Function Blocks

UM353-1B

April

2012

3-4

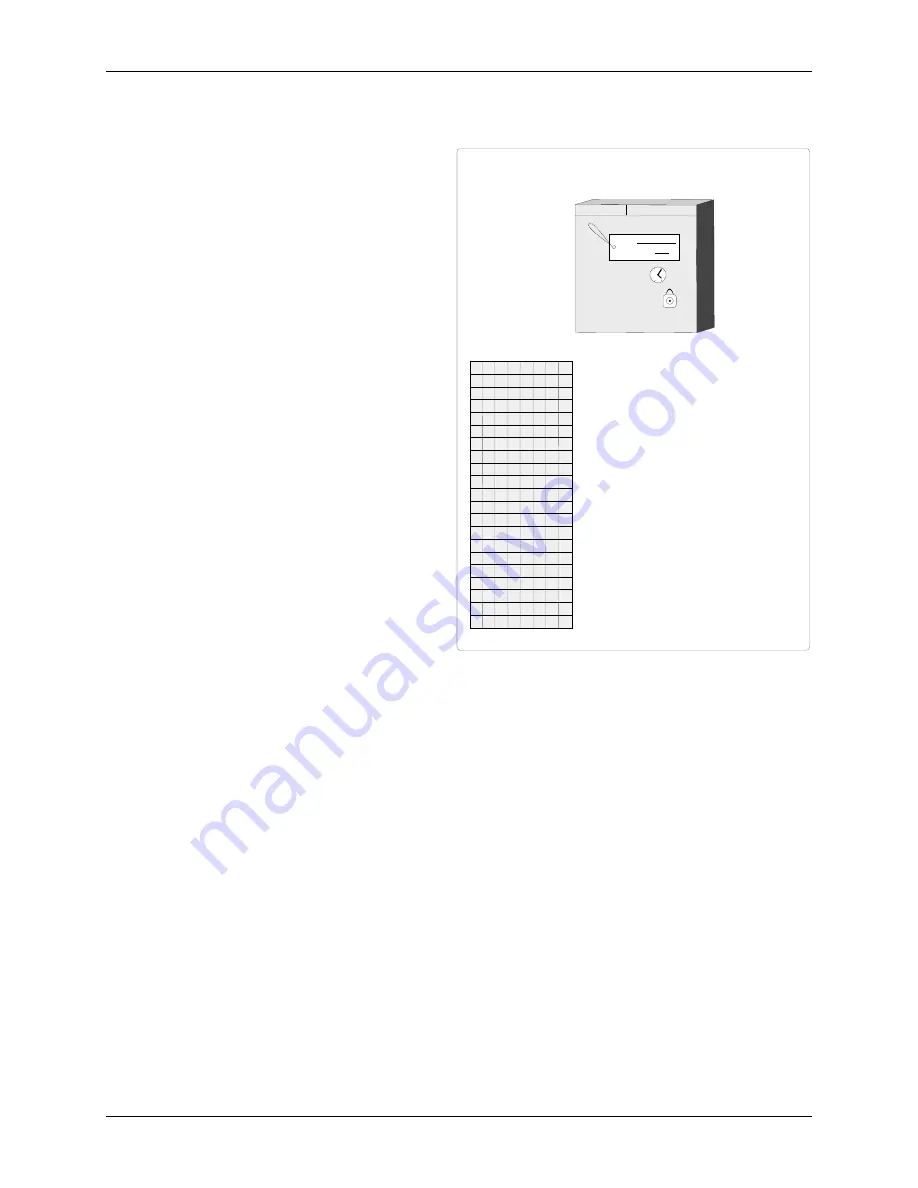

3.1.3 STATN - Station Parameters

The STATN function block enables entry of station

identification and other station related information.

When the station is networked using Modbus, the

address is used by higher level devices to obtain

information from the station. Modbus can range from

1-250 but normally 1-32 is used to correspond to the

total number of devices that can be installed on a single

network.

Once the address has been assigned and higher level

devices have been configured to access information

from the station, changing the address can require

reconfiguration of the higher level device. There may

also be higher level devices that will query and assign

addressing information based on the station tag name.

In this case, a tag name change will also require

reconfiguration of higher level devices. Therefore, it is

important not to change the station identification

without being aware of system consequences.

There are two timers used during power up

initialization: WARM TIM and COLD TIM. The

station takes approximately 15 seconds to perform

power up initialization before the power up time is

evaluated. Set a timer to a value of 20 seconds or

greater, for the timer to be effective. A timer setting of

0 will be considered as infinite (e.g. to always power

up hot, set the warm timer to 0). A setting of 1 through

19 will default to 20. Configurations downloaded with

a warm time setting less than the power up time will be set to the power up time. When the station powers up after a

loss of power but prior to the expiration of the warm timer, the station will execute a Hot Start. If the station powers

up after the warm timer expiration but prior to expiration of the cold timer, the station will execute a warm start. In

all other cases, the station will execute a cold start.

When using Modbus Network communications, the WATCHDOG timer can be set to a value other than 0 to cause

a high WD output from the loop operator display function block when the station does not receive a read command

of the Active Station Event coil (00001) within the timer period. A value of 0 disables the watchdog. A Modbus

communications DELAY time can be entered for both the Display Assembly configuration port and Modbus

terminals NCA/NCB (front and rear ports respectively). This may be necessary when the station responds too

quickly for the modem. Modbus masters may handle IEEE floating point numbers in a different word order. The

IEEE REV parameter allows matching the station to the Modbus master in use.

The CONFG LO (Configuration Lockout) parameter and PARAM LO (Parameter Write Lockout) parameter

provide a method for locking out configuration transfers and parameter read/writes from a PC over a Modbus or

Ethernet network. A 0 allows writes, a 1, 2, or 3 prevents writes. (There is no difference in operation in selecting a

1, 2, or 3.)

The 8-digit SERIAL # of the station is stored in memory and can be viewed when this parameter is displayed. If

only seven digits are seen, assume a leading zero.

BAUD rate parameters set the Modbus port characteristics; see Table 3-2. The network Modbus port at terminals

NCA and NCB, the rear port, is RS485 and uses the assigned station address. The configuration port, the front port,

is RS232 and uses an address of 1.

STATION PARAMETERS

E

Station

ADDRESS

(H)

.................... 0 - 250 (0)

STATION PARAMETERS

STATN

S S

D D

G

A

T

Station

TAG

(S)

.................. 12 Char ASCII (PAC 353)

ADDRESS: 24

TAG: UNIT NO. 3

A

R

IDENTIFICATION TAG

STATION TIMERS

W A R M

T I M

WARM TIM

er (sec)

(S)

............. 0 - 999999 (20)

COLD TIM

er (sec)

(S)

.............. 0 - 999999 (100)

C O L D

T I M

W A T C

D O G

H

WATCHDOG

timer (sec)

(S)

........ 0 - 1000 (0)

12

6

3

9

C O N F

L O

M

P A R

O

G

L

CONF

i

G

uration

L

ock

O

ut

(S)

.......... 0/1/2/3 (0)

(1)

PARAM

eter

L

ock

O

ut

(S)

............... 0/1/2/3 (0)

(1)

A

PC WRITE LOCKOUT

S E R I A L

#

SERIAL #

(R)

...................... 0 to 99999999 (xxxxxxxx)

D

R P

B

U

A

D

F P

B

U

A

S

F P

T

R

R

ear

P

ort

BAUD

rate

(S)

.......... (Table 3-2) (5)

F

ront

P

ort

BAUD

rate

(S)

......... (Table 3-2) (6)

F

P

RTS

/CTS

handshaking (S) .......

(Table 3-2) (1)

BAT

tery

OK

(R)

..............................

NO/YES

H W

P R E S

H

ard

W

are

PRES

ent

(R)

.............(Table 3-3)

C T

B A S E

C

ycle

T

ime

BASE

msec

(R)

..........

20 to 2000

C T

B

A S

I

C

ycle

T

ime

BIAS

msec

(H)

................ 0 to 1000

(0)

C M

V M

A V A I L

A V A I L

C

onstant

M

em

AVAIL

able

bytes

(R)..

varies w/ software rev

V

olitile

M

em

AVAIL

able

bytes

(R)..

...

varies w/ software rev

K

O

T

A

B

I E E E

R E V

IEEE

Floating Point

REV

erse

(S)

. NO/YES (YES)

R P

D E L A Y

R

ear

P

ort

DELAY

(S)

.......... 0 - 1000 msec (0)

F P

D E L A Y

F

ront

P

ort

DELAY

(S)

......... 0 - 1000 msec (0)

C O N F G

T O

CONF

i

G

uration

T

ime

O

ut

(H)

.........

NO/YES (YES)

(1)

- 0-No Lock Out, Writes Allowed; 1, 2, or 3-Lock Out Enabled, Writes Not Allowed [r2 B-Level]

Summary of Contents for 353

Page 12: ...Contents UM353 1B x April 2012 ...

Page 22: ...Introduction UM353 1B April 2012 1 10 ...

Page 30: ...Configuration Overview UM353 1B April 2012 2 8 ...

Page 122: ...Function Blocks UM353 1B April 2012 3 92 ...

Page 168: ...Data Mapping UM353 1B April 2012 6 28 ...

Page 204: ...Controller and System Test UM353 1B April 2012 9 8 ...

Page 222: ...Calibration UM353 1B April 2012 11 4 ...

Page 226: ...Circuit Description UM353 1B April 2012 12 4 ...

Page 238: ...Model Designation and Specifications UM353 1B April 2012 13 12 EC Declaration of Conformity ...

Page 240: ...Model Designation and Specifications UM353 1B April 2012 13 14 ...

Page 244: ...Abbreviations And Acronyms UM353 1B 14 4 April 2012 ...