UM353-1B

Function Blocks

April 2012

3-39

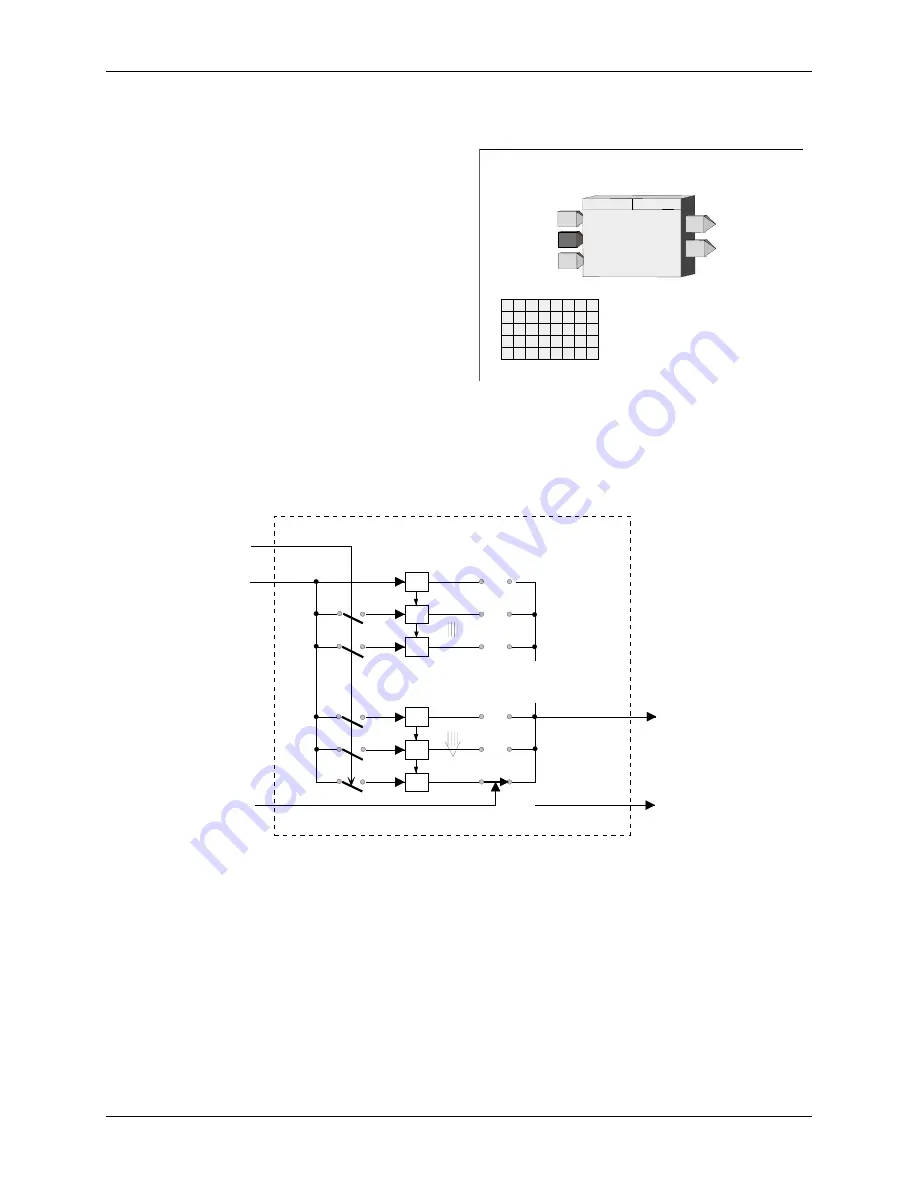

3.2.34 DTM_ - Dead Time Table

DTM_

function blocks provide shift registers to hold the

analog input signal A for a period of time and shift it from

register to register to provide an overall delay between

input and output as configured in parameter DEADTIME.

Input AT can be used to adapt the DEADTIME to an

external signal. The actual shift register used as the block

output will equal the whole value of input AT (e.g. 0.184 =

register 0, 1.897 = register 1).

Output MA will provide the moving average of register 0

to the output register divided by the number of registers

[e.g. output register = 50, MA = (R0+R1+R2+......+R50)/51].

Input E asserted high (1) will enable the operation of the DTM block. When this input is not configured, it will be

set high. A low (0) input will cause all registers and the outputs to equal the input A.

POWER UP - During a warm or cold start, all outputs will be initialized at 0 and all registers will be initialized to

the value of the input on the first scan.

BLOCK DIAGRAM

A

O1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

SH

IF

T R

EG

IST

E

R

S

E

AT

A

daptive

T

ime

A

nalog Input

E

nable

O

utput

1

n

n-1

n-2

n-48

n-49

n-50

Register 0

Register 1

Register 50

MA

M

oving

A

verage

.

A

nalog Input

DEAD TIME

E

T

D E

I N

U

E

DEAD TIME

(S)

........ 0.0 to 10000 min. (0.0)

INPUT E

(H)

.......

loop tag.block tag.output (null)

O1

O

utput

1

DEAD TIME

DTM_

ESN = 000

I M

D

T

P

A

E S N

E

xec.

S

eq.

N

o.

(H)

.............. 001 to 250

E

nable

E

A

daptive

T

ime

AT

MA

M

oving

A

verage

A

I N

U

A

T

P

I N

U

T

T

P

INPUT A

(H)

.......

loop tag.block tag.output (null)

INPUT AT

(H)

.....

loop tag.block tag.output (null)

A

Summary of Contents for 353

Page 12: ...Contents UM353 1B x April 2012 ...

Page 22: ...Introduction UM353 1B April 2012 1 10 ...

Page 30: ...Configuration Overview UM353 1B April 2012 2 8 ...

Page 122: ...Function Blocks UM353 1B April 2012 3 92 ...

Page 168: ...Data Mapping UM353 1B April 2012 6 28 ...

Page 204: ...Controller and System Test UM353 1B April 2012 9 8 ...

Page 222: ...Calibration UM353 1B April 2012 11 4 ...

Page 226: ...Circuit Description UM353 1B April 2012 12 4 ...

Page 238: ...Model Designation and Specifications UM353 1B April 2012 13 12 EC Declaration of Conformity ...

Page 240: ...Model Designation and Specifications UM353 1B April 2012 13 14 ...

Page 244: ...Abbreviations And Acronyms UM353 1B 14 4 April 2012 ...