100

6 Maintenance

6.4.11.3 Functional

Check, Anti-Pumping Feature

Circuit-breaker in closed position: (closing spring tensioned)

- Give electrical CLOSE command and keep button pressed in (maintained command)

The circuit-breaker must only switch off.

6.4.11.4 Function Check of Enforced Triple-Pole Operation Feature

Close all three poles of the circuit-breaker and open one of them by actuating the operating trip 18.8 (Fig. 70).

After the time set on the enforced triple-pole operation relay on the plant side has elapsed, the other two circuit-

breaker poles must also be tripped by the enforced triple-pole operation contactor. Carry out this test in a similar

manner on the other two circuit-breaker poles.

6.4.12

Check of Motor Control

Check whether after a closing operation the motor is activated by a limit switch, and, whether after the charging

process of the closing spring the motor is deactivated via a limit switch.

Perform this check at all poles.

6.4.13

Measuring the SF

6

Gas Humidity Content

Before putting the breaker into operation, the humidity of the SF

6

-gas must be checked. For this a commercially

available dew point measuring instrument with °C scale can be used. The maximum permissible dew point

temperatures at operating pressure corresponding to the permissible humidity are stated below.

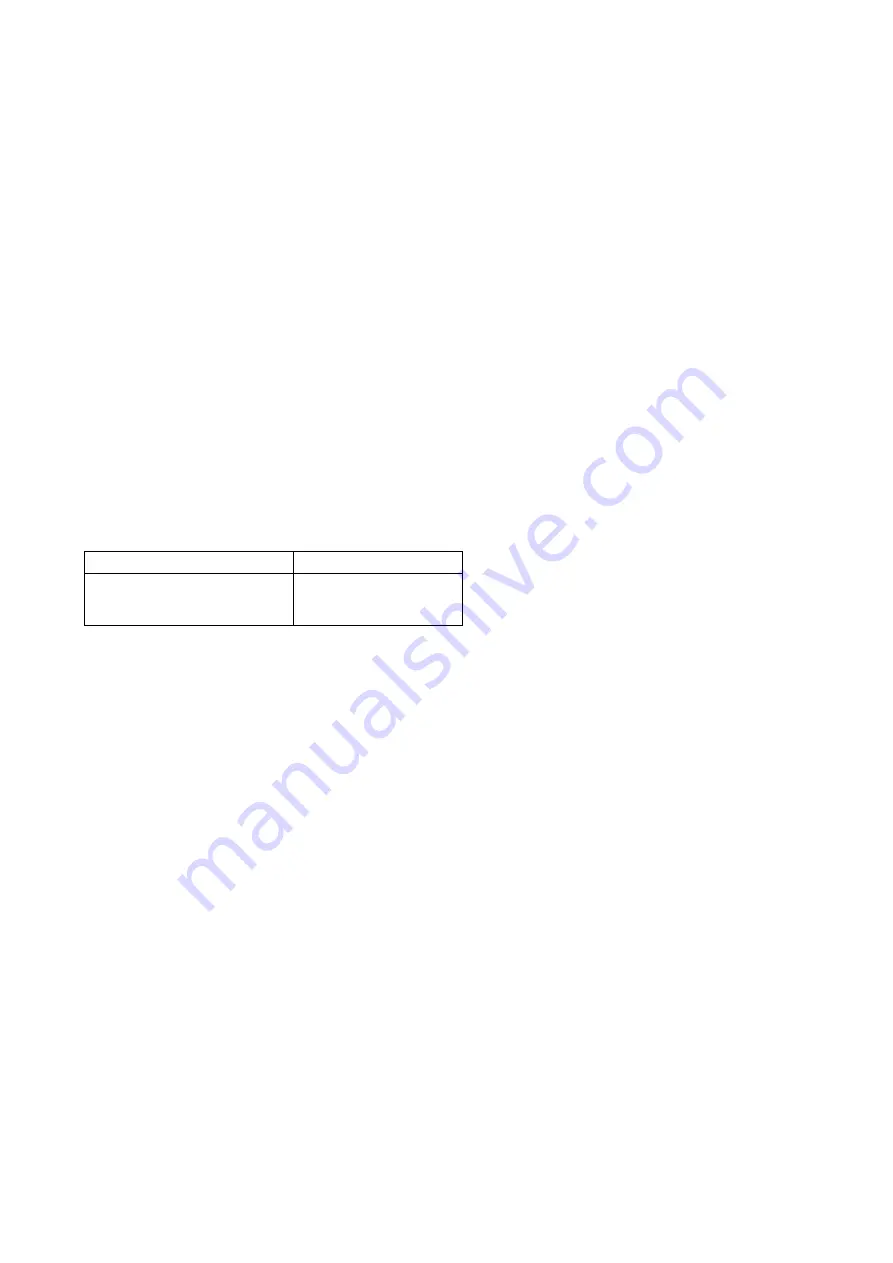

Critical humidity limit

-5°C (+23°F)

Maximum permissible humidity

during commissioning/in operation

-10°C(+14°F)

Table 15 Dew point

If the measured dew point temperature lies above -10°C/+14°F, then the SF

6

gas must dried using a service unit.

6.4.14 Measuring the SF

6

Air Content

When the breaker has been filled with new gas and following maintenance work, the air content should not be

more than 5 % as measured with the SF

6

percentage instrument 3-027 from DILO (D-87727 Babenhausen,

Federal Republic of Germany). This instrument measures the SF

6

volumetric portion (at least 95 %).