Transport, storage and packing

10

9229 9947 176 0C

2013-03-28

Unpacking (II)

Working equipment

Required tools:

- Knife/scissors

- Lifting equipment with lifting gear.

Opening the transport unit

• Place the transport unit on a level, non-slip and pressure-resistant surface.

• Remove lifting gear or transport means.

• Remove foil.

• Check the vacuum circuit-breaker for damage.

• Remove all tensioning belts and bits of fastening wood.

• Remove timber between pole plate and beam.

• Hook crane hooks into the openings on the mechanism box.

• Carefully lift vacuum circuit-breaker.

Note

Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks,

flakings, bent metal parts, damaged plug-in contacts, tears or bare cables.

Send it back in its original transport unit (see “Reusing the transport unit”,

page 12).

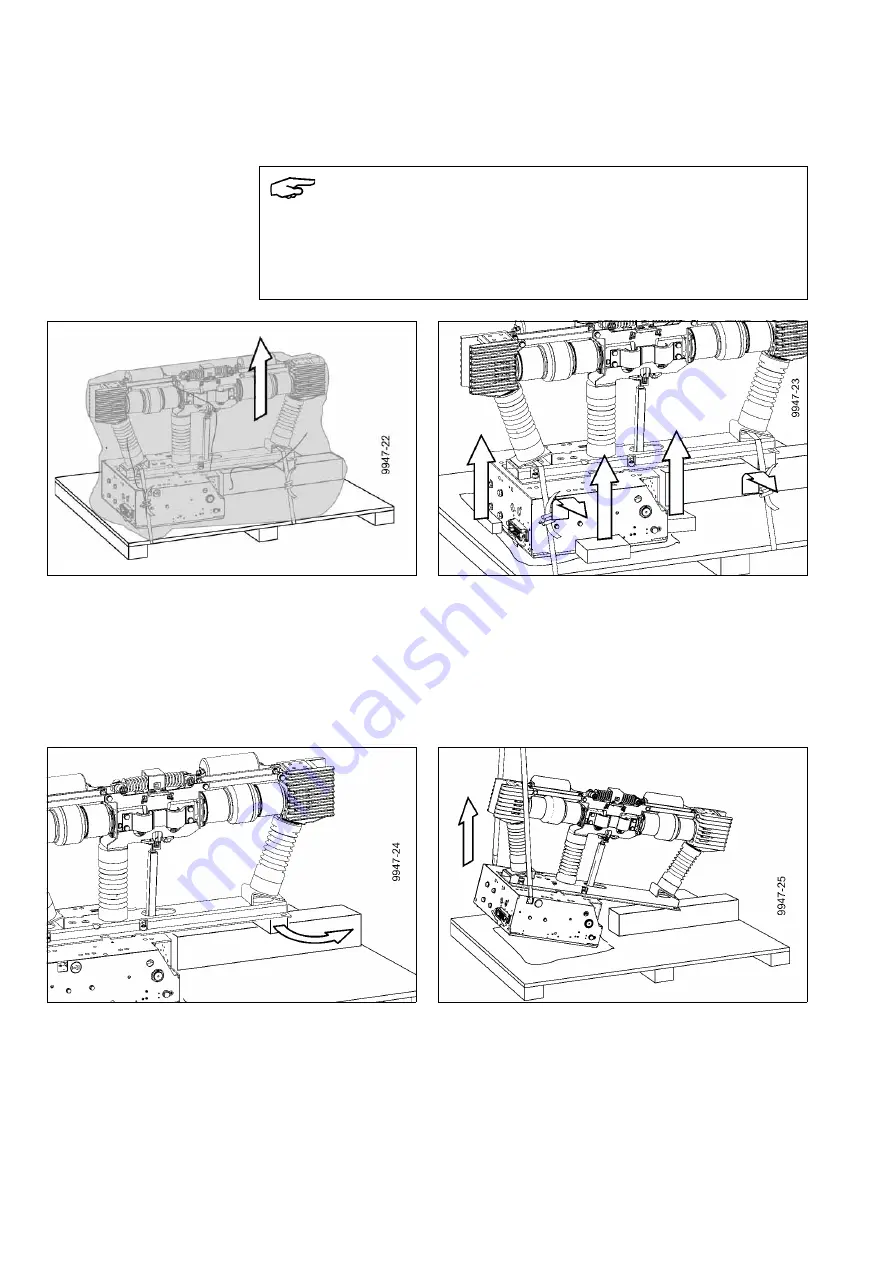

Fig. 10

Removing foil

Fig. 11

Removing tensioning belts and bits of

fastening wood

Fig. 12

Removing squared timber

Fig. 13

Lifting