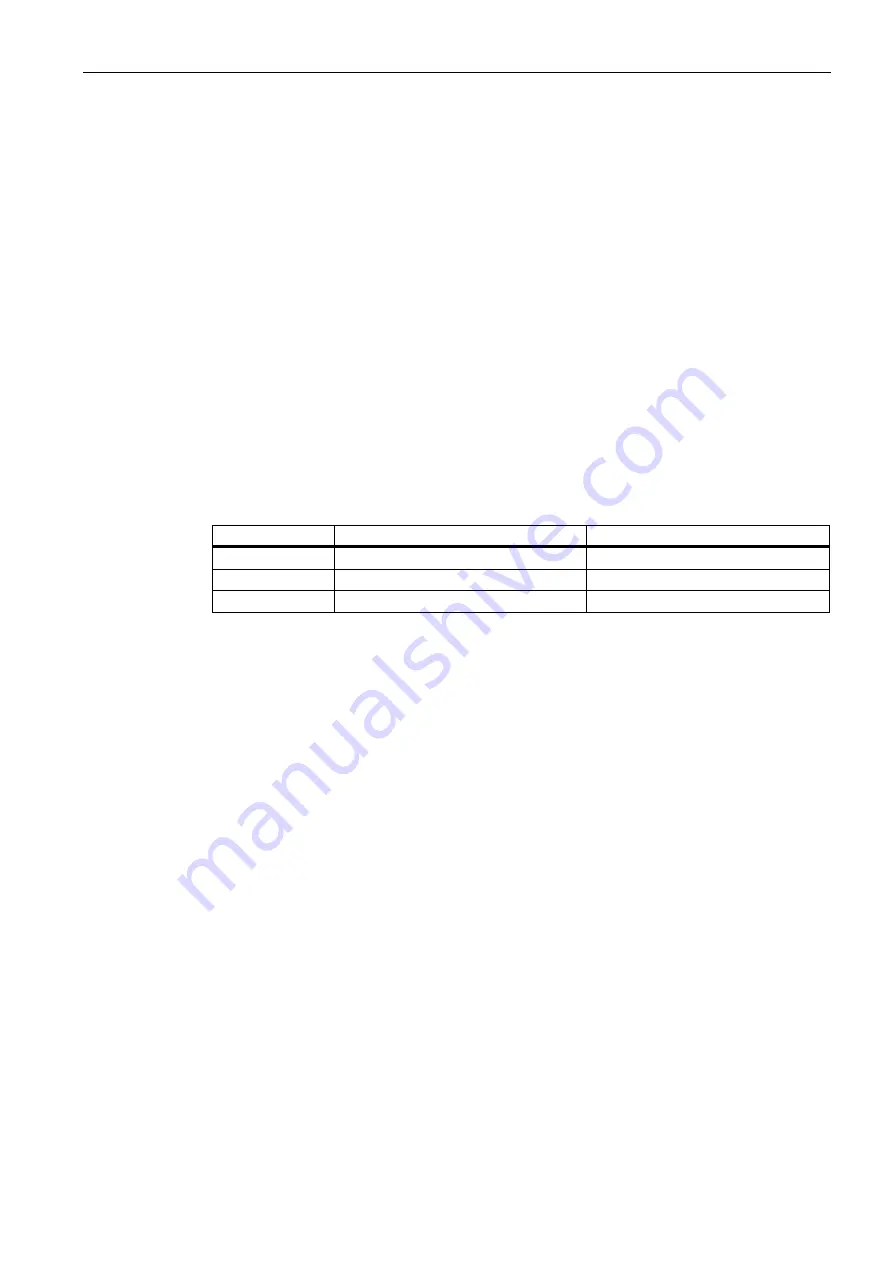

Table 3-4

Tightening torque for the fixing screws on the lid

Bolt

Terminal box type

Tightening torque

M6

1XB7 322

4.5 Nm

M8

1XB7 422

11 Nm

M10

1XB7 700

22 Nm

[ID: 396.01]

3.3.3

Connecting the ground conductor

General

The cross-section of the ground conductor of the motor must comply with the regulations for

electrical installations, e.g. DIN EN IEC 60204-1.

Wiring

Connect-up the ground-conductor in the motor terminal box. For this purpose, a clamping lug

is provided at the appropriately marked connecting point for the ground conductor This lug

can be used for connecting stranded conductors with cable lugs or ribbon cables with an

appropriately shaped conductor end.

The ground conductor must also be connected to the end shield of the motor.

When making connections, ensure that

●

The contact surface is clean and protected with a suitable anti-corrosion agent (e.g. acid-

free Vaseline).

●

the flat and spring washers are located under the bolt head.