8

05.01

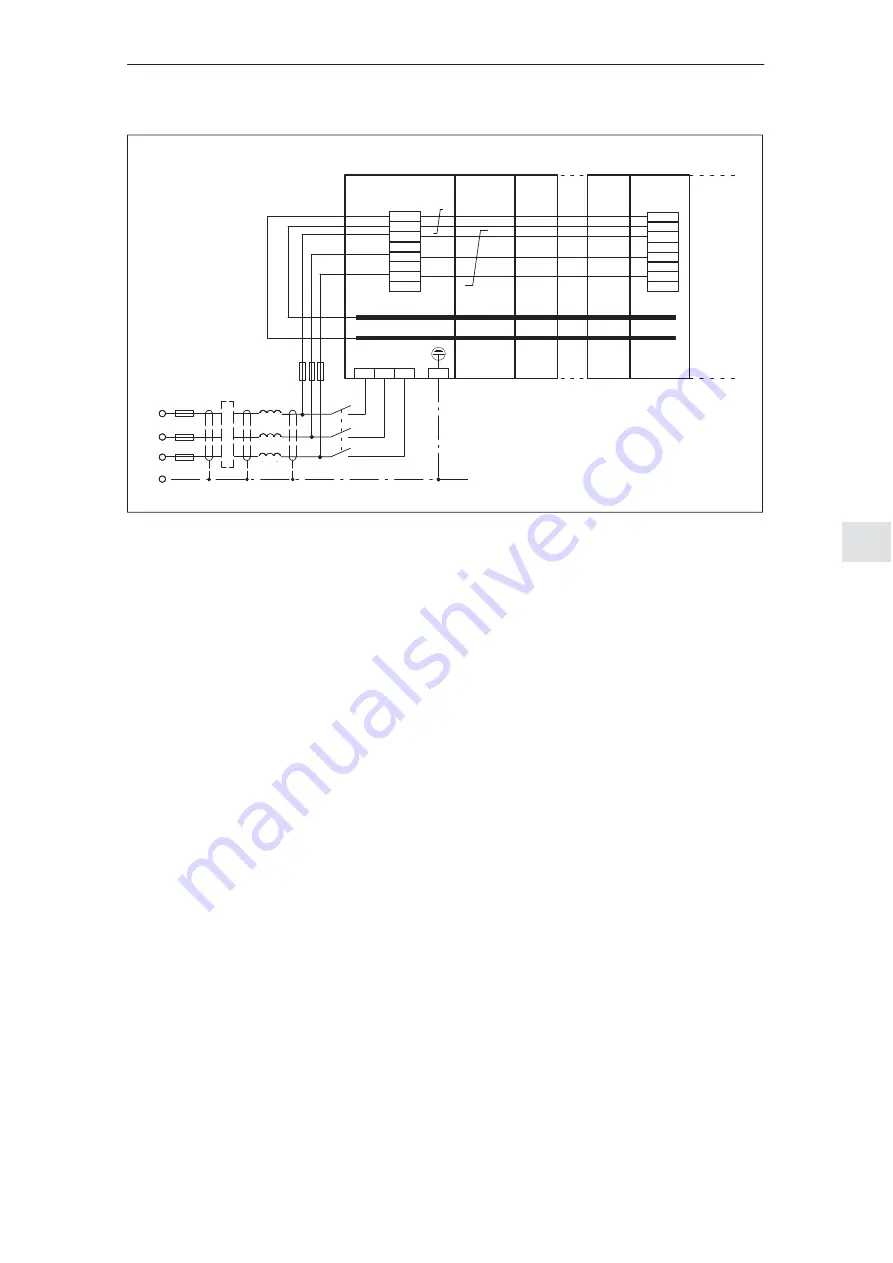

8.15 Examples of correctly and incorrectly connecting NE

8-319

©

Siemens AG 2012 All Rights Reserved

SIMODRIVE 611 Configuration Manual (PJU) – 02/2012 Edition

L2

e.g. NCU

PMxx

P600

M600

U1

V1 W1

PE

PMxx

X181

M500

P500

2U1

1U1

2V1

1V1

2W1

1W1

X181

M500

P500

2U1

1U1

2V1

1V1

2W1

1W1

Correct for NE

16 kW!

L1

L

K

F

N

(X A)

Filter (X kW)

PE

L3

Schematic diagram

Six–conductor connection

to the line supply

with DC link buffering

NE

MM

F

N

(T10 A)

Twisted

cable

Fig. 8-36

Example for correct six–conductor connection to the line DC link connection

8 Important Circuit Information

02.12