English

4/1

Siemens plc 1993

4. CONNECTING UP

Hazardous voltages of over 750 V are used in the operation of this equipment and can cause

severe personal injury or loss of life. The following precautions must be observed to reduce risk

of injury or death:

•

Only qualified service technicians should be allowed to test and repair the equipment or

parts thereof.

•

Keep all covers in place during normal operation.

•

Defective discharge resistors of the dc–link circuit capacitors cause hazardous voltages to

remain in the unit for some time. Make sure that the voltage has dropped below 50 V before

touching any electrical contacts. Non–observance can lead to severe or fatal injury.

•

During commissioning, should it be necessary to make measurements with the power

turned on, do not touch any electrical contacts during such work and keep one hand

completely free and outside the electrical circuitry.

•

Ensure that test equipment is in good and safe operating condition.

•

Stand on an ESD–approved insulated surface while performing commissioning work with

the power on, being sure not to be grounded.

•

When working on the connected motor or motor supply cable, ensure that the input power

switch of the equipment for the external feed breaker is padlocked in the OFF position.

•

All work on the equipment and its installation must be carried out in accordance with the

locally applicable electrical wiring regulations. This includes proper grounding to ensure that

no accessible part of the equipment is at line or any other hazardous potential.

•

The User is responsible for installation of the motor, drive controller, transformer and other

devices in accordance with regulations and local safety codes which may apply. Pay special

attention to proper conductor sizing, fusing, grounding, isolating and disconnecting means

and to overcurrent protection.

•

Failure to ground the inverter properly can result in the surface of the equipment carrying

hazardous voltages which may cause severe injury, loss of life or considerable damage to

property.

WARNING

4.1 Mains Input/Motor Connections

Only qualified personnel who are familiar with the equipment, its operating instructions and

requirements should be allowed to install and operate this equipment.

Incorrect connection of the mains and motor leads (such as connecting the input to the output

or connecting excessive supply voltages to the input) will result in damage to the inverter.

WARNING

First, ensure that an input power supply of the correct voltage and current rating is available

(see section 2). Next,

ensure that the specified current rating fuse/overload circuit–breaker is connected between the input power

source and the inverter.

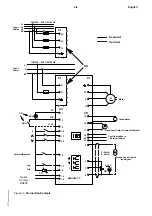

The power inputs should be connected to X1 on the lower printed circuit board using a three or four–core cable and

the motor should be connected using a four–core cable, both suitable for the currents specified in section 2.1. To

connect the cable, first remove the plastic cover of the drive by undoing the retaining screws or by levering the

retaining clips inwards with a screwdriver. Next, connect the cable to the terminal block X1 as shown in Figure 3.

Summary of Contents for 6SE2101-1AA01

Page 5: ...English vi Siemens plc 1993 This page intentionally blank ...

Page 11: ...English 2 2 Siemens plc 1993 This page intentionally blank ...

Page 53: ...English 7 18 Siemens plc 1993 This page intentionally blank ...

Page 59: ...Deutsch vi Siemens plc 1993 Diese Seite bleibt absichtlich frei ...

Page 65: ...Deutsch 2 2 Siemens plc 1993 Diese Seite bleibt absichtlich frei ...

Page 107: ...Deutsch 7 18 Siemens plc 1993 Diese Seite bleibt absichtlich frei ...